Pot magnets, also known as magnetic holding devices or magnetic bases, are essential tools in various industrial applications. These powerful magnets are encapsulated in a metal pot, which enhances their magnetic strength and versatility. In this article, we will explore the diverse uses of pot magnets across different industries, their advantages, and factors to consider when selecting the right pot magnet for specific applications.

Understanding Pot Magnets

What Are Pot Magnets?

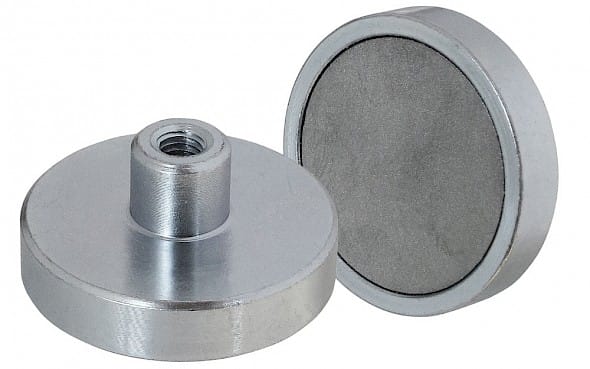

Pot magnets are composed of a magnet encased in a ferromagnetic pot or cup. This design amplifies the magnetic field and allows for a secure hold on various surfaces. Pot magnets come in various shapes, sizes, and strengths, making them suitable for a wide range of industrial uses.

How Pot Magnets Work

The fundamental principle behind pot magnets lies in magnetism. Pot magnets typically utilize neodymium (NdFeB) or ferrite materials, which generate strong magnetic fields. The pot’s metal casing directs and concentrates the magnetic field, allowing the pot magnet to hold ferromagnetic materials securely.

Types of Pot Magnets

Pot magnets can be categorized based on several criteria, including:

- Material Composition: Common materials include neodymium, ferrite, and samarium-cobalt.

- Coating: Pot magnets may have various coatings, such as nickel, zinc, or rubber, to enhance corrosion resistance and protect the magnet.

- Shape and Size: Available in cylindrical, disc, or rectangular forms, pot magnets can be customized based on application requirements.

Industrial Applications of Pot Magnets

Pot magnets find applications in numerous industries due to their unique properties and versatility. Here are some of the most notable uses across various sectors:

1. Manufacturing and Assembly

In manufacturing settings, pot magnets are used for holding workpieces in place during assembly and machining processes. Their strong holding force ensures stability, enhancing productivity and precision. Applications include:

- CNC Machining: Pot magnets hold components securely on machining tables, preventing movement during operations.

- Assembly Lines: They facilitate the assembly of parts by keeping them fixed in position.

2. Construction

In the construction industry, pot magnets are invaluable for lifting and securing heavy materials. Their ability to hold objects securely makes them ideal for:

- Steel Fabrication: Pot magnets can hold steel plates and beams in position during welding and cutting processes.

- Panel Installation: They assist in positioning metal panels and cladding on building exteriors.

3. Electronics

Pot magnets play a crucial role in the electronics sector, particularly in the production and assembly of electronic devices. Their applications include:

- Component Placement: They secure small electronic components on circuit boards during assembly.

- Testing and Prototyping: Pot magnets hold prototypes in place for testing and evaluation.

4. Automotive Industry

The automotive sector utilizes pot magnets for various purposes, including:

- Parts Holding: Pot magnets hold parts during the assembly process, ensuring proper alignment and stability.

- Testing and Inspection: They secure components in place during quality checks and inspections.

5. Robotics

In robotics, pot magnets serve as effective tools for gripping and holding components during various operations. Their ability to provide a strong hold makes them ideal for:

- Grippers: Pot magnets are often incorporated into robotic grippers for precise handling of metal parts.

- Positioning: They help position robotic arms during assembly tasks.

6. Packaging

In the packaging industry, pot magnets assist in securing packaging materials and components, ensuring efficient operations. Applications include:

- Labeling: Pot magnets hold labels in place during application.

- Product Positioning: They assist in positioning products on conveyor belts.

7. Medical Devices

In the medical field, pot magnets are used in various applications, such as:

- Holding Surgical Instruments: Pot magnets can hold surgical instruments in place during procedures, enhancing efficiency.

- Medical Device Assembly: They secure components during the assembly of medical devices.

8. Transportation

Pot magnets are employed in the transportation sector for applications such as:

- Railway Systems: They secure components on trains and ensure stability during transit.

- Cargo Handling: Pot magnets assist in lifting and securing cargo during loading and unloading processes.

Advantages of Pot Magnets

Pot magnets offer several advantages that make them a preferred choice in various industrial applications:

1. High Holding Force

One of the most significant benefits of pot magnets is their high holding force. The metal pot concentrates the magnetic field, resulting in a powerful grip on ferromagnetic materials. This makes them suitable for holding heavy objects securely.

2. Versatility

Pot magnets are versatile tools that can be used in diverse applications across various industries. Their adaptability makes them a valuable addition to any workspace.

3. Easy to Use

Pot magnets are user-friendly and require minimal setup. They can be easily placed and removed, allowing for quick changes in operations.

4. Durability

Most pot magnets are designed to withstand harsh industrial environments. They are resistant to wear and tear, ensuring long-lasting performance.

5. Cost-Effectiveness

Pot magnets are often more cost-effective than other holding devices. Their durability and reliability contribute to reduced downtime and maintenance costs.

6. Customization Options

Many manufacturers offer customizable pot magnets tailored to specific application requirements. This allows industries to select the ideal size, shape, and strength for their needs.

Factors to Consider When Choosing Pot Magnets

When selecting pot magnets for industrial applications, several factors should be considered to ensure optimal performance:

1. Holding Force Requirements

The holding force needed for a specific application is crucial. Ensure that the selected pot magnet can hold the intended weight securely.

2. Material Compatibility

Consider the materials being used in conjunction with pot magnets. They should be compatible with the magnet’s magnetic properties to ensure effective holding.

3. Environmental Conditions

Pot magnets may be exposed to various environmental conditions, such as humidity, temperature fluctuations, and corrosive substances. Selecting a magnet with appropriate coatings and materials can enhance durability.

4. Size and Shape

The size and shape of the pot magnet should match the application’s requirements. Evaluate the space available and the object being held to determine the appropriate dimensions.

5. Magnetic Field Direction

Understanding the magnetic field direction is essential for effective application. Ensure that the pot magnet is aligned correctly for optimal performance.

6. Safety Considerations

Consider safety factors, especially when using pot magnets in lifting applications. Ensure that they meet safety standards and guidelines for the specific industry.

Conclusion

Pot magnets have proven to be indispensable tools across various industrial applications. Their high holding force, versatility, and durability make them ideal for tasks ranging from assembly and construction to electronics and robotics. By understanding their features and advantages, industries can effectively leverage pot magnets to enhance productivity and efficiency in their operations. When selecting pot magnets, careful consideration of factors such as holding force, material compatibility, and environmental conditions will ensure optimal performance and safety.

As technology advances, the potential applications for pot magnets will continue to expand, solidifying their place as essential tools in modern industry. Whether in manufacturing, transportation, or medical devices, pot magnets will undoubtedly remain a key component in various industrial processes, driving innovation and efficiency.