In the world of materials science and engineering, rubber magnets often seem to be the unsung heroes of the magnetic materials family. Though they may not have the same spotlight as their metallic or ceramic counterparts, rubber magnets possess unique properties that make them indispensable in various applications. Imagine a material that combines the flexibility and versatility of rubber with the magnetic strength of traditional magnets—this is the essence of rubber magnets. Their ability to conform to different shapes, combined with their remarkable magnetic properties, opens up a realm of possibilities that stretch from everyday household items to advanced industrial applications. But, as with any material, rubber magnets come with their own set of advantages and limitations. In this article, we will delve deep into the world of rubber magnets, exploring their numerous benefits, potential drawbacks, and the balance between these factors that influence their usability in various domains.

The Advantages of Rubber Magnets

Versatility and Flexibility

One of the most notable advantages of rubber magnets is their exceptional flexibility. Unlike traditional rigid magnets, rubber magnets can be easily bent, twisted, and shaped to fit diverse applications. This inherent flexibility makes them ideal for use in a range of products, from promotional items and custom shapes to industrial components that require specific forms.

Lightweight and Easy to Handle

Rubber magnets are significantly lighter than metal or ceramic magnets, making them easier to handle and integrate into various designs. This lightweight nature is especially beneficial in applications where weight is a critical factor, such as in portable devices or lightweight assemblies. Additionally, their ease of handling simplifies manufacturing processes, reducing production time and costs.

Customizability and Shape Retention

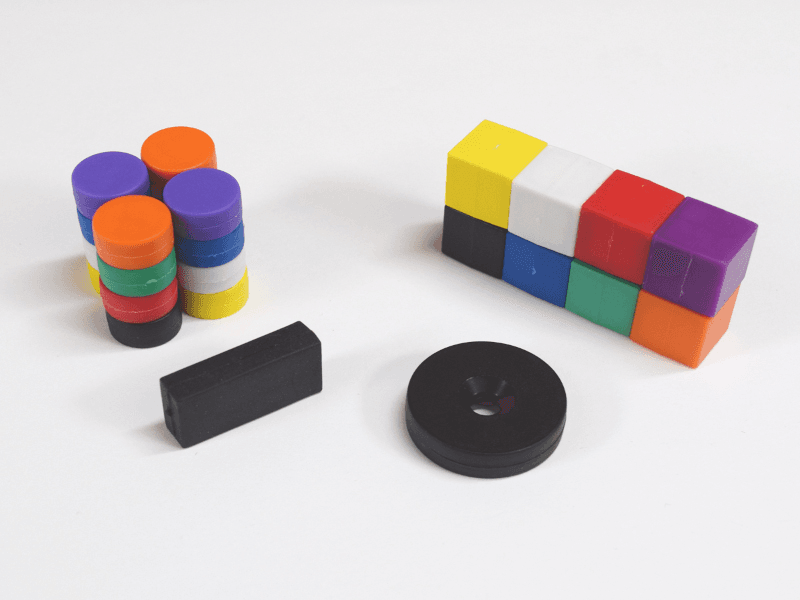

Rubber magnets can be manufactured in a wide array of shapes and sizes, tailored to meet specific requirements. They are available in sheets, strips, and various custom shapes, offering unparalleled versatility. This customizability is particularly advantageous for businesses seeking unique promotional items or for manufacturers requiring specific geometric configurations for their products.

Safe and Durable

Rubber magnets are generally safer to handle compared to their metal or ceramic counterparts. They pose less risk of breakage and do not have sharp edges that could cause injury. Additionally, their rubber composition provides a degree of protection against environmental factors such as moisture, dust, and vibrations, enhancing their durability and longevity in various settings.

Cost-Effective

In many cases, rubber magnets are more cost-effective than traditional magnets. Their production processes are often less complex, and the raw materials used are relatively inexpensive. This cost efficiency makes rubber magnets an attractive option for large-scale production and budget-conscious projects.

Magnetic Properties and Performance

While rubber magnets may not match the magnetic strength of neodymium or ceramic magnets, they still offer satisfactory magnetic performance for many applications. They are commonly used in applications where strong magnetic fields are not required, such as in magnetic closures, decorative items, and lightweight holding solutions.

The Limitations of Rubber Magnets

Limited Magnetic Strength

One of the primary limitations of rubber magnets is their relatively low magnetic strength compared to other types of magnets. They are generally not suitable for applications that require high magnetic fields or strong holding forces. For example, in industrial applications where high magnetic strength is crucial, rubber magnets may not be the ideal choice.

Temperature Sensitivity

Rubber magnets can be sensitive to temperature variations. Extreme heat or cold can affect their magnetic properties and overall performance. High temperatures, in particular, can cause the rubber to soften or degrade, leading to a loss of magnetic strength and potential deformation of the magnet.

Limited Resistance to Harsh Environments

While rubber magnets offer some protection against moisture and dust, they may not be suitable for use in extremely harsh environments. For instance, in applications exposed to chemicals, oils, or severe weather conditions, the rubber material may deteriorate, compromising the magnet’s effectiveness and durability.

Wear and Tear

Over time, rubber magnets can experience wear and tear due to their flexible nature. Frequent bending, twisting, or abrasion can lead to a decrease in magnetic performance and potential physical damage. This wear and tear can be a concern in high-traffic or high-use applications where the magnets are subjected to constant stress.

Limited High-Temperature Applications

Rubber magnets are generally not suitable for high-temperature applications. The rubber material can only withstand moderate temperatures before it starts to lose its magnetic properties or degrade. For applications that involve high temperatures, alternative magnetic materials with better thermal resistance may be required.

Lower Maximum Operating Temperature

Rubber magnets have a lower maximum operating temperature compared to other magnets, such as ferrite or neodymium magnets. This limitation can restrict their use in applications where high-temperature stability is essential. Users must carefully consider the operating conditions to ensure that rubber magnets are appropriate for their specific application.

Applications of Rubber Magnets

Despite their limitations, rubber magnets find a wide range of applications across various industries. Some of the notable applications include:

Consumer Products

Rubber magnets have become a staple in the consumer products market due to their versatility and customizability. One of the most common applications is in refrigerator magnets, which are often used for decorative purposes, displaying photos, or holding important notes and reminders. Their flexibility allows them to adhere to curved surfaces, making them ideal for this use. Rubber magnets are also popular in the production of promotional items, such as custom-shaped magnets for businesses, events, and organizations. These can be crafted into a wide variety of shapes and sizes, offering a unique way to promote a brand or cause.

Additionally, rubber magnets are utilized in educational toys and games. Their ability to be shaped into different forms and colors makes them engaging for children, while their magnetic properties provide an interactive learning experience. For example, magnetic building sets or puzzles often use rubber magnets due to their safety and ease of handling. This adaptability not only enhances the functionality of these products but also ensures they remain safe and durable for regular use.

Overall, the consumer products sector benefits greatly from the use of rubber magnets. Their ability to be easily molded into various shapes, combined with their safe handling properties, makes them ideal for a wide range of applications. Whether it’s for everyday items like refrigerator magnets or custom promotional products, rubber magnets offer a unique blend of flexibility, cost-effectiveness, and aesthetic appeal that continues to make them a popular choice.

Industrial Uses

In industrial settings, rubber magnets are valued for their flexibility and ease of integration into various applications. One significant use is in magnetic sealing and gaskets, where rubber magnets provide an effective solution for creating seals that prevent the ingress of dust, moisture, and other contaminants. These magnetic seals are often used in enclosures, doors, and panels where a reliable seal is essential for maintaining equipment performance and protecting sensitive components.

Rubber magnets are also employed in lightweight holding solutions. Their ability to conform to different shapes and surfaces makes them useful in applications where magnetic strength is needed but where a rigid magnet would be impractical. For example, they can be used to secure lightweight components or fixtures in place during assembly or maintenance. This application benefits from the rubber magnet’s flexibility and ease of handling, which simplifies the process of positioning and securing parts.

Additionally, rubber magnets are used in vibration dampening applications. Their rubber composition helps absorb and reduce vibrations, which is crucial in machinery and equipment where vibrations can lead to wear and tear or affect performance. By incorporating rubber magnets into the design of vibration isolation systems, industries can enhance the longevity and reliability of their equipment.

Overall, the industrial sector benefits from the use of rubber magnets due to their adaptability, ease of integration, and cost-effectiveness. Their ability to provide effective sealing, lightweight holding, and vibration dampening solutions makes them a valuable component in various industrial applications.

Automotive Industry

In the automotive industry, rubber magnets play a critical role in enhancing the performance and durability of various components. One key application is in magnetic seals and weather stripping. Rubber magnets are used to create seals around doors, windows, and other openings to prevent water, dust, and noise from entering the vehicle. These magnetic seals provide a reliable barrier that maintains the vehicle’s integrity and improves passenger comfort.

Rubber magnets are also utilized in vibration dampening applications within automotive systems. They can be incorporated into components such as engine mounts, transmission mounts, and suspension systems to absorb vibrations and reduce noise. This application is crucial for ensuring a smooth and quiet driving experience while also extending the lifespan of critical automotive components.

Furthermore, rubber magnets are used in automotive accessories and customizations. For example, they can be employed in magnetic mounts for various devices, such as phone holders, GPS units, and other electronic accessories. The flexibility and ease of use provided by rubber magnets make them an ideal choice for creating secure and adjustable mounting solutions.

Overall, the automotive industry benefits from rubber magnets due to their versatility, durability, and effectiveness in various applications. Whether used for sealing, vibration dampening, or accessory mounting, rubber magnets contribute to enhanced vehicle performance and driver satisfaction.

Aerospace and Electronics

In the aerospace and electronics industries, rubber magnets are valued for their flexibility and lightweight properties. In aerospace applications, rubber magnets are used for magnetic shielding and protective covers. They provide an effective solution for shielding sensitive electronic components from external magnetic fields, ensuring the proper functioning of avionics and other critical systems. Their ability to conform to complex shapes and adhere to various surfaces makes them ideal for use in aerospace environments.

Rubber magnets are also employed in electronics for lightweight assemblies and magnetic shields. They are used in components such as protective covers for electronic devices, magnetic closures for enclosures, and flexible magnetic mounts for various electronic applications. The rubber magnet’s flexibility allows for easy integration into electronic designs, while its lightweight nature contributes to overall device performance and portability.

Additionally, rubber magnets are used in the development of magnetic sensors and switches. Their ability to provide precise magnetic fields in a flexible form factor is beneficial for creating sensors and switches that require accurate and reliable performance in compact spaces.

Overall, the aerospace and electronics industries benefit from the use of rubber magnets due to their adaptability, lightweight nature, and effective magnetic properties. Their application in shielding, protective covers, and electronic components highlights their value in maintaining performance and reliability in advanced technological systems.

Conclusion

Rubber magnets represent a fascinating intersection of flexibility and magnetic capability, offering a range of advantages that make them suitable for diverse applications. Their versatility, ease of handling, and cost-effectiveness position them as valuable components in consumer products, industrial applications, and more. However, their limitations, including lower magnetic strength and temperature sensitivity, must be carefully considered to ensure they meet the specific requirements of each application.

By understanding the advantages and limitations of rubber magnets, engineers, designers, and manufacturers can make informed decisions about their use, balancing their unique properties with the demands of their projects. Whether used in everyday items or specialized applications, rubber magnets continue to demonstrate their value and adaptability in the ever-evolving landscape of magnetic materials.in the ever-evolving landscape of magnetic materials.