Introduction: The Unsung Hero of Magnet Technology

Magnets are indispensable in numerous industries, from manufacturing and automotive to healthcare and consumer electronics. As industries evolve, so do the requirements for more durable and efficient materials. Among the innovations enhancing the performance of magnets, PTFE coating stands out as a significant development. This article explores the intricacies of PTFE-coated magnets, elucidating their importance, benefits, and applications across various sectors.

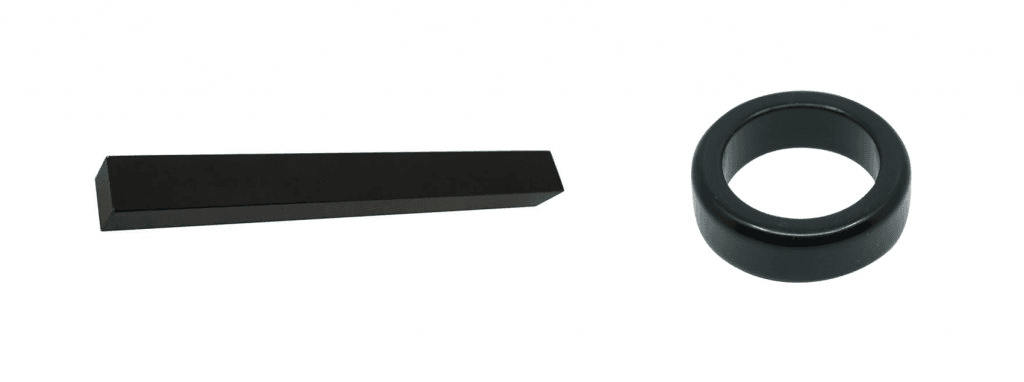

Understanding PTFE-Coated Magnets

What is PTFE?

Polytetrafluoroethylene (PTFE) is a high-performance polymer known for its remarkable properties, including non-stickiness, chemical resistance, and thermal stability. Originally discovered by accident in 1938, PTFE has found widespread applications, the most famous being its use in non-stick cookware. However, its unique characteristics make it an ideal material for coating magnets used in harsh environments.

Why Coat Magnets with PTFE?

Magnets, particularly those made from neodymium (NdFeB) and samarium cobalt (SmCo), are prone to corrosion and degradation when exposed to certain environments. PTFE coating serves as a protective barrier, preventing these magnets from interacting with elements that could compromise their integrity. This protective layer extends the lifespan of the magnets and maintains their magnetic properties.

The Science Behind PTFE Coating

Chemical Composition and Properties

PTFE is a polymer consisting of carbon and fluorine atoms. The strong carbon-fluorine bonds contribute to its high resistance to chemical reactions, making PTFE an inert material. This inertness is critical in applications where the magnet might be exposed to aggressive chemicals, such as in chemical processing or pharmaceutical industries.

Application Process

Applying PTFE to magnets involves a series of steps to ensure a uniform and durable coating. The process typically includes surface preparation, application of a primer, and finally, the PTFE coating. Surface preparation is crucial, as it ensures the magnet is clean and free of contaminants that could affect the adhesion of the PTFE layer. The coating is then cured at high temperatures to enhance its adhesion and durability.

Durability and Longevity

PTFE coatings are known for their durability, providing long-term protection even in extreme conditions. This longevity makes PTFE-coated magnets a cost-effective solution for industries where replacement and maintenance costs are significant concerns.

Advantages of PTFE-Coated Magnets

Corrosion Resistance

One of the most significant advantages of PTFE-coated magnets is their resistance to corrosion. Magnets used in environments with high humidity, saline conditions, or exposure to corrosive chemicals are at risk of deteriorating over time. PTFE coatings provide an impermeable barrier that protects the magnet’s surface from corrosion, thereby extending its functional life.

Chemical Resistance

PTFE’s chemical inertness makes it an excellent choice for magnets used in industries dealing with corrosive substances. For example, in the chemical processing industry, equipment and materials are frequently exposed to harsh chemicals that can corrode or degrade standard materials. PTFE-coated magnets resist such exposure, ensuring they maintain their performance and structural integrity.

Low Friction and Non-stick Properties

The low friction coefficient of PTFE is beneficial in applications where magnets interact with other surfaces. This property reduces wear and tear, not only on the magnet but also on adjacent components. In applications like magnetic couplings or bearings, the low friction and non-stick properties of PTFE are invaluable, as they enhance the efficiency and lifespan of the system.

Thermal Stability

PTFE remains stable across a wide temperature range, making it suitable for high-temperature applications. This thermal stability is particularly important in industries like automotive and aerospace, where materials are exposed to fluctuating and extreme temperatures. PTFE-coated magnets can operate efficiently in these conditions without degrading or losing their magnetic properties.

Electrical Insulation

While magnets are generally not conductive, PTFE coatings provide an additional layer of electrical insulation. This feature is particularly useful in electronic applications where unintentional electrical contact could cause malfunctions or damage to sensitive components.

Hygiene and Cleanability

In industries where hygiene is crucial, such as food processing or healthcare, the non-stick and easy-to-clean nature of PTFE-coated magnets is a significant advantage. These properties prevent the buildup of contaminants and facilitate easy cleaning, ensuring that the equipment remains sanitary.

Applications of PTFE-Coated Magnets

Chemical Processing

In the chemical processing industry, equipment often encounters corrosive chemicals that can degrade standard magnets. PTFE-coated magnets are resistant to such environments, providing durability and reliability. For example, in processes involving the mixing or separation of chemical compounds, PTFE-coated magnets can be used in magnetic stirrers and separators without the risk of corrosion.

Marine Applications

The marine environment is notoriously harsh on materials, with saltwater and humidity causing rapid corrosion. PTFE-coated magnets are ideal for use in such settings, providing resistance to these corrosive elements. They are commonly used in marine sensors, navigation equipment, and various underwater applications where durability and longevity are crucial.

Automotive Industry

The automotive sector utilizes magnets in various components, including sensors, electric motors, and actuators. PTFE-coated magnets are particularly valuable in under-the-hood applications where they are exposed to oils, chemicals, and high temperatures. The coating protects the magnets, ensuring consistent performance and extending their service life.

Food Processing

In the food industry, equipment hygiene is paramount. PTFE-coated magnets are used in food processing equipment, such as magnetic separators and conveyors, where they help prevent contamination and ensure easy cleaning. The non-stick properties of PTFE also prevent the buildup of food residues, which can harbor bacteria.

Medical Equipment

The biocompatibility and sterilizability of PTFE-coated magnets make them suitable for use in medical devices. They are used in MRI machines, surgical instruments, and various diagnostic equipment, where the coating provides protection against bodily fluids and sterilization processes.

Aerospace

In aerospace applications, materials must withstand extreme conditions, including high temperatures, radiation, and mechanical stress. PTFE-coated magnets are used in components such as sensors and actuators, where they provide reliable performance without adding significant weight. The coating’s resistance to radiation and thermal stability are particularly valuable in this industry.

Case Studies: Real-World Applications

Case Study 1: Chemical Processing Plant

A chemical processing plant faced issues with corrosion in its magnetic separation equipment, leading to frequent maintenance and replacement costs. By switching to PTFE-coated magnets, the plant significantly reduced these issues. The magnets demonstrated superior resistance to the harsh chemicals used in the process, resulting in longer equipment life and reduced downtime.

Case Study 2: Marine Navigation System

A marine navigation equipment manufacturer needed magnets that could withstand prolonged exposure to saltwater. The company opted for PTFE-coated magnets, which provided excellent corrosion resistance and maintained magnetic performance over time. This choice resulted in more reliable equipment and lower maintenance costs.

Case Study 3: Automotive Electric Motors

An automotive company required magnets for electric motors that could operate reliably in high-temperature environments. PTFE-coated neodymium magnets were chosen for their thermal stability and durability. The coating protected the magnets from the harsh conditions under the hood, resulting in motors that performed consistently and had a longer lifespan.

Customization Options: Neodymium and SmCo Magnets

Custom Neodymium Magnets

Neodymium magnets are known for their exceptional magnetic strength, making them suitable for a wide range of applications, from consumer electronics to industrial machinery. However, their susceptibility to corrosion necessitates protective measures like PTFE coating. At MagnetsTek, we offer Custom Neodymium Magnets with PTFE coatings, tailored to meet the specific needs of our clients. These magnets can be customized in terms of size, shape, and magnetic strength, ensuring they fit perfectly into your application.

Custom SmCo Magnets

Samarium cobalt (SmCo) magnets are prized for their stability at high temperatures and resistance to demagnetization. This makes them ideal for demanding applications, such as in aerospace and medical devices. However, like neodymium magnets, SmCo magnets can benefit from additional protection. Our Custom SmCo Magnets with PTFE coatings offer enhanced durability and corrosion resistance, ensuring optimal performance in even the harshest conditions.

The Future of PTFE-Coated Magnets

Advances in Coating Technology

As industries continue to evolve, so does the technology behind PTFE coatings. Future developments may include more advanced coatings that offer even greater resistance to corrosion, wear, and extreme temperatures. Research is ongoing into new fluoropolymer blends and application techniques that could enhance the performance characteristics of PTFE coatings.

Environmental Considerations

With growing environmental concerns, there is an increasing focus on developing sustainable materials and processes. PTFE coatings are no exception. Innovations may lead to eco-friendly coatings that offer the same level of performance but with a reduced environmental impact. This could include the development of biodegradable coatings or more efficient manufacturing processes that reduce waste.

Integration with Smart Technologies

The integration of magnets with smart technologies is an exciting frontier. PTFE-coated magnets could play a role in the development of sensors and actuators for IoT devices, smart appliances, and autonomous vehicles. As these technologies advance, the demand for durable, reliable, and high-performance magnets will continue to grow.

Conclusion: The Unsung Heroes of Industrial Magnets

PTFE-coated magnets may not always be in the spotlight, but their impact on various industries is undeniable. They offer a unique combination of corrosion resistance, chemical inertness, low friction, and thermal stability, making them an invaluable asset in many applications. From extending the life of magnets in harsh environments to enhancing their performance in high-temperature settings, PTFE coatings provide a range of benefits that standard magnets cannot match.

At MagnetsTek, we are committed to providing high-quality, custom magnet solutions that meet the unique needs of our clients. Our PTFE-coated magnets, including Custom Neodymium Magnets and Custom SmCo Magnets, are designed to perform in the most demanding environments, ensuring reliability and longevity. Whether you’re in the automotive, aerospace, chemical, or any other industry, our magnets can provide the performance and durability you need.

In conclusion, as industries continue to push the boundaries of technology and performance, the role of PTFE-coated magnets will only become more critical. They are indeed the unsung heroes of industrial magnets, providing solutions to complex challenges and enabling advancements across various fields. For those looking to optimize their systems and equipment, PTFE-coated magnets represent a wise and forward-thinking choice. Contact us today to learn more about how our custom magnet solutions can benefit your business and help you stay ahead in a competitive market.