Introduction

Magnets are everywhere in our modern world, especially in electric motors. From electric vehicles and drones to wind turbines and industrial robots, magnets are the driving force behind motion and precision. Among them, NdFeB magnets—short for Neodymium Iron Boron—are the strongest type of permanent magnets available today.

But here’s the thing: not all NdFeB magnets are the same. Depending on how hot the environment gets, some magnets will hold up better than others. That’s why picking the right grade of magnet matters—especially in high-temperature motors, where overheating is a real risk.

In this article, we’ll explain the difference between two popular NdFeB magnet types: N45SH and N52M. By the end, you’ll know which one is better for your motor project—and why.

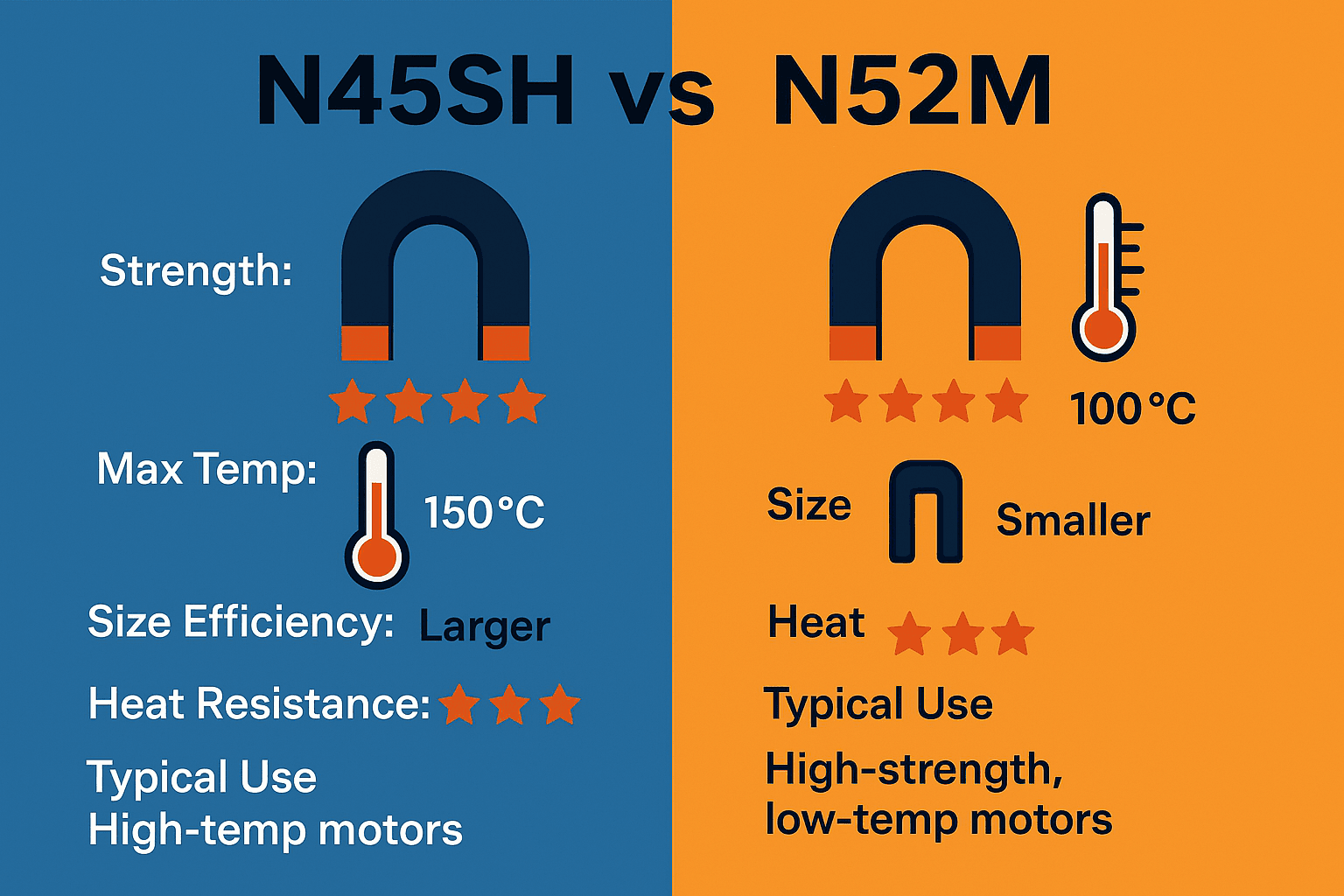

What Do “N45SH” and “N52M” Mean?

Let’s break down these names in simple terms:

- The “N” stands for Neodymium.

- The number (like 45 or 52) tells you how strong the magnet is. The bigger the number, the stronger the magnet.

- The letters at the end tell you how much heat the magnet can handle.

Here’s what that looks like:

| Grade | Strength | Max Working Temperature |

|---|---|---|

| N52M | Very Strong | Up to 100°C (212°F) |

| N45SH | Strong | Up to 150°C (302°F) |

So, N52M is stronger, but N45SH can take the heat better.

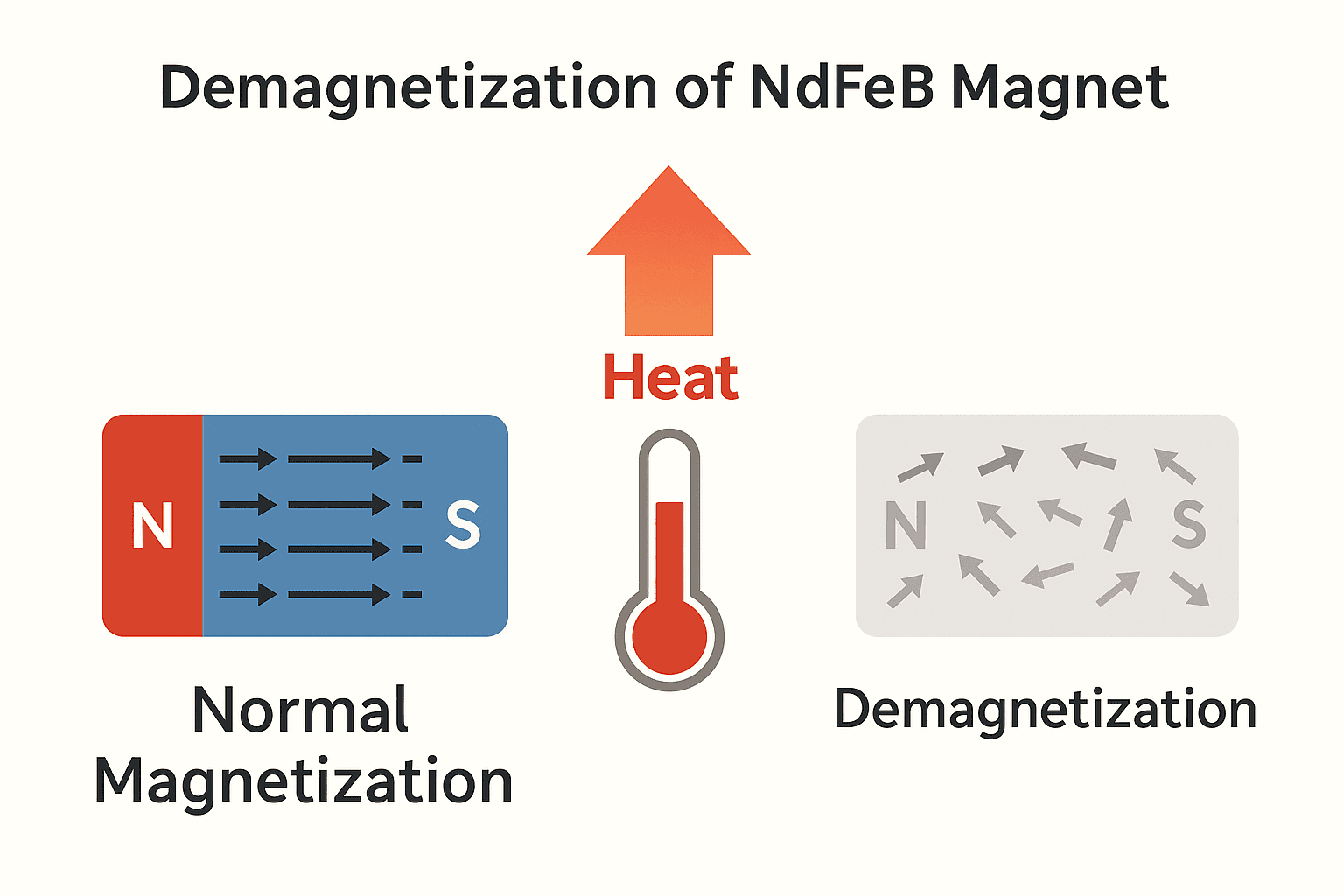

Why Does Temperature Matter?

Electric motors can get hot—really hot—especially when they:

- Run for a long time

- Handle heavy loads

- Are packed into small spaces

- Don’t have great cooling

If the magnet inside a motor gets too hot, it can lose its magnetism—sometimes permanently. That means the motor will slow down, lose power, or even stop working.

This is why temperature resistance is just as important as magnetic strength.

N52M: When Strength Is Everything

Let’s start with N52M.

What’s Good About It?

- It’s one of the strongest magnets you can buy.

- You can make smaller motors that are still powerful.

- Great for applications where size and weight matter.

Where It Works Well:

- Drones

- RC cars

- Precision tools

- Compact robotics

- Fans and blowers in cool environments

The Limitation?

N52M only works well up to about 100°C (212°F). That might sound like a lot, but in many motors, the temperature can go higher than that—especially if the cooling isn’t perfect.

So, if your motor stays cool, N52M is a great pick. If it runs hot? Not so much.

N45SH: Built for the Heat

Now let’s look at N45SH.

What’s Good About It?

- Can handle up to 150°C (302°F) without losing magnetism.

- More stable and reliable in hot conditions.

- Designed to resist demagnetization, even when hot.

Where It Works Well:

- Electric vehicle motors

- Industrial servo motors

- Wind turbine generators

- Aerospace components

- High-speed or high-load applications

The Limitation?

It’s not as strong as N52M. So, your motor might need to be slightly bigger to get the same power.

But in return, you get peace of mind: the magnet won’t fade when things heat up.

Real-World Example: Which One to Choose?

Let’s say you’re designing a motor for an electric scooter.

- If the motor only runs at moderate speeds and is in open air (with cooling fans), the inside of the motor might stay under 90°C.

- ✅ N52M would work well here.

But what if the scooter goes uphill, carrying a heavy rider, in hot weather, and the motor is tightly packed with poor airflow?

- The inside could easily reach 130°C or more.

- ❌ N52M might start to fail.

- ✅ N45SH would be the safer option.

It’s all about understanding the working temperature of your application.

What Happens If You Pick the Wrong Magnet?

If you use a magnet that can’t handle the heat, you risk:

- Reduced motor power

- Inconsistent performance

- Permanent damage

- Costly replacements

It’s like putting summer tires on your car in the middle of winter—they just won’t work properly, and it’s dangerous.

What About Cost?

Many people ask: Is N45SH more expensive than N52M?

The answer is: It depends.

- N52M has more neodymium, which is expensive.

- N45SH uses more heavy rare earth elements (like dysprosium or terbium) to improve heat resistance, which are also pricey.

In the end, their prices are often similar. But using the wrong one can cost much more in failures, downtime, or redesigns.

So don’t just look at price—think about long-term reliability.

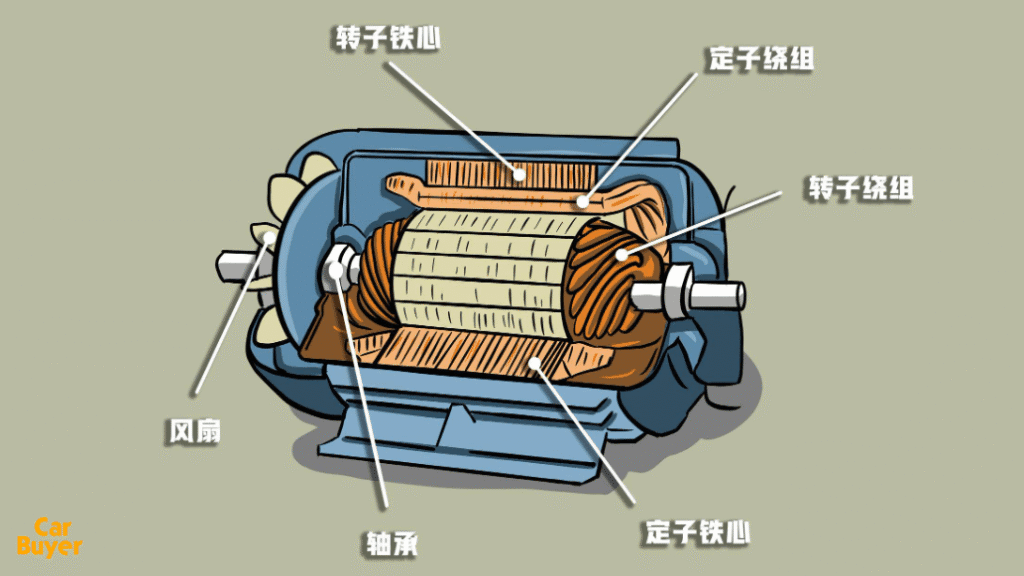

How Do These Magnets Look in a Motor?

Here’s a simple comparison:

| Feature | N52M | N45SH |

|---|---|---|

| Strength | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| Heat Resistance | ⭐⭐ | ⭐⭐⭐⭐⭐ |

| Size Efficiency | Smallest possible | Slightly bigger needed |

| Cost | Medium-High | Medium-High |

| Best for | Cool, compact motors | Hot, heavy-duty motors |

If your motor has to be as small as possible and won’t get too hot—go with N52M.

If your motor will run hot or work in tough environments—choose N45SH.

Other Things to Consider

1. Cooling System

If your motor has a strong cooling fan or liquid cooling, you might be able to use N52M even in warmer environments.

But if it’s passively cooled, or inside a sealed box—play it safe with N45SH.

2. Duty Cycle

A motor that runs non-stop for hours will get hotter than one that runs in short bursts. Long runs = more heat = more need for heat-resistant magnets.

3. Motor Size Constraints

If there’s very limited space and you need the maximum magnetic power, N52M helps you keep the motor compact.

4. Load Type

Heavy loads or high torque often require magnets that can withstand demagnetizing forces. N45SH has stronger resistance in this regard.

Still Not Sure Which to Use?

Here’s a rule of thumb:

- If your motor stays under 100°C most of the time:

→ Go with N52M for the best strength. - If your motor often goes over 100°C:

→ Choose N45SH for safe and stable operation. - If you’re unsure of your motor’s temperature:

→ It’s safer to choose N45SH to avoid surprises.

What Magnetstek Can Offer

At Magnetstek, we understand that choosing the right magnet isn’t always easy. That’s why we:

- Help you select the best grade for your needs

- Provide custom magnet shapes and sizes

- Offer magnets with special coatings for corrosion or heat protection

- Supply both N45SH and N52M in various formats (blocks, arcs, rings, etc.)

- Deliver consistent quality and testing for motor applications

We’re here to help you build motors that last—and perform exactly as expected.

Conclusion

Choosing between N45SH and N52M comes down to a simple question:

Do you need more strength, or more heat resistance?

- Pick N52M if your motor stays cool and needs maximum magnetic power.

- Pick N45SH if your motor runs hot and reliability is critical.

Both are excellent NdFeB magnet grades, but used in the wrong place, they can cause problems.

By understanding your motor’s working environment—and using this guide—you can make the right choice with confidence.

Let Magnetstek help you power your next motor project the smart way.

Related Products

SmCo Magnets