Introduction

Magnets are indispensable components in modern engineering, powering everything from electric motors and medical devices to renewable energy systems and advanced sensors. While magnet material and grade often receive the most attention, pole orientation is another critical parameter that directly influences how a magnet interacts with its environment. Pole orientation refers to the direction in which a magnet is magnetized, defining the location and geometry of its north and south poles.

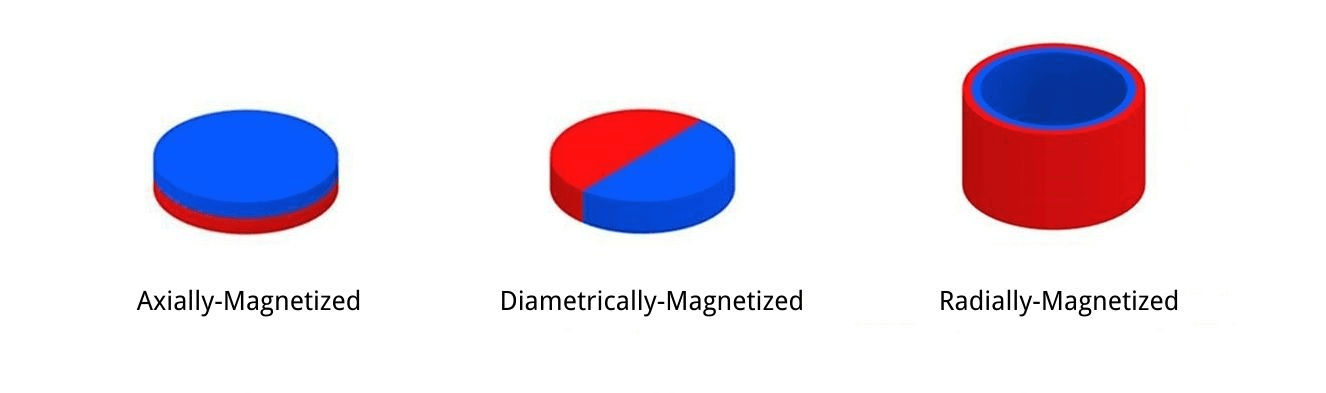

In custom magnet design, understanding the differences between axial, diametral, and radial magnetization is essential for achieving optimal performance. Each orientation produces unique magnetic field patterns, which in turn affect force, torque, alignment, and overall efficiency.

This article explores the three main pole orientation options—axial, diametral, and radial—with a focus on their engineering implications, advantages, limitations, and common applications.

What is Pole Orientation?

Pole orientation, sometimes referred to as magnetization direction, determines how magnetic domains are aligned within the magnet material during manufacturing. This alignment defines where the north and south poles appear and how the magnetic field is distributed around the magnet.

Key considerations include:

- Magnet geometry (disc, cylinder, ring, block, arc)

- Magnetizing method (pulsed field magnetization, fixture design)

- Application requirements (linear force, rotational torque, sensing field)

Without proper orientation, even a high-grade neodymium magnet may underperform in its intended application.

Overview of Pole Orientation Types

Pole orientation can generally be grouped into three categories for cylindrical and ring magnets:

- Axial Magnetization

- Poles located on flat faces of the magnet (top and bottom surfaces).

- Diametral Magnetization

- Poles located on opposite curved sides of the magnet.

- Radial Magnetization

- Poles distributed along the radius, either in multiple segments or continuously around the circumference.

Each configuration yields a distinct magnetic field profile and is suited to specific engineering uses.

Axial Magnetization

Definition

In axial magnetization, the magnet is magnetized along its central axis. The north pole appears on one flat face, and the south pole on the opposite face.

Example: A disc magnet magnetized axially has north on the top surface and south on the bottom surface.

Field Characteristics

- Strong axial field concentrated perpendicular to flat surfaces

- Field lines travel straight through the magnet’s thickness

- Limited lateral field around the circumference

Advantages

- Easy to manufacture and cost-effective

- Ideal for direct pull applications

- Common in standard off-the-shelf magnets

Limitations

- Limited field distribution around sides

- Not optimal for rotational or circumferential flux designs

Applications

- Holding and mounting systems (magnetic clamps, lifters)

- Magnetic therapy devices

- Axial flux motors (IEEE papers on axial flux design)

- Consumer electronics such as speakers and headphones

- Sensors requiring perpendicular detection

Diametral Magnetization

Definition

In diametral magnetization, the magnet is magnetized across its diameter. The north pole is located on one curved side, while the south pole is directly opposite on the other curved side.

Example: A cylinder magnet magnetized diametrally has poles on opposite rounded sides.

Field Characteristics

- Field flows horizontally across the diameter

- Strong lateral flux distribution

- Poles exposed along curved surfaces rather than flat ends

Advantages

- Provides strong sideways magnetic field

- Useful for rotation-based sensors

- Better coupling in certain mechanical assemblies

Limitations

- More complex and costly to manufacture

- Limited axial pull strength compared to axially magnetized magnets

Applications

- Rotary encoders and angular position sensors (Hall-effect sensor principle)

- Couplings and clutch mechanisms

- Magnetic stirring devices in laboratories

- Robotics requiring lateral detection

Radial Magnetization

Definition

In radial magnetization, the poles are distributed around the circumference of the magnet. This can be done in one of two ways:

- Segmented radial magnetization – alternating north and south poles around the perimeter.

- Continuous radial magnetization – north pole on the inner surface, south pole on the outer surface (or vice versa).

Example: A ring magnet radially magnetized may have north on its inner diameter and south on its outer diameter.

Field Characteristics

- Radial flux oriented from center outward (or inward)

- Uniform circumferential field distribution

- Can be designed with multiple poles (2, 4, 8, etc.)

Advantages

- Enables efficient torque generation in motors

- Provides balanced flux for rotary devices

- Customizable for pole count and application-specific patterns

Limitations

- Most complex and expensive to manufacture

- Requires specialized magnetizing fixtures

- Not widely available as standard stock items

Applications

- Brushless DC motors (BLDC) and permanent magnet synchronous motors (PMSM)

- High-efficiency generators (US DOE resources on energy efficiency)

- Wind turbine systems

- Automotive drive units and EV traction motors

- Precision robotics requiring smooth torque curves

Comparing Axial, Diametral, and Radial Magnetization

| Feature | Axial | Diametral | Radial |

|---|---|---|---|

| Field Direction | Through thickness (flat faces) | Across diameter (sides) | Outward/inward along radius |

| Poles Location | Top & bottom | Opposite curved sides | Inner vs. outer surface or multiple poles |

| Manufacturing Complexity | Low | Medium | High |

| Cost | Lowest | Moderate | Highest |

| Best For | Pull force, holding | Sensors, lateral flux | Motors, generators |

| Example Applications | Clamps, speakers | Rotary encoders | EV motors, wind turbines |

Engineering Considerations in Pole Orientation Selection

- Application Type

- Linear pull → Axial

- Rotational sensing → Diametral

- High-torque motors → Radial

- Integration with Components

- Shafts and housings may require radial or diametral poles

- Flat mounting surfaces favor axial

- Magnetic Flux Requirements

- Uniform field? Choose radial.

- Concentrated pull? Choose axial.

- Side detection? Choose diametral.

- Cost vs. Performance Trade-offs

- Radial offers performance advantages but raises cost.

- Axial remains cost-effective for general use.

- Temperature and Environment

- Pole orientation must withstand operating conditions, especially in EV and aerospace applications (NASA materials research).

Advanced Applications of Pole Orientation

Multi-Pole Radial Magnets

- EV traction motors use 8–16 pole radial magnets for high torque and smooth rotation.

Hybrid Assemblies

- Combining axial and radial orientations in a single device for specialized performance.

Miniaturized Diametral Magnets

- Used in MEMS sensors and biomedical devices for precise detection.

Cryogenic Applications

- Diametral magnets in low-temperature sensing instruments (Cryogenics journal).

Manufacturing Challenges

- Axial: Standard process, low challenge.

- Diametral: Requires specialized fixtures to align domains across the diameter.

- Radial: Needs custom magnetizing fixtures, often done post-assembly (especially for multipole ring magnets).

Additionally, tolerances, coating uniformity, and anisotropy alignment must be carefully controlled (ASM International materials standards).

Future Outlook

Pole orientation design is evolving alongside new technologies:

- Additive manufacturing of magnets may simplify complex orientations.

- High-temperature radial magnets are being developed for aerospace and EVs.

- Hybrid magnet systems combining permanent magnets with electromagnets may allow dynamic reorientation.

- Magnetic simulation software (FEA) is making custom pole design more accessible (COMSOL multiphysics examples).

Conclusion

Pole orientation—whether axial, diametral, or radial—is a fundamental design consideration in custom magnets. Each orientation produces distinct field characteristics and offers unique benefits for specific applications.

- Axial magnetization: simple, cost-effective, ideal for direct pull and holding.

- Diametral magnetization: provides lateral flux, essential for sensors and couplings.

- Radial magnetization: complex but powerful, enabling high-efficiency motors and generators.

At Magnetstek, we provide engineering support and manufacturing expertise to deliver custom neodymium magnets with the precise pole orientation needed for your application. Whether you require simple axial orientation or advanced multipole radial designs, our team ensures performance and reliability tailored to your project.

FAQ

Q1: Which pole orientation is best for motors?

Radial magnetization is typically best for motors due to its circumferential field distribution.

Q2: Can a disc magnet be diametrally magnetized?

Yes, though it is less common. The poles will appear on opposite curved edges instead of the flat faces.

Q3: Are radially magnetized magnets more expensive?

Yes, due to specialized fixtures and processes required for radial magnetization.

Q4: What orientation is most common in stock neodymium magnets?

Axial orientation is the most common and widely available.

Q5: Can one magnet have multiple orientations?

Yes. Advanced designs can feature multiple poles or hybrid orientations, though they require custom manufacturing.