Neodymium magnets, commonly referred to as NdFeB magnets or rare-earth magnets, are widely recognized for their extraordinary magnetic strength and versatility. These magnets have applications ranging from medical devices to electric motors, from household appliances to wind turbines. Despite their impressive magnetic properties, neodymium magnets are prone to corrosion and degradation, especially in harsh environments. Therefore, surface treatment is essential to extend their lifespan, maintain performance, and protect them from damage.

This article delves into the various surface treatments applied to neodymium magnets, examining the benefits, common techniques, and how they contribute to the overall durability of these powerful magnets.

Understanding the Composition and Vulnerabilities of Neodymium Magnets

Neodymium magnets are primarily composed of three key elements: neodymium (Nd), iron (Fe), and boron (B), combined to form an Nd₂Fe₁₄B structure. While this combination results in high magnetic strength, it also introduces some vulnerabilities. Iron, for example, is highly reactive to oxygen and moisture, making neodymium magnets prone to oxidation and rust.

Without appropriate surface treatment, exposure to air and moisture can cause the iron in the magnet to corrode. This corrosion not only weakens the structural integrity of the magnet but also leads to a reduction in magnetic performance over time. In fact, untreated neodymium magnets can become brittle and even crumble in humid environments.

Why Surface Treatment Is Crucial for Neodymium Magnets

Surface treatments are essential for neodymium magnets for several reasons:

- Corrosion Resistance: By applying a protective layer, the surface of the magnet is shielded from oxygen and moisture, preventing rust and oxidation.

- Enhanced Durability: Surface treatments improve the magnet’s mechanical strength, helping it withstand physical wear and tear.

- Improved Aesthetic Appeal: Some treatments provide a visually appealing finish, making the magnets suitable for use in consumer products where appearance is important.

- Prevention of Chipping and Cracking: Neodymium magnets are brittle by nature, and a surface treatment can prevent small chips or cracks from forming during handling or application.

- Electrical Isolation: In some applications, surface coatings help provide electrical insulation, preventing short circuits in electronic devices.

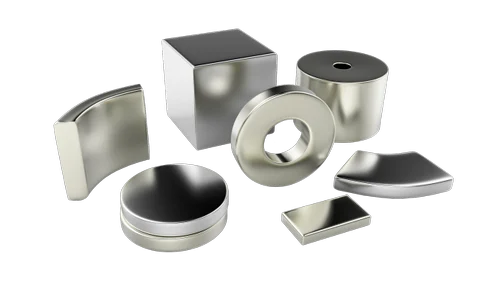

Common Surface Treatments for Neodymium Magnets

Several surface treatment methods are commonly used to enhance the properties of neodymium magnets. Each method offers distinct advantages depending on the specific application and environmental conditions in which the magnets will be used.

1. Nickel-Copper-Nickel (Ni-Cu-Ni) Coating

What It Is:

One of the most commonly used coatings for neodymium magnets is the nickel-copper-nickel (Ni-Cu-Ni) triple-layer coating. This process involves applying a layer of copper between two layers of nickel to create a corrosion-resistant and durable surface.

Benefits:

- Corrosion Resistance: The outer nickel layers protect against oxidation and moisture penetration.

- Enhanced Durability: Copper adds mechanical strength to the magnet, reducing the risk of cracking and chipping.

- Aesthetic Appeal: The shiny silver finish created by the nickel coating is visually attractive, making it ideal for consumer products.

Applications:

Ni-Cu-Ni coated magnets are commonly used in medical devices, motors, sensors, and consumer electronics.

2. Epoxy Resin Coating

What It Is:

Epoxy resin coating involves applying a layer of epoxy, a type of durable polymer, onto the surface of the magnet. This coating is known for its strong adhesive properties and resistance to chemicals and environmental degradation.

Benefits:

- Superior Corrosion Protection: Epoxy forms an airtight and moisture-proof seal around the magnet, offering excellent protection in high-humidity environments.

- Chemical Resistance: Epoxy is resistant to acids, alkalis, and other corrosive substances.

- Flexibility: This coating can be applied in various colors, allowing for aesthetic customization.

Applications:

Magnets coated with epoxy resin are widely used in outdoor applications, such as wind turbines, marine equipment, and sensors exposed to harsh environmental conditions.

3. Zinc (Zn) Coating

What It Is:

Zinc coating, also known as galvanization, is a process where a thin layer of zinc is applied to the surface of the magnet. This creates a sacrificial layer that oxidizes before the underlying iron in the magnet.

Benefits:

- Cost-Effective: Zinc is relatively inexpensive, making it a popular choice for budget-conscious applications.

- Good Corrosion Resistance: While not as effective as nickel or epoxy coatings, zinc still provides a decent level of corrosion protection.

- Matte Finish: Zinc coatings give magnets a matte grey appearance, which can be beneficial for certain industrial applications.

Applications:

Zinc-coated neodymium magnets are commonly used in automotive parts, industrial machinery, and construction materials.

4. Gold (Au) Coating

What It Is:

Gold coating is a premium surface treatment that involves applying a thin layer of gold onto the magnet. While more expensive than other coatings, gold offers some unique properties.

Benefits:

- Excellent Conductivity: Gold is an excellent conductor of electricity, making it ideal for electronic applications.

- Biocompatibility: Gold is non-toxic and biocompatible, meaning it can be safely used in medical devices and implants.

- Corrosion Resistance: Gold is highly resistant to oxidation, offering superior protection against rust and moisture.

Applications:

Due to its biocompatibility and conductivity, gold-coated neodymium magnets are often used in medical devices, jewelry, and sensitive electronic equipment.

5. Parylene Coating

What It Is:

Parylene is a type of polymer coating applied through vapor deposition. It forms an extremely thin, uniform layer around the magnet, offering excellent moisture and chemical resistance.

Benefits:

- Thin and Lightweight: Parylene coatings are incredibly thin, adding minimal weight or thickness to the magnet.

- High Corrosion Protection: Parylene creates an impenetrable barrier against moisture and corrosive chemicals.

- Biocompatibility: Parylene is often used in medical devices due to its non-reactive and biocompatible nature.

Applications:

Parylene-coated magnets are commonly used in sensitive medical and electronic applications where precise protection from moisture is required without adding bulk.

6. Phosphating

What It Is:

Phosphating is a process in which a phosphate coating is applied to the surface of the magnet. This treatment enhances adhesion for paints and other coatings.

Benefits:

- Enhanced Coating Adhesion: Phosphating improves the bonding between the magnet and other surface treatments, such as epoxy or paint.

- Mild Corrosion Resistance: Phosphates offer moderate protection against moisture and oxidation.

Applications:

Phosphating is typically used as a pre-treatment in the automotive industry, where magnets are coated with paint or epoxy for enhanced protection and aesthetics.

Factors to Consider When Choosing a Surface Treatment

The choice of surface treatment for neodymium magnets largely depends on the specific application and environmental conditions in which the magnet will be used. Here are some key factors to consider:

- Environmental Exposure: Magnets used in outdoor or high-humidity environments require stronger corrosion protection, such as epoxy resin or parylene coatings.

- Mechanical Stress: In applications where magnets are subjected to physical stress or wear, a durable coating like nickel or zinc may be necessary to prevent chipping or cracking.

- Chemical Exposure: For magnets used in chemically harsh environments, such as in laboratories or industrial settings, coatings that resist acids and alkalis, like epoxy or parylene, are ideal.

- Aesthetic Requirements: In consumer-facing products, the appearance of the magnet may be a factor. Nickel coatings provide a shiny, professional finish, while epoxy coatings offer flexibility in color.

- Cost Constraints: Surface treatments like gold and parylene are more expensive, while zinc and nickel are more cost-effective options. The choice will depend on the budget for the application.

- Electrical Conductivity: If the magnet will be used in electronic devices, coatings that offer electrical insulation, such as epoxy or parylene, may be necessary to prevent short circuits.

The Future of Surface Treatments for Neodymium Magnets

As technology continues to advance, new and improved surface treatments for neodymium magnets are being developed. Research into nanocoatings, for example, is showing promise in creating even thinner, more protective layers that enhance the performance and longevity of magnets. These coatings could offer unprecedented levels of corrosion resistance, durability, and electrical insulation while maintaining the magnet’s compact size and weight.

Moreover, environmentally friendly coatings are becoming more important as industries seek to reduce their environmental impact. Future surface treatments may focus on minimizing the use of toxic chemicals, opting for biodegradable or recyclable coating materials.

Conclusion

Neodymium magnets are among the most powerful and versatile magnets available today, but their susceptibility to corrosion and physical damage makes surface treatment an essential aspect of their production and application. From nickel-copper-nickel coatings to advanced epoxy resins, a wide range of surface treatments is available to enhance the durability, corrosion resistance, and overall performance of these magnets.

Understanding the specific needs of your application—whether it involves exposure to harsh environments, physical stress, or aesthetic considerations—will help you choose the right surface treatment. As technology continues to evolve, we can expect even more innovative and environmentally friendly surface treatments to emerge, further extending the lifespan and capabilities of neodymium magnets across industries.