Introduction

NeFeB Radial Ring magnets, more accurately referred to as NdFeB Radial Ring magnets, are a specialized type of permanent magnet known for their radial magnetization pattern and ring-shaped structure. These magnets belong to the family of sintered neodymium-iron-boron (NdFeB) magnets, which are renowned for their exceptional magnetic strength, high energy density, and versatility in modern industrial applications. The radial orientation of their magnetic fields makes them particularly suitable for applications requiring rotational symmetry, precise angular control, and high torque density.

This article delves into the definition, manufacturing processes, applications, and challenges associated with NdFeB Radial Ring magnets. By exploring their unique properties and the advanced techniques used in their production, we aim to provide a comprehensive understanding of their significance in various industries.

1. Definition and Key Features

1.1 What Are NdFeB Radial Ring Magnets?

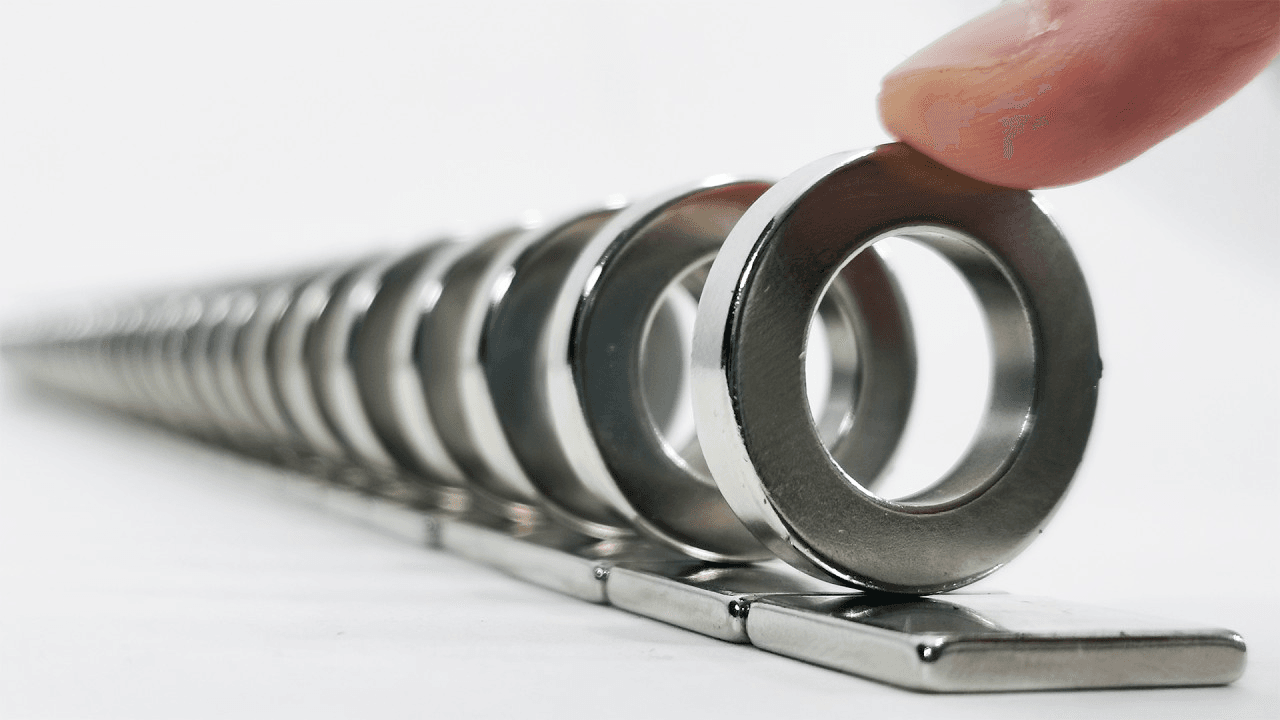

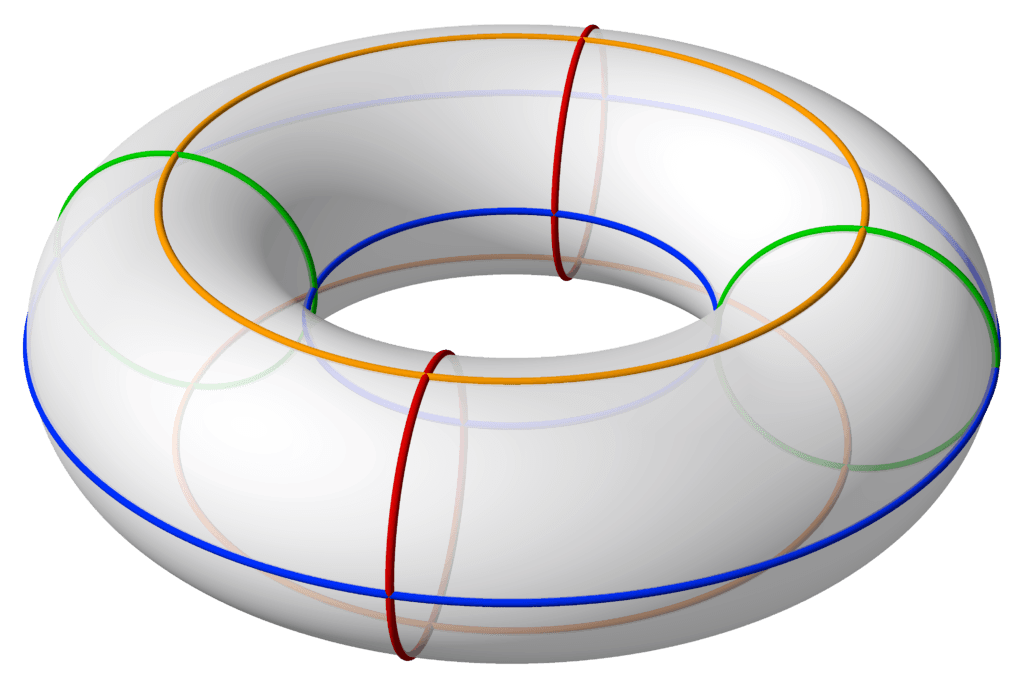

NdFeB Radial Ring magnets are permanent magnets characterized by their ring-shaped geometry and radial magnetization pattern. Unlike conventional axially magnetized rings, where the magnetic poles are aligned along the vertical axis, radial ring magnets have their poles oriented radially around the circumference of the ring. This unique orientation allows for optimized magnetic flux distribution, making them ideal for applications involving rotational motion or precise angular control.

1.2 Key Features

The following are the key features that distinguish NdFeB Radial Ring magnets:

- High Energy Product: NdFeB magnets are known for their exceptional magnetic energy density, which is the highest among all commercially available permanent magnets. This property enables the design of compact and lightweight devices without compromising performance.

- Radial Anisotropy: The radial orientation of the magnetic field is achieved through specialized sintering and pressing techniques. This ensures uniform magnetic field distribution and enhances the efficiency of devices that rely on rotational symmetry.

- Temperature Resistance: NdFeB magnets are available in various grades, such as N42SH and N35EH, which offer stability in high-temperature environments. This makes them suitable for applications in motors, generators, and other high-performance systems.

- Mechanical Strength: Despite their brittleness, NdFeB magnets can be engineered to withstand mechanical stresses through protective coatings and advanced manufacturing techniques.

2. Manufacturing Process

The production of NdFeB Radial Ring magnets involves a combination of advanced techniques to achieve precise magnetic orientation and structural integrity. Below, we outline the key steps in the manufacturing process.

2.1 Raw Material Preparation

The production of NdFeB magnets begins with the preparation of raw materials, which include neodymium, iron, and boron. These elements are carefully weighed and mixed in specific proportions to achieve the desired magnetic properties.

2.2 Powder Metallurgy

The mixed raw materials are then subjected to a process called powder metallurgy, which involves the following steps:

- Melting and Alloying: The raw materials are melted in a vacuum induction furnace to form a homogeneous alloy.

- Milling: The alloy is rapidly cooled and ground into a fine powder.

- Pressing: The powder is pressed into a compact shape using a die. During this step, a magnetic field is applied to align the crystal grains in the desired orientation (radial, in the case of radial ring magnets).

2.3 Sintering

The pressed compacts are then sintered in a vacuum or inert gas atmosphere at high temperatures. This process densifies the material and enhances its magnetic properties.

2.4 Radial Rolling Process

A patented method known as radial ring rolling is used to achieve the precise geometry and magnetic orientation required for radial ring magnets. This process involves the following steps:

- Ring Blank Preparation: A ring-shaped blank is prepared from the sintered material.

- Rolling: The ring blank is rolled between a rotating main roll and a mandrel. The gap between the roll and mandrel is progressively reduced, causing the ring to deform radially.

- Dynamic Adjustment: The rotation speed of the mandrel is dynamically adjusted based on the feeding speed of the main roll to ensure uniform deformation and minimize defects.

This method improves material utilization and mechanical properties, making it critical for the production of high-performance radial ring magnets.

2.5 Machining and Coating

After the rolling process, the magnets are machined to achieve the desired dimensions and surface finish. They are then coated with protective layers, such as nickel-copper-nickel (Ni-Cu-Ni), to prevent corrosion and mechanical damage.

2.6 Magnetization

The final step in the manufacturing process is magnetization, where a strong magnetic field is applied to the ring to align the magnetic domains in the radial direction. This step ensures that the magnet exhibits the desired magnetic properties.

3. Applications

NeFeB Radial Ring Magnets in High-Performance Electric Motors

NeFeB radial ring magnets are crucial components in high-performance electric motors, particularly in electric vehicles (EVs) and industrial automation systems. Their unique radial magnetization pattern allows for a more efficient magnetic flux distribution, enhancing torque density and overall motor performance. This design significantly reduces cogging torque, leading to smoother and more precise motor operation, which is essential for EVs’ acceleration and handling.

In high-performance electric motors, NeFeB radial ring magnets contribute to increased power output without compromising on compactness or weight, making them ideal for modern automotive designs. Their high energy product and superior magnetic strength enable motors to achieve higher efficiency, extending battery life and driving range in electric vehicles. Additionally, these magnets maintain stability under high temperatures, ensuring consistent performance in demanding environments.

4. Challenges and Innovations

4.1 Material Brittleness

One of the primary challenges associated with NdFeB magnets is their brittleness, which makes them prone to chipping and cracking during manufacturing and use. To address this issue, protective coatings and advanced machining techniques are employed.

4.2 Simulation-Driven Design

The design of radial ring magnets often involves complex simulations to predict magnetic field behavior and optimize geometries. Techniques such as finite element analysis (FEA) and radial basis function (RBF) modeling are used to achieve high precision and performance.

4.3 Sustainability

The production of NdFeB magnets relies on rare-earth elements, which are subject to supply chain constraints and environmental concerns. To address these challenges, researchers are exploring methods for recycling rare-earth elements from end-of-life magnets and developing alternative materials with similar properties.

4.4 Innovations in Manufacturing

Recent advancements in manufacturing techniques, such as AI-driven simulations and active learning frameworks, are enabling the production of more efficient and cost-effective radial ring magnets. For example, the NeRF-DA framework is being used to optimize the design and manufacturing processes of these magnets.

5. Conclusion

NdFeB Radial Ring magnets represent a fusion of advanced material science and precision engineering. Their unique radial orientation and superior magnetic properties make them indispensable in modern technologies, ranging from electric vehicles and wind turbines to quantum devices and optical systems.

As manufacturing techniques continue to evolve—driven by innovations in simulation, AI, and sustainability—these magnets will play an increasingly important role in shaping the future of technology. By addressing challenges such as material brittleness and supply chain constraints, researchers and manufacturers are paving the way for the next generation of high-performance radial ring magnets.

For further details on specific products or patents, refer to sources from Magengine, Ningbo Jinji, and academic studies on radial rolling processes.