Introduction

Magnets play a pivotal role in numerous industries, from automotive and electronics to medical devices and industrial applications. Their utility is not just confined to the raw magnetic material itself but also to the various coatings that enhance their functionality and durability. Among these, plastic and rubber coatings are two of the most popular choices. But how do you know which is right for your specific needs? This article dives deep into the world of plastic-coated and rubber-coated magnets, helping you make an informed decision that suits your unique applications.

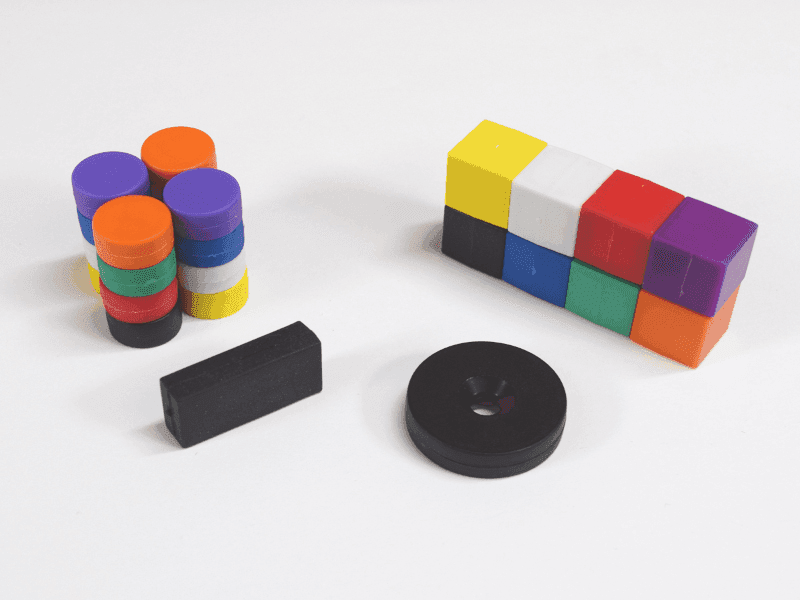

Understanding Magnet Coatings

Magnet coatings are essential for protecting magnets from corrosion, wear, and environmental damage. They also enhance magnetic performance by providing a smoother surface and reducing friction. Moreover, coatings can offer specific benefits tailored to particular applications, such as increased grip, flexibility, or chemical resistance.

Overview of Plastic-Coated Magnets

Plastic-coated magnets are created by encasing the magnetic material in a layer of plastic, typically using materials like ABS, PVC, or polyurethane. This coating serves multiple purposes: it protects the magnet from physical damage and corrosion, provides an aesthetic finish, and can be molded into various shapes and sizes to suit different applications.

Key Features and Benefits of Plastic Coatings:

Durability and Strength: Plastic coatings are known for their robust nature, offering excellent protection against mechanical damage and environmental wear.

Chemical Resistance: Plastics like ABS and PVC are resistant to many chemicals, making plastic-coated magnets suitable for harsh environments.

Versatility: Plastic coatings can be easily molded and colored, offering flexibility in design and application.

Applications of Plastic-Coated Magnets

Plastic-coated magnets find their use in a wide array of industries due to their durability and versatility.

Automotive Industry: Used in sensors and holding mechanisms, plastic-coated magnets withstand high temperatures and exposure to chemicals, ensuring long-lasting performance.

Consumer Electronics: These magnets are employed in securing components and housing mechanisms, providing a sleek and durable solution.

Medical Devices: In environments where non-reactive materials are crucial, plastic-coated magnets offer secure attachment without risking contamination or corrosion.

Pros and Cons of Plastic-Coated Magnets

Advantages:

Longevity and Durability: The plastic coating provides a protective barrier that extends the magnet’s lifespan.

Aesthetic Appeal: Available in various colors and finishes, plastic coatings can enhance the visual appeal of products.

Environmental Resistance: Resistant to moisture, chemicals, and extreme temperatures.

Disadvantages:

Potential for Brittleness: Over time, some plastic materials may become brittle, especially under prolonged exposure to UV light.

Higher Cost: The process of coating magnets with plastic can be more expensive than using uncoated magnets.

Limited Flexibility: Compared to rubber, plastic coatings offer less flexibility, which can be a drawback in applications requiring a high degree of adaptability.

Overview of Rubber-Coated Magnets

Rubber-coated magnets are encased in a layer of rubber, typically using materials such as EPDM or neoprene. This coating provides a flexible, durable, and grippy surface that protects the magnet from impact, moisture, and other environmental factors.

Key Features and Benefits of Rubber Coatings:

Flexibility and Grip: Rubber coatings offer excellent flexibility, making them ideal for applications requiring a non-slip surface.

Impact Resistance: Rubber absorbs shock, protecting the magnet from physical damage.

Waterproof Properties: Rubber-coated magnets are highly resistant to water and can be used in outdoor or damp environments.

Applications of Rubber-Coated Magnets

Rubber-coated magnets are favored in various applications due to their flexibility and durability.

Industrial Settings: Used in machinery mounting and vibration dampening, these magnets provide a secure, non-slip grip even in harsh conditions.

Outdoor Use: Ideal for waterproof applications and temporary fixtures, rubber-coated magnets perform well in challenging environments.

Sports and Recreation: Employed in sports gear and other recreational equipment, rubber-coated magnets offer secure attachment and durability.

Pros and Cons of Rubber-Coated Magnets

Advantages:

Excellent Grip and Flexibility: Rubber coatings provide a non-slip surface and can be easily molded into various shapes.

Superior Impact Resistance: The rubber layer absorbs shock, protecting the magnet from damage.

Weatherproof: Suitable for outdoor use due to their waterproof and weather-resistant properties.

Disadvantages:

Potential Degradation: Over time, exposure to certain chemicals or extreme conditions can cause the rubber to degrade.

Higher Initial Cost: Rubber coatings may have a higher initial cost compared to other types of coatings.

Aesthetic Limitations: While functional, rubber coatings are not as aesthetically versatile as plastic coatings.

Comparative Analysis

When choosing between plastic-coated and rubber-coated magnets, several factors should be considered:

Durability: Both coatings offer excellent protection, but plastic is generally more resistant to chemical exposure, while rubber excels in impact resistance.

Cost: Plastic-coated magnets tend to be less expensive in the long run due to their durability, while rubber-coated magnets might have a higher initial cost but offer better grip and flexibility.

Environmental Resistance: Plastic coatings resist chemicals and moisture well, while rubber coatings are better suited for wet or outdoor environments.

Flexibility and Grip: Rubber-coated magnets are superior in applications requiring a high degree of flexibility and a non-slip surface.

Specific Use Cases: The choice depends on the specific application requirements, such as environmental conditions, mechanical stress, and aesthetic considerations.

Choosing the Right Magnet for Your Needs

Selecting the right coated magnet involves understanding your specific application requirements and considering factors such as:

Application Environment: Determine whether the magnet will be exposed to harsh chemicals, moisture, or physical impact.

Performance Requirements: Consider the level of durability, flexibility, and grip needed.

Budget Constraints: Balance the initial cost against long-term durability and performance.

Decision-Making Flowchart:

Identify the Environment: Is the application indoors or outdoors? Will it be exposed to chemicals or physical impact?

Assess Performance Needs: Do you need flexibility and grip, or is chemical resistance more important?

Evaluate Cost: Consider both the initial cost and long-term durability.

Case Studies and Real-World Examples

Case Study 1: Automotive Industry

Situation: An automotive manufacturer needed durable magnets for sensor applications.

Solution: Plastic-coated magnets were chosen for their resistance to high temperatures and chemicals.

Outcome: The magnets provided reliable performance, leading to reduced maintenance costs and improved product longevity.

Case Study 2: Outdoor Sports Equipment

Situation: A sports equipment manufacturer required magnets for secure attachments in outdoor gear.

Solution: Rubber-coated magnets were selected for their superior grip and weatherproof properties.

Outcome: The equipment performed excellently in various weather conditions, earning positive feedback from users.

User Testimonials:

Automotive Manufacturer: “The plastic-coated magnets from MagnetsTek have been a game-changer for our sensors. Their durability and resistance to harsh environments have significantly improved our product reliability.”

Sports Equipment Designer: “Rubber-coated magnets provided the perfect solution for our outdoor gear. Their grip and flexibility ensure that our products stay secure, even in extreme conditions.”

Conclusion

Choosing the right magnet coating is crucial for ensuring optimal performance and longevity in your specific applications. Plastic-coated magnets offer durability and chemical resistance, making them ideal for harsh environments and aesthetically demanding applications. On the other hand, rubber-coated magnets provide superior flexibility, grip, and impact resistance, making them perfect for outdoor and industrial uses.

By understanding the strengths and weaknesses of each coating, you can make an informed decision that meets your needs. For expert advice and custom solutions, contact MagnetsTek. Our team is ready to help you choose the best magnets for your applications, ensuring top-notch performance and satisfaction.