Electricity is the lifeblood of modern society, powering everything from the tiniest gadgets to massive industrial complexes. But have you ever wondered about the diverse methods through which this indispensable resource is generated? Among the many innovations in energy generation, the Permanent Magnet Generator (PMG) stands out as a fascinating technology. The concept of using permanent magnets to generate electricity might sound like magic, but it’s grounded in solid scientific principles and practical engineering. Let’s dive deep into the world of PMGs, explore how they work, and uncover their advantages and applications.

What is a Permanent Magnet Generator?

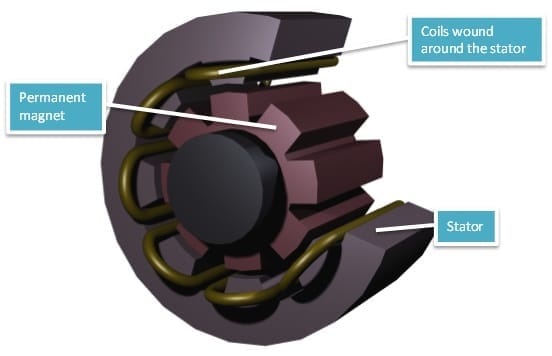

A Permanent Magnet Generator is a type of generator that utilizes permanent magnets to create the magnetic field necessary for electricity generation. Unlike traditional generators that rely on electromagnets powered by an external electrical source, PMGs employ magnets that maintain a constant magnetic field without needing additional power. This distinction makes PMGs highly efficient and reliable.

Components:

– Stator: The stationary part of the generator, typically consisting of coils of wire.

– Rotor: The rotating component that contains permanent magnets arranged in a specific pattern.

How it Works:

The basic working principle of a PMG revolves around electromagnetic induction. When the rotor spins, the permanent magnets move past the stator’s coils. This motion creates a change in the magnetic field, which induces an electric current in the coils according to Faraday’s law of electromagnetic induction. The generated electricity can then be harnessed for various applications.

Can a Permanent Magnet Generate Electricity?

The best idea for make permanent magnet generator / free energy 8000w (youtube.com)

Absolutely, a permanent magnet can generate electricity, but the process requires motion. The fundamental principle behind this is Faraday’s law of electromagnetic induction, which states that a change in the magnetic field within a closed loop induces an electromotive force (EMF). In simpler terms, moving a magnet near a coil of wire generates an electric current.

Mechanism:

– When a permanent magnet moves relative to a coil, the magnetic flux through the coil changes.

– This change in flux induces a voltage in the coil, causing current to flow if the circuit is closed.

– The faster the movement, the greater the change in magnetic flux and, consequently, the higher the generated voltage.

Efficiency:

PMGs are known for their high efficiency due to the lack of power losses associated with generating a magnetic field, as seen in traditional generators using electromagnets. This efficiency makes PMGs particularly suitable for applications where energy conservation is crucial.

Applications:

Permanent magnets are used in various small-scale generators, renewable energy systems like wind turbines, and industrial applications where consistent and reliable power is essential.

Advantages of Permanent Magnet Generators

Efficiency:

PMGs boast higher efficiency compared to traditional generators. The absence of field windings and the need for an external power source to create a magnetic field result in lower energy losses.

Durability:

With fewer moving parts and no need for brushes and commutators, PMGs experience less wear and tear, leading to longer operational life and reduced maintenance requirements.

Size and Weight:

PMGs are generally smaller and lighter than their traditional counterparts. This compact size makes them ideal for applications where space and weight are critical factors, such as in portable generators and electric vehicles.

Maintenance:

The simplicity of PMG design translates to lower maintenance needs. Without brushes that wear out and need replacement, the operational cost and downtime are significantly reduced.

Environmentally Friendly:

Since PMGs don’t require an external power source to maintain the magnetic field, they contribute to energy savings and reduced environmental impact.

Disadvantages of Permanent Magnet Generators

Cost:

The initial cost of PMGs can be higher due to the use of rare earth materials like neodymium in the magnets. These materials are expensive and can drive up the overall cost of the generator.

Temperature Sensitivity:

Permanent magnets can lose their magnetism at high temperatures, affecting the performance of PMGs in extreme conditions.

Demagnetization:

Over time, permanent magnets can gradually lose their magnetic properties, especially if subjected to physical shocks or high temperatures. This demagnetization can reduce the efficiency of the generator.

Fixed Field Strength:

The magnetic field strength in PMGs is constant and cannot be easily adjusted. This limitation makes them less flexible compared to generators using electromagnets, where the field strength can be controlled by varying the current.

Applications of Permanent Magnet Generators

Wind Turbines:

One of the most prominent applications of PMGs is in wind turbines. The efficiency and reliability of PMGs make them ideal for converting wind energy into electricity. Their compact size and low maintenance needs are significant advantages in remote or offshore installations.

Hydroelectric Power:

Small-scale hydroelectric generators often utilize PMGs due to their efficiency and ability to generate power with minimal maintenance. These generators can be found in micro-hydro setups where consistent and reliable power generation is crucial.

Electric Vehicles:

PMGs are integral to the automotive industry, especially in electric and hybrid vehicles. Their efficiency and compact size help in improving the overall performance and range of electric vehicles.

Portable Generators:

The lightweight and compact design of PMGs make them perfect for portable generators used in camping, outdoor activities, and emergency power supplies.

Industrial Applications:

PMGs find use in various industrial settings where reliable and efficient power generation is required. They are used in manufacturing processes, robotics, and other applications demanding high-performance generators.

Technological Advances in Permanent Magnet Generators

Material Science:

Advancements in magnet materials have significantly impacted the performance of PMGs. Research in developing stronger and more temperature-resistant magnets is ongoing, aiming to enhance efficiency and reduce costs.

Design Improvements:

Innovative designs in PMGs have led to better efficiency and reliability. Engineers are continually working on optimizing the arrangement of magnets and coils to maximize power output and minimize losses.

Integration with Renewable Energy Systems:

PMGs are increasingly being integrated with renewable energy systems. Their ability to efficiently convert mechanical energy into electrical energy makes them a perfect fit for wind and hydroelectric power systems.

Control Systems:

Modern electronic control systems have improved the performance management of PMGs. These systems allow for better regulation of the generated power and enhance the overall efficiency of the generator.

Future Prospects

Research and Development:

Ongoing research in PMG technology is focused on overcoming current limitations such as cost and temperature sensitivity. Innovations in materials and design are expected to drive the future development of more efficient and affordable PMGs.

Market Trends:

The demand for PMGs is expected to grow as industries and consumers seek more efficient and reliable power generation solutions. The renewable energy sector, in particular, is likely to see increased adoption of PMGs.

Sustainability:

PMGs have the potential to contribute significantly to a more sustainable energy future. Their high efficiency and low maintenance requirements make them an attractive option for various applications, reducing the overall environmental impact of power generation.

Challenges:

Despite their advantages, PMGs face challenges related to cost, material availability, and scalability. Addressing these challenges will be crucial for the widespread adoption of PMGs in the future.

Conclusion

Permanent Magnet Generators represent a significant advancement in the field of power generation. Their ability to generate electricity efficiently and reliably without the need for an external power source makes them a valuable technology in various applications. As research and development continue to improve PMG technology, we can expect to see even greater adoption and innovation in the future. Whether in renewable energy systems, electric vehicles, or industrial applications, PMGs hold the promise of a more efficient and sustainable energy future.