Introduction

Neodymium magnets, also known as NdFeB or neo magnets, are among the strongest types of permanent magnets available today. Their extraordinary strength and versatility have made them indispensable in a variety of industries, from electronics and automotive to medical devices and renewable energy. However, this impressive power comes with a set of challenges. Improper handling and storage can not only reduce their effectiveness but also pose significant safety risks. This article delves into the essential guidelines for safely handling and storing neodymium permanent magnets, ensuring both optimal performance and safety.

Understanding Neodymium Magnets

Neodymium magnets are composed of an alloy of neodymium, iron, and boron (NdFeB), which gives them their remarkable magnetic properties. These magnets are part of the rare earth magnet family and are known for their high remanence (the ability to retain significant magnetization) and coercivity (resistance to demagnetization). Compared to other types of magnets, such as ferrite or alnico, neodymium magnets are significantly stronger, making them a popular choice in applications where powerful magnetic fields are required in compact spaces.

Common uses of neodymium magnets include computer hard drives, wind turbine generators, electric motors, and magnetic resonance imaging (MRI) machines. Their strength allows them to perform critical functions in these devices, from data storage to energy generation. However, their potency also requires careful handling and storage to prevent accidents and ensure long-term usability.

Safety Precautions When Handling Neodymium Magnets

Handling neodymium magnets requires strict adherence to safety protocols to prevent injury. Here are some key precautions:

1.Personal Protective Equipment (PPE): Always wear gloves when handling neodymium magnets to protect your hands from pinching injuries. Safety goggles are also recommended to shield your eyes from potential flying debris if the magnets snap together unexpectedly.

2. Safe Handling Practices: Neodymium magnets are incredibly strong and can snap together with great force, potentially causing injuries. To handle them safely, always keep larger magnets separated using spacers or keepers, and avoid placing body parts between them. Use a firm grip and controlled movements to minimize the risk of sudden magnet collisions.

3. First Aid Measures: In the event of an injury, such as pinched skin or minor cuts, clean the wound thoroughly and apply antiseptic. Seek medical attention for more severe injuries, especially if fingers or other body parts are trapped between strong magnets.

Environmental Considerations

Neodymium magnets are sensitive to their environment. To maintain their strength and longevity, it’s important to store them under ideal conditions:

1. Humidity and Temperature: Neodymium magnets should be stored in a dry environment with low humidity to prevent corrosion. Ideally, they should be kept at room temperature, as extreme temperatures can affect their magnetic properties. High temperatures, in particular, can cause demagnetization.

2. Corrosion Prevention: Although many neodymium magnets are coated with protective layers (such as nickel, zinc, or epoxy), they are still susceptible to rust if exposed to moisture. Using silica gel packets in storage containers can help control humidity levels and protect the magnets from corrosion.

Storage Solutions for Neodymium Magnets

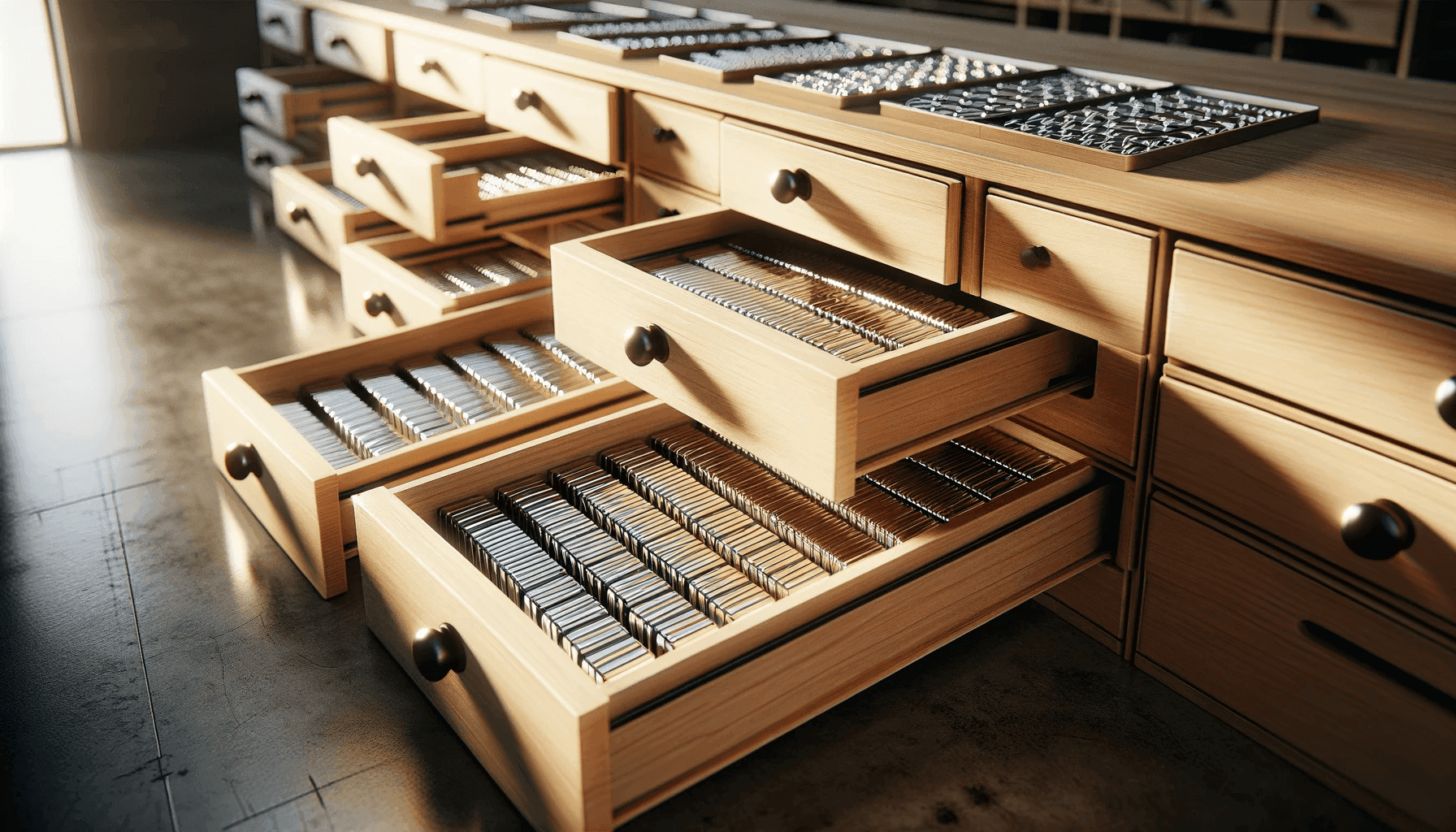

Proper storage of neodymium magnets is crucial to maintaining their performance and ensuring safety. Here are some effective storage solutions:

1. Storage Methods: Use non-magnetic containers to store neodymium magnets. Plastic or wooden boxes are ideal as they do not interfere with the magnetic fields. For smaller magnets, individual compartments within the container can prevent them from attracting each other.

2. Use of Spacers and Keepers: Spacers are materials placed between magnets to keep them apart, reducing the risk of accidental collisions. Keepers, often made of soft iron, are used to bridge the poles of magnets, reducing the external magnetic field and making the magnets safer to handle.

3. Organizational Tips: Labeling storage containers with the magnet size, shape, and strength can help in organizing and quickly locating the required magnets. Additionally, keeping an inventory log can assist in tracking the usage and storage of your magnet collection.

Transporting Neodymium Magnets

Transporting neodymium magnets requires special precautions to ensure safety during transit:

1. Packaging Guidelines: Use sturdy, non-magnetic materials for packaging. Ensure that magnets are separated using spacers or packed individually to prevent them from attracting each other during transport. Cushioning materials, such as foam or bubble wrap, can absorb shocks and protect the magnets from impacts.

2. Legal Regulations: Be aware of shipping restrictions and regulations concerning powerful magnets. Many shipping companies have specific guidelines for the transport of magnetic materials, which must be followed to prevent delays or legal issues.

3. Safety Measures: Clearly label packages containing magnets with appropriate warnings to inform handlers of the magnetic contents. This helps in taking necessary precautions during loading and unloading, ensuring the safety of personnel and equipment.

Disposal and Recycling

Proper disposal and recycling of neodymium magnets are important to minimize environmental impact:

1. Safe Disposal Practices: Do not dispose of neodymium magnets in regular trash, as they can cause damage to waste processing equipment and pose safety risks. Instead, follow local regulations for the disposal of magnetic materials.

2. Recycling Options: Many recycling centers accept neodymium magnets, allowing for the recovery of valuable rare earth materials. Recycling not only helps conserve resources but also reduces the environmental footprint of magnet production.

3. Environmental Benefits: Recycling neodymium magnets reduces the need for new mining and processing of rare earth elements, which can have significant environmental impacts. By recycling, you contribute to a more sustainable use of these critical materials.

Common Mistakes to Avoid

Avoiding common mistakes in handling and storing neodymium magnets can prolong their lifespan and ensure safety:

1. Handling Errors: One frequent mistake is using excessive force when separating magnets, which can lead to breakage or injury. Instead, use a sliding motion to gently pull them apart.

2. Storage Mistakes: Storing magnets in close proximity without proper spacers or keepers can result in unwanted magnetic interference and potential damage. Always use appropriate separation techniques to prevent this.

3. Real-life Examples: In one case, a manufacturer experienced significant delays and equipment damage due to improper magnet storage, leading to costly repairs and downtime. Learning from such examples can help avoid similar issues in your own operations.

Expert Tips and Best Practices

Industry professionals offer valuable insights into handling and storing neodymium magnets:

1. Professional Advice: Experts recommend conducting regular inspections of stored magnets to check for signs of corrosion or damage. This proactive approach can help identify issues early and prevent further degradation.

2. Innovative Solutions: Using magnetic shields or enclosures can help manage the magnetic field and enhance safety during handling and storage. These solutions are particularly useful in environments with sensitive electronic equipment.

3. Future Trends: Advances in magnet technology and storage solutions continue to evolve. Staying informed about the latest trends and innovations can help you adopt best practices and maintain the highest standards of safety and efficiency.

Conclusion

Proper handling and storage of neodymium permanent magnets are essential to maximizing their benefits and ensuring safety. By following the guidelines outlined in this article, you can effectively manage these powerful magnets and avoid common pitfalls. Remember, safety first – taking the necessary precautions not only protects you and your team but also preserves the integrity and performance of your neodymium magnets. Embrace these best practices and enjoy the many advantages that these extraordinary magnets have to offer.