I. Introduction

In the vast world of magnetic materials, ferrites hold a crucial place due to their versatile applications and unique properties. From the speakers in our devices to essential components in power supplies, ferrites quietly power a significant part of modern technology. Yet, not all ferrites are created equal. The distinction between soft ferrites and hard ferrites can spell the difference between optimal performance and inefficiency in various applications. This article delves into the fascinating world of ferrites, exploring the fundamental differences between soft and hard ferrites, their advantages, and the specific contexts where each type excels.

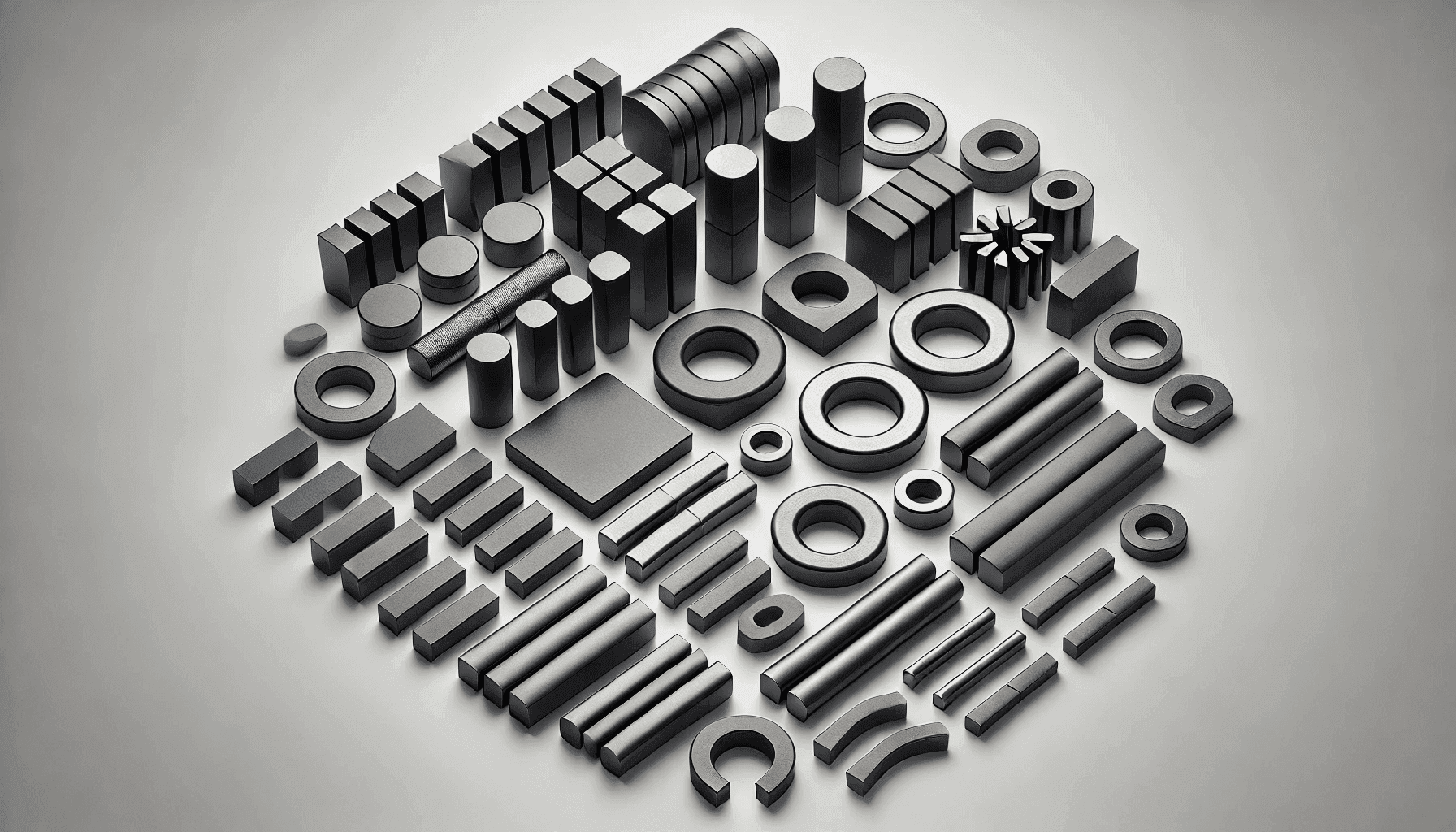

II. What Are Ferrites?

Definition

Ferrites are ceramic compounds consisting of iron oxide (Fe2O3) combined with additional metallic elements. These materials exhibit ferromagnetic properties, meaning they can be magnetized or attracted to a magnet. Ferrites are known for their high electrical resistivity and low eddy current losses, making them ideal for high-frequency applications.

Types

Ferrites are broadly categorized into two types: soft ferrites and hard ferrites. This classification is based on their magnetic properties, particularly coercivity, which measures the resistance of a material to becoming demagnetized.

Importance

Ferrites are indispensable in numerous industries, including electronics, automotive, telecommunications, and consumer goods. Their ability to manage magnetic fields efficiently and their cost-effectiveness make them preferred materials for a wide range of applications.

III. Differences Between Soft and Hard Ferrites

| Soft Ferrites | Hard Ferrites | |

| Composition | MnO · Fe2O3, ZnO · Fe2O3, Mn-Mg-Zn · Fe2O4, etc. | BaO · 6Fe2O3, SrO · 6Fe2O3, etc. |

| Features | high magnetic permeability and low coercivity; lower magnetic strength; | low magnetic permeability and high coercivity; larger magnetic force; |

| Applications | high-frequency applications; | transformers; motors; speakers; |

Magnetic Properties

The primary difference between soft and hard ferrites lies in their magnetic coercivity. Soft ferrites have low coercivity, meaning they can be easily magnetized and demagnetized. This makes them ideal for applications where the magnetic field needs to be frequently switched or modulated. In contrast, hard ferrites have high coercivity, allowing them to maintain a permanent magnetization once they are magnetized. This characteristic makes them suitable for permanent magnets used in various devices and machinery.

Chemical Composition

Soft ferrites typically consist of compounds like manganese-zinc (MnZn) or nickel-zinc (NiZn), while hard ferrites are usually made from compounds such as strontium ferrite (SrFe12O19) or barium ferrite (BaFe12O19). These compositional differences contribute to their distinct magnetic properties and applications.

Physical Properties

Physically, soft ferrites are usually more brittle and can be easily shaped and processed. Hard ferrites, on the other hand, are generally tougher and more resistant to physical stress. This makes hard ferrites more suitable for applications requiring durable, long-lasting magnetic materials.

Applications

Soft ferrites are predominantly used in applications like inductors, transformers, and electromagnetic interference (EMI) suppression, where their ability to switch magnetic states rapidly is beneficial. Hard ferrites are used in permanent magnets for motors, generators, speakers, and various household and industrial devices where a stable, long-term magnetic field is needed.

IV. Advantages of Soft Ferrites

High Permeability

One of the standout features of soft ferrites is their high magnetic permeability. This means they can support a large amount of magnetic flux, making them ideal for transformer cores and inductors, where efficient magnetic field management is crucial.

Low Coercivity

Soft ferrites’ low coercivity minimizes energy losses during magnetization and demagnetization cycles. This characteristic is especially advantageous in high-frequency applications, such as power supplies and radio frequency (RF) circuits, where rapid magnetic switching is required.

Frequency Response

Soft ferrites excel in high-frequency environments due to their low eddy current losses. They can operate efficiently at frequencies ranging from a few kilohertz to several megahertz, making them essential in modern electronic devices that operate at these frequencies.

Cost-Effectiveness

The production of soft ferrites is relatively cost-effective, particularly for large-scale applications. Their composition and manufacturing processes allow for economical production, which translates to lower costs for industries relying on these materials.

Examples of Soft Ferrites

Soft ferrites are indispensable in a wide array of applications due to their magnetic properties and efficiency in high-frequency environments. Here, we’ll explore some prominent examples of soft ferrites and their specific uses, highlighting why these materials are so crucial in modern technology.

MnZn Ferrites: Powering Efficiency in Power Applications

Manganese-zinc ferrites (MnZn) are among the most widely used soft ferrites, thanks to their high magnetic permeability and low power losses at frequencies up to 1 MHz. These properties make MnZn ferrites ideal for use in power inductors, transformers, and electromagnetic interference (EMI) filters. In power supplies and inverters, MnZn ferrites efficiently manage the magnetic fields, ensuring minimal energy loss and optimal performance. Their ability to operate efficiently at lower frequencies also makes them perfect for use in switch-mode power supplies (SMPS), where maintaining efficiency and reducing heat generation is critical.

NiZn Ferrites: The Backbone of High-Frequency Applications

Nickel-zinc ferrites (NiZn) are preferred for applications requiring excellent performance at high frequencies, typically ranging from 1 MHz to several hundred megahertz. These ferrites are commonly used in antennas, RF transformers, and broadband transformers. Their high electrical resistivity and low eddy current losses enable them to perform exceptionally well in RF circuits, reducing signal loss and improving overall system efficiency. For example, in telecommunications equipment, NiZn ferrites ensure clear signal transmission and reception, making them a vital component in devices like mobile phones, Wi-Fi routers, and radio transmitters.

Other Types of Soft Ferrites: Tailored for Specialized Applications

While MnZn and NiZn ferrites are the most common, other soft ferrites like magnesium-zinc (MgZn) and lithium-zinc (LiZn) ferrites are used in specific high-frequency and high-temperature applications. MgZn ferrites, for instance, are known for their stable performance at elevated temperatures, making them suitable for use in industrial and automotive applications where heat resistance is essential. LiZn ferrites, on the other hand, are prized for their unique properties in niche applications, such as specialized sensors and high-frequency transformers.

In each of these examples, the specific properties of the soft ferrite material are matched to the demands of the application, ensuring optimal performance and reliability. Whether it’s the high permeability of MnZn ferrites in power applications or the low eddy current losses of NiZn ferrites in high-frequency circuits, these materials play a crucial role in advancing technology and enhancing efficiency in various fields.VI. Advantages of Hard Ferrites

High Coercivity

The high coercivity of hard ferrites is their most defining characteristic. This property ensures that once magnetized, hard ferrites retain their magnetic properties indefinitely, making them ideal for permanent magnets in various applications.

Durability

Hard ferrites are physically robust and resistant to demagnetization from external magnetic fields or physical stress. This durability makes them suitable for harsh environments and applications where long-term reliability is essential.

Wide Availability

Hard ferrites, especially those based on strontium and barium compounds, are abundant and easily manufactured. This availability ensures a steady supply for industries requiring large quantities of permanent magnets.

Cost-Effectiveness

Compared to rare-earth magnets, hard ferrites are much more economical. Their lower production costs and widespread availability make them a cost-effective choice for applications that do not require the superior magnetic strength of rare-earth magnets.

Applications of Hard Ferrites

Motors and Generators

Hard ferrites are extensively used in electric motors and generators. Their ability to maintain a strong and stable magnetic field enhances the efficiency and reliability of these machines.

Consumer Electronics

In consumer electronics, hard ferrites are found in speakers, headphones, and other audio devices. Their stable magnetic properties ensure consistent performance and sound quality.

Automotive Industry

The automotive industry relies on hard ferrites for various sensors, actuators, and motor applications. Their durability and resistance to demagnetization make them suitable for the demanding conditions within vehicles.

Household Items

Common household items, such as refrigerator magnets and magnetic closures, also use hard ferrites. Their cost-effectiveness and adequate magnetic strength make them perfect for everyday applications.

Soft Ferrites vs Hard Ferrites: A Comparative Analysis

Performance Comparison

Soft ferrites excel in applications requiring rapid magnetic switching and high-frequency operation. In contrast, hard ferrites are better suited for applications needing a stable, permanent magnetic field. Each type has unique performance characteristics that make them suitable for specific roles.

Cost Analysis

Soft ferrites, while generally cost-effective, might involve higher costs in high-frequency applications due to the need for specialized materials. Hard ferrites, being more abundant and easier to produce, offer a lower cost for permanent magnet applications. However, the choice between the two should consider not just initial costs but also long-term efficiency and reliability.

Suitability for Applications

Choosing between soft and hard ferrites depends on the specific requirements of the application. For high-frequency, low-power loss needs, soft ferrites are ideal. For permanent magnets and durability, hard ferrites are the better choice. Understanding the precise needs of an application will guide the decision.

Future Trends

The future of ferrites will likely see advancements in both soft and hard materials. Research is ongoing to improve their properties, reduce costs, and expand their applicability. Innovations in nanotechnology and material science promise even more efficient and specialized ferrites for emerging technologies.

IX. Conclusion

Ferrites play a critical role in modern technology, offering versatile solutions for various magnetic needs. Understanding the differences between soft and hard ferrites is essential for making informed decisions in designing and selecting materials for specific applications. Soft ferrites, with their high permeability and low coercivity, excel in high-frequency applications, while hard ferrites, with their high coercivity and durability, are perfect for permanent magnets. As technology continues to evolve, the demand for efficient and specialized magnetic materials will only grow, making ferrites an ever-important part of our technological landscape.

If you’re considering which type of ferrite to use for your next project or product, take a moment to assess your specific needs and consult with experts in the field. With the right choice, you can enhance performance, efficiency, and reliability in your applications.