Do you remember those intense moments spent in front of a chessboard, pondering the best move to make – knight or bishop? Just as each chess piece has its own vital role, every type of magnet brings its unique strengths to the industrial world. Today, let’s delve into a familiar dilemma when it comes to buying magnets: choosing between Samarium Cobalt (SmCo) Magnets and Neodymium (NdFeB) Magnets. This decision can truly impact how well your applications perform and how long they last.

When choosing between Samarium Cobalt Magnets and Neodymium Magnets, it’s important to consider what you need them for. If you need magnets that can withstand high temperatures and tough conditions, go for Samarium Cobalt Magnets. But if you want magnets that are super strong and affordable, Neodymium Magnets might be the better choice. Just think about what you need and how much you can spend, and you’ll be able to make the right decision!

Let’s take a closer look to understand how this unfolds.

Samarium Cobalt (SmCo) vs. Neodymium (NdFeB) Magnets: What’s the Difference?

Let’s talk about SmCo and NdFeB magnets – it’s like comparing a seasoned sailor with a rookie on the magnetic stage. SmCo, the old-timer, can handle high temperatures like a pro. On the other hand, NdFeB, the young gun, has impressive magnetic strength but might need a little help when things heat up.

What Are Samarium Cobalt Magnets (SmCo)?

Samarium Cobalt (SmCo) Magnets are made from a mixture of samarium, cobalt, and a small amount of iron. They are super strong and can withstand high temperatures, up to 400°C! Imagine, for example, a SmCo magnet being used inside a military jet engine – even though it’s super hot, the magnet keeps its special powers.

And because SmCo magnets are naturally able to resist rusting, they don’t need to be covered up. Of course, if you did give them a little coating, it would help them be even more resistance to being worn away.

The Dynamism of Neodymium Magnets (NdFeB)

Neodymium Magnets, also known as NdFeB magnets, are really powerful magnets made up of a special mix of neodymium, iron, and boron. They have the most energy when it comes to magnets. Not just something people say, but in real life too. For example, when doctors take pictures of your insides using a big machine like MRI which stands for Magnetic Resonance Imaging, they use neodymium magnets. The images they get are better than the other pictures. But you know what? If their temperature gets hotter than 80°C (that’s 176°F), neodymium magnets don’t stay magnets anymore. They stop attracting and repelling like a magnet. That’s no good. Good news for you because there are some that stay magnets even when it’s as hot as boiling water at 220°C (that’s 428°F). They cost more money, but you get to have a different kind of neodymium magnet that does what magnets do inside machines which get hot. Just have to follow special rules and tells the magnets inside what to do before you get the price worth what they do when they’re hot.

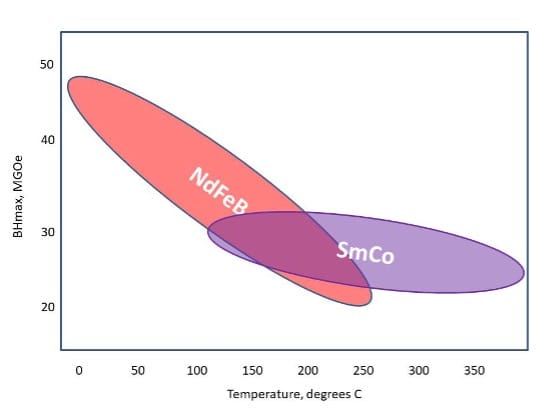

How Temperature Affects Magnets

Did you know that magnets can be affected by temperature? It’s true! Let’s break it down. A certain type of magnet called NdFeB, when it’s at a normal temperature, can hold a force of 13,500 gauss. But, if the temperature goes up, that force could go down by 5-10% or more. On the other hand, a magnet called SmCo only loses about 1% of its strength if the temperature rises. This makes SmCo magnets really good if you need them to stay strong when it’s hot outside.

About Coatings on Magnets

Coatings are like armors that protect magnets from things that could break them. For the NdFeB magnets, a lot of people use a coating called ‘triple layer nickel-copper-nickel.’ When you use that coating, your magnet can last a long time because it’s protected from water and rust. Another kind of coating you might see is called ‘epoxy.’ People use this kind of coating when they’re using magnets in hard places, like on big, tall fans in windy places. When you use epoxy, your magnet can work even if it gets rained on.

Practical Examples of Corrosion Resistance

In the world of industrial applications, the choice between SmCo and NdFeB magnets must consider the environment’s corrosive potential.

SmCo magnets excel in chemical processing plants, where they resist harsh chemicals without degradation, while NdFeB magnets shine in consumer electronics, leveraging their superior magnetic strength and being shielded from harsh conditions. Although SmCo magnets may require a higher initial investment, their exceptional corrosion resistance can provide greater lifetime value in corrosive environments, eliminating the need for frequent replacement. Conversely, Neodymium magnets, although more cost-effective upfront, may see their advantage erode in situations where corrosion could lead to premature failure, requiring additional budgeting for maintenance or replacements.

The choice ultimately depends on the specific environmental conditions and the long-term cost-effectiveness of the solution, as industrial decision-makers strive to select the magnet technology that best meets the demands of their application.

Here’s the bottom line: When you’re deciding which magnet to use, you need to think about how much it’s going to cost you and what you’re going to use it for.

Choosing Magnets: What You Need to Know

Let’s talk about NdFeB magnets first. They’re cheaper when you buy them, but they might end up costing you more in the long run because you have to replace them all the time. Why would you have to replace them all the time? Because they don’t like heat, and if you put them somewhere hot, they’ll stop working and you’ll have to get new ones.

On the other hand, we have SmCo magnets. They’re more expensive when you buy them, but if you’re using them somewhere hot, they’ll probably be the cheaper option because you won’t have to replace them. For example, if you need a magnet in an airplane or something that’s flying around where it gets hot, you’re going to have to buy the more expensive magnet because it will work better when it’s hot.

Wrapping It Up: Making the Right Choice

The decision between SmCo and NdFeB should be guided by a blend of factors: temperature range, magnetic strength, environmental conditions, and economic considerations. The success of your application could hinge on the nuances of these magnetic materials.

Magnetize Your Business with Expertise

MagnetsTek is poised to provide tailored advice, helping you make an informed decision between SmCo and NdFeB magnets. Contact us at [email protected] for a consultation that could propel your project to the next level.

Related

NdFeB Magnets VS Ferrite Magnets