Radial vs Axial Flux Motors: Which Is Suitable for the Future of Electric Machines?

Introduction

As the global demand for efficient, compact, and sustainable electric machines increases—especially in electric vehicles (EVs), drones, and renewable energy systems—engineers are exploring different motor topologies to optimize performance. Among these, radial flux motors (RFMs) and axial flux motors (AFMs) represent two competing designs with unique advantages and limitations.

This article provides an in-depth comparison between radial and axial flux motors, analyzing their working principles, performance characteristics, real-world applications, and future potential in electrified industries.

1. Understanding the Basics

1.1 What Is a Radial Flux Motor?

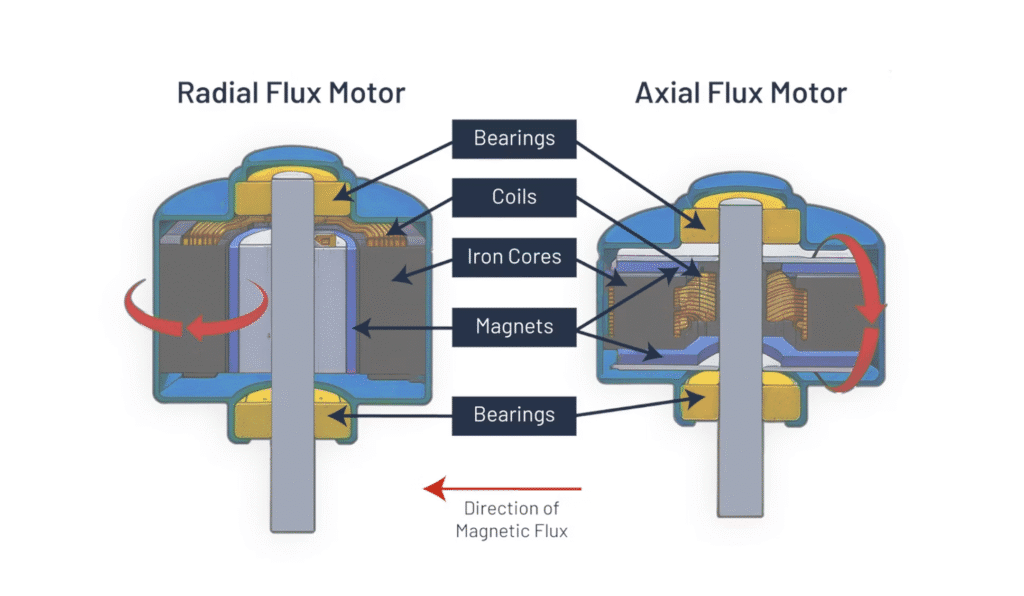

Radial flux motors are the most common type of electric motor. In these motors, the magnetic flux travels radially from the center of the rotor outward (or vice versa). The stator surrounds the rotor, and torque is produced by the interaction of the magnetic fields in the radial direction.

Key Characteristics:

- Well-established manufacturing ecosystem

- Cylindrical geometry

- Widely used in automotive, industrial, and appliance sectors

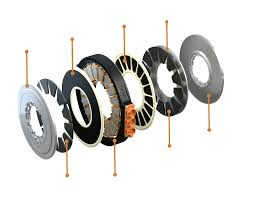

1.2 What Is an Axial Flux Motor?

Axial flux motors, also known as pancake motors, feature a different configuration. The magnetic flux travels parallel to the axis of rotation. The rotor and stator are placed face-to-face, forming a disk-like structure.

Key Characteristics:

- Flat and compact design

- High torque density

- Less common but gaining popularity

2. Design & Construction Differences

| Feature | Radial Flux Motor | Axial Flux Motor |

| Magnetic Flux Path | Radial | Axial (parallel to shaft) |

| Geometry | Cylindrical | Disc or pancake-like |

| Cooling Method | Often air or liquid-cooled from outer shell | Can be internally cooled through rotor plates |

| Windings | Typically distributed or concentrated | Often concentrated for compactness |

| Manufacturing Maturity | High | Still evolving |

3. Performance Comparison

3.1 Power and Torque Density

Axial Flux Motors generally provide higher torque density, especially in space-constrained applications.

Radial Flux Motors are more scalable for higher power applications due to better-established cooling and structural design methods.

3.2 Efficiency

AFMs can achieve greater efficiency due to shorter magnetic paths and lower copper losses.

RFMs, while slightly less efficient in compact applications, benefit from refined manufacturing processes and robust thermal management.

3.3 Cooling and Thermal Management

Radial motors often rely on outer casing for heat dissipation.

Axial motors offer greater flexibility with internal cooling options, enabling enhanced performance under thermal stress.

3.4 Maintenance and Reliability

RFMs have a long track record and are known for proven reliability.

AFMs require precise manufacturing tolerances, which may lead to higher costs and potential reliability concerns in mass production.

4. Application Suitability

| Application | Preferred Motor Type | Reason |

| Electric Vehicles (EVs) | Axial (for premium/compact EVs), Radial (mass-market EVs) | AFMs offer higher torque-to-weight, RFMs are cost-effective |

| Aerospace & Drones | Axial Flux | Lightweight and high power density |

| Industrial Drives | Radial Flux | Ruggedness, availability, and low cost |

| Robotics & Wearables | Axial Flux | Compactness and torque efficiency |

| Wind Turbines | Radial Flux (most) | Easier scalability and structural design |

| High-Performance Sports Cars | Axial Flux | Superior power-to-weight ratio |

5. Manufacturing and Scalability

Radial Flux:

- Benefits from decades of industrial experience

- Compatible with automated production lines

- Easier to source components

Axial Flux:

- Emerging ecosystem with limited manufacturers

- Requires high-precision assembly

- Still maturing in terms of global supply chain

6. Cost Analysis

- Short-term: RFMs are cheaper to produce due to mature tooling and high volume.

- Long-term: As AFMs reach mass production, their cost per kW could become competitive due to material savings (e.g., less copper and iron).

7. Environmental and Sustainability Impact

- AFMs require fewer raw materials, reducing environmental footprint.

- RFMs currently consume more resources but offer longer proven lifespans.

- The shift toward recyclable motor components may favor axial flux in the future.

8. Technological Trends & Innovations

8.1 Material Advances

- High-performance magnets (e.g., NdFeB) enhance both RFM and AFM designs.

- New stator winding methods are improving efficiency in axial flux motors.

8.2 Cooling Innovations

- Liquid cooling in AFMs is becoming standard in high-performance EVs.

- RFMs benefit from external jacket or oil-cooled housings.

8.3 Simulation and Digital Twin Tools

- Engineers now use multiphysics simulation to optimize both types for specific use cases.

- AI-driven motor design is accelerating axial flux motor development.

9. Industry Adoption: Who’s Using What?

| Company | Motor Type | Application Area |

| Tesla | Radial Flux | Model 3/Y drive motors |

| YASA (Mercedes-AMG) | Axial Flux | Electric sports cars |

| Lucid Motors | Radial Flux | Proprietary ultra-compact EV motors |

| Magnax | Axial Flux | Aerospace and premium EVs |

| Siemens | Radial Flux | Industrial motors and automation |

| Turntide | Switched Reluctance (RFM variation) | Commercial HVAC and transport |

10. Challenges Ahead

Axial Flux

- Scalability in manufacturing

- Supply chain for flat laminated cores

- Tolerance stack-up and bearing alignment

Radial Flux

- Lower torque density in compact designs

- Heavier systems

- Thermal management in high-performance scenarios

Conclusion: Which Motor Wins the Future?

There is no one-size-fits-all answer. The future likely belongs to a coexistence of both motor types:

- Radial flux motors will dominate in mass-market applications where cost, availability, and ruggedness matter most.

- Axial flux motors are ideal for cutting-edge applications where space, weight, and efficiency are premium considerations—like aerospace, performance EVs, and robotics.

As manufacturing techniques for axial flux motors improve and demand for lightweight high-efficiency systems grows, AFMs will likely gain more market share, particularly in premium and high-performance sectors.

Frequently Asked Questions (FAQs)

- Which is more efficient: radial or axial flux motors?

Axial flux motors tend to be more efficient in compact applications due to shorter magnetic paths and reduced losses. - Are axial flux motors commercially available?

Yes, but they are currently used more in specialized or premium products. Mainstream adoption is still growing. - What limits the widespread use of axial flux motors?

Challenges in manufacturing, precision requirements, and supply chain maturity. - Why are radial flux motors still dominant?

They benefit from decades of optimization, cost-effectiveness, and global production infrastructure. - Can axial flux motors replace radial flux motors in EVs?

In high-performance or space-limited designs, yes. But for general applications, radial flux still offers better scalability. - Do axial flux motors require special cooling?

Many use integrated liquid cooling due to compact designs and high power density. - What industries are driving axial flux development?

Aerospace, electric sports cars, robotics, and drones. - Are there hybrid motor designs?

Yes, some experimental motors combine radial and axial flux principles for niche applications. - Which is easier to manufacture?

Radial flux motors have simpler and more mature production lines. - Who are the leading axial flux motor manufacturers?

Companies like YASA, Magnax, and Saietta are leading the field.

2 Replies to “Radial vs Axial Flux Motors: Which Is Suitable for the Future of Electric Machines?”

Explain why motor torque depends on 3rd power of radius in Axial Flux & .

on 4th power of radius for conventional Radial Flux motors .

Thanks

Motor torque in axial flux designs scales with the cube of the radius because the torque is proportional to the electromagnetic shear stress times the active face area of the rotor (which scales with the square of the radius) times the lever arm (which adds another factor of radius), whereas in conventional radial flux designs, when scaled proportionally for similar magnetic loading and cooling, the active cylindrical surface area grows with the cube of the radius (circumference × axial length both increasing with radius) and the lever arm adds another factor of radius, making the torque scale with the fourth power of the radius.