Introduction: Humanoid Robots Are Leaving the Lab

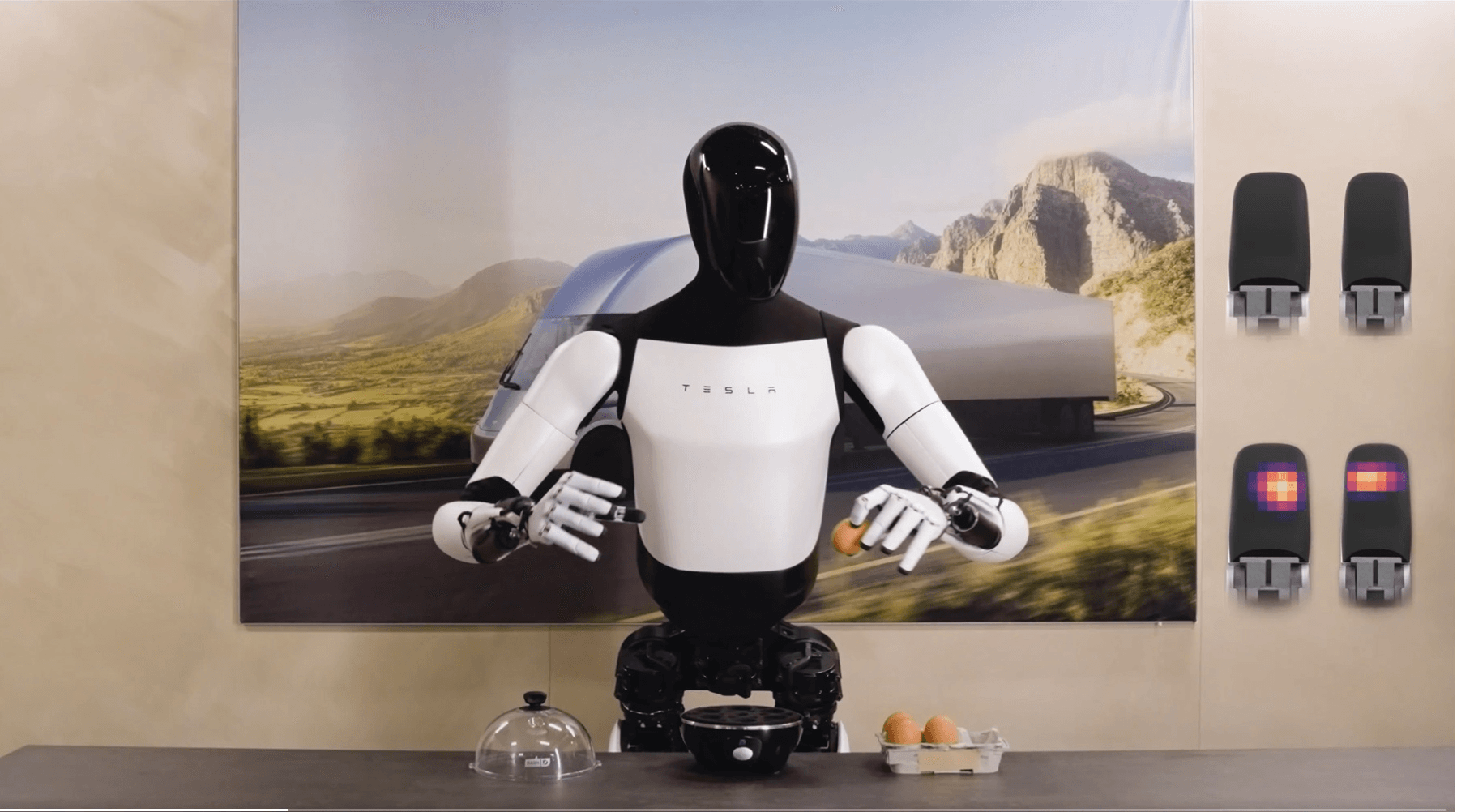

Humanoid robots have rapidly transitioned from research prototypes to pre-production systems poised for commercial deployment. Companies such as Tesla (Optimus), Figure AI, Agility Robotics, and several fast-moving Chinese robotics startups are no longer asking whether humanoid robots will be built at scale, but how to manufacture them reliably, economically, and with consistent performance.

While public attention often focuses on artificial intelligence, perception algorithms, and large language models, the physical reality of humanoid robots tells a different story. At the core of every joint, limb, and actuator lies a tightly integrated electromechanical system—servo motors, reducers, sensors, and magnetic components—that must function flawlessly over millions of cycles.

As the industry approaches mass production, an increasingly important question emerges:

Will magnetic components—often treated as “commodities”—become a critical bottleneck in humanoid robot manufacturing?

This article examines that question through the lens of servo motors and magnetic encoders, the two magnetic subsystems most essential to humanoid robot performance, reliability, and scalability.

1. The Mechanical Reality of a Humanoid Robot

A humanoid robot typically contains 30–60 actively controlled joints, depending on design complexity. Each joint must deliver:

- High torque density

- Fast response

- High positioning accuracy

- Low backlash and compliance

- Quiet, smooth motion

- Long operational life

To achieve this, most humanoid robots rely on servo actuator modules, each integrating:

- A high-performance electric motor

- A precision reducer (harmonic drive, planetary gearbox, or cycloidal reducer)

- A position feedback system (encoder)

- Power electronics and thermal management

Magnetic components are embedded in every one of these subsystems, yet they rarely receive the same level of attention as software or control algorithms.

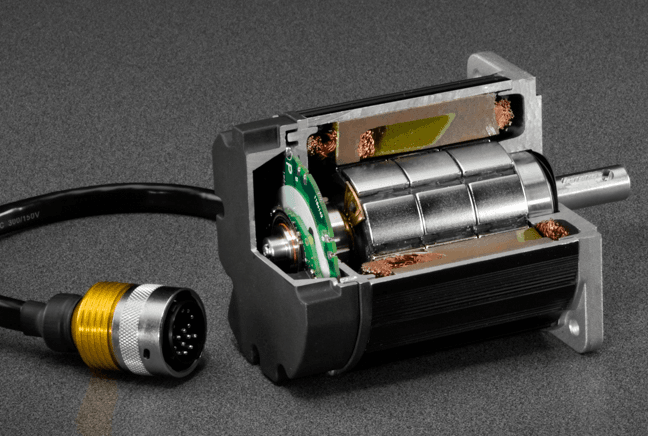

2. Servo Motors: The Magnetic Heart of Motion

2.1 Why Servo Motors Are Central to Humanoid Robots

Unlike industrial robots fixed to factory floors, humanoid robots must operate in human environments. This requires motors that are:

- Compact and lightweight

- Capable of frequent start-stop cycles

- Efficient at low and medium speeds

- Resistant to demagnetization and thermal drift

Permanent magnet synchronous motors (PMSMs), particularly those using NdFeB permanent magnets, have become the dominant choice.

2.2 Torque Density and Magnet Performance

Torque density is one of the most critical parameters for humanoid robots. Higher torque density allows:

- Smaller joints

- Lower overall robot weight

- Reduced energy consumption

This directly depends on magnet material properties, including:

- Remanence (Br)

- Coercivity (Hcj)

- Temperature stability

- Magnetization uniformity

As humanoid robots push toward more compact joints—especially in shoulders, hips, wrists, and ankles—the margin for magnet performance variation shrinks dramatically.

3. Why “Standard” Magnets Are No Longer Enough

In early prototypes, many robotics teams relied on off-the-shelf motor magnets. This approach works at low volumes but breaks down during scale-up.

3.1 Challenges Emerging at Scale

As production volumes increase, manufacturers encounter issues such as:

- Inconsistent torque output between motors

- Increased cogging torque

- Audible noise and vibration

- Thermal demagnetization under continuous load

- Reduced motor efficiency

These problems are often traced back not to motor design, but to magnet variability.

3.2 Custom Magnet Geometry Becomes Mandatory

Humanoid robot motors increasingly require:

- Arc-shaped magnets with tight dimensional tolerances

- Thin segmented magnets to reduce eddy current losses

- Multi-pole magnetization optimized for specific slot/pole combinations

This pushes magnet suppliers beyond simple material supply into engineering-driven customization.

4. Reducers and Magnetic Encoders: Precision Is Non-Negotiable

4.1 Why Encoders Matter More Than Ever

High-precision motion control is impossible without accurate feedback. In humanoid robots, encoders must deliver:

- Absolute position data

- High resolution

- Minimal latency

- Robustness against dust, oil, vibration, and shock

While optical encoders have long dominated precision motion control, magnetic encoders are rapidly gaining traction in humanoid robotics.

5. Magnetic Encoders vs Optical Encoders in Humanoid Robots

5.1 Why Magnetic Encoders Are Attractive

Magnetic encoders offer several advantages:

- Compact form factor

- Immunity to dust and grease

- Lower cost at scale

- High shock and vibration resistance

For humanoid robots operating in real-world environments, these advantages are decisive.

5.2 The Hidden Complexity of Magnetic Encoder Rings

Despite their apparent simplicity, magnetic encoder rings are among the most demanding magnetic components in a humanoid robot.

Critical requirements include:

- Extremely uniform pole spacing

- Stable magnetization over temperature

- Low harmonic distortion

- Tight concentricity with the mechanical axis

Any deviation directly degrades positioning accuracy, leading to control instability and cumulative motion error.

6. Reducers: Where Mechanical Precision Meets Magnetic Accuracy

Most humanoid robots use high-ratio reducers to amplify motor torque. The output position is often measured after the reducer, placing the encoder ring directly on:

- The harmonic drive flexspline

- The cycloidal output shaft

- The planetary carrier

In these locations, magnetic components must survive:

- High mechanical stress

- Micro-vibrations

- Temperature gradients

- Long-term fatigue

This makes material selection, coating, bonding method, and magnetization process critical.

7. The Supply Chain Reality: Where Bottlenecks Appear

7.1 Volume Is Not the Only Challenge

Many robotics teams assume that scaling magnet supply is merely a matter of increasing volume. In reality, the bottleneck lies in:

- Engineering capacity for custom magnet design

- Magnetization tooling and process repeatability

- Quality control for pole accuracy and consistency

A supplier capable of producing high-grade NdFeB magnets is not necessarily capable of producing robot-grade magnetic components.

7.2 Yield Losses Increase Rapidly

As tolerances tighten, yield losses during:

- Grinding

- Coating

- Magnetization

- Inspection

can increase dramatically. This impacts both cost and lead time, creating hidden risks in mass production planning.

8. Case Study Signals from the Industry (Public Information Only)

Although detailed supply chains remain confidential, several public signals suggest that magnetic components are already under scrutiny:

- Tesla has emphasized vertical integration and custom motor development for Optimus

- Figure AI has highlighted actuator innovation as a key differentiator

- Chinese humanoid robot startups increasingly advertise in-house actuator design

These trends suggest a growing recognition that actuator and magnetic subsystem control is strategic, not auxiliary.

9. Rare Earth Dependency and Strategic Risk

9.1 NdFeB Remains Dominant—but Vulnerable

High-performance NdFeB magnets remain unmatched in torque density. However, concerns include:

- Rare earth supply concentration

- Price volatility

- Export controls

Humanoid robots, requiring large quantities of precision magnets, amplify these risks.

9.2 Engineering Mitigation Strategies

Rather than replacing NdFeB entirely, manufacturers are pursuing:

- Magnet volume optimization through better magnetic circuit design

- Higher-grade magnets with smaller form factors

- Hybrid designs combining magnetic and mechanical optimization

This again increases reliance on custom magnetic engineering, not commodity supply.

10. Will Magnetic Components Become the Bottleneck?

10.1 Short Answer: Potentially, Yes

Magnetic components may not be the first bottleneck, but they are likely to become one as humanoid robots move from hundreds to tens of thousands of units.

Key reasons include:

- Limited number of suppliers capable of robot-grade magnetic precision

- Long development cycles for custom magnetization tooling

- Tight coupling between magnet performance and system-level control

10.2 The Real Bottleneck Is Engineering, Not Material

The true constraint is not rare earth availability alone, but engineering integration capability:

- Understanding motor, reducer, and encoder requirements as a system

- Translating control needs into magnetic specifications

- Maintaining consistency across large production volumes

11. Implications for Humanoid Robot Manufacturers

To avoid magnetic bottlenecks, leading manufacturers are beginning to:

- Involve magnetic component suppliers early in actuator design

- Co-develop custom magnet geometries and magnetization patterns

- Establish long-term supply partnerships rather than spot purchasing

- Treat magnetic components as strategic parts, not consumables

This mirrors the evolution seen previously in automotive electric motors and aerospace actuators.

12. Implications for Magnetic Component Suppliers

For suppliers, humanoid robotics represents both an opportunity and a challenge:

- Demand for high-precision, custom magnetic components will grow

- Quality expectations will approach aerospace standards

- Engineering support will matter as much as manufacturing capacity

Suppliers that remain focused solely on standard magnet products may struggle to participate meaningfully in this market.

Conclusion: Magnetic Components Will Shape the Humanoid Era

As humanoid robots approach mass production, attention is shifting from what robots can do to how reliably and efficiently they can be built.

In this transition, magnetic components—servo motor magnets and magnetic encoder rings in particular—are emerging as critical enablers. They sit at the intersection of materials science, mechanical engineering, and control systems, and their performance directly determines motion quality, energy efficiency, and system stability.

Whether magnetic components become a bottleneck depends not on scarcity alone, but on how early manufacturers recognize their strategic importance.

In the humanoid robot race, the quiet precision of magnets may prove just as decisive as the intelligence of software.

Related Products

Magnetic Encoder Rings