Introduction

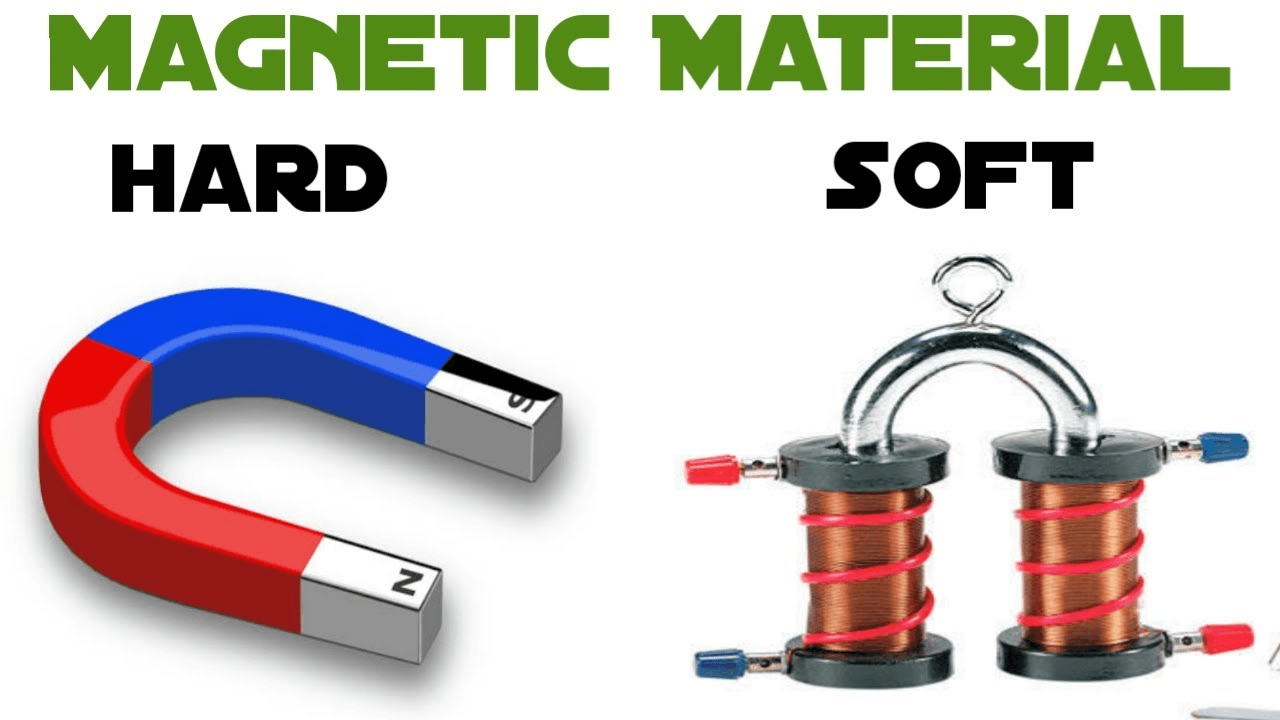

Magnetic materials are foundational to the modern industrial world. From high-efficiency transformers and electric motors to data storage devices and advanced medical imaging systems, the strategic use of magnetic materials enables innovation across sectors. These materials are typically divided into two broad categories: soft magnetic materials and hard magnetic materials. While both stem from the same physical principles, their contrasting properties make them suitable for vastly different applications.

At MagnetsTek, understanding the distinction between soft and hard magnetic materials is essential for selecting the right solution for our clients’ engineering and technological needs. This article provides an in-depth analysis of these materials, exploring their physical characteristics, applications, processing methods, and historical development.

Historical Context: From Lodestones to Magnetic Alloys

The journey of magnetism begins with lodestone, a naturally occurring magnetic mineral (magnetite) discovered over two thousand years ago. Ancient civilizations, including the Greeks and Chinese, used it for rudimentary navigation, marking the birth of magnetic materials in human history.

The industrial revolution ushered in an era where magnetic materials were engineered for specific tasks. In the early 20th century, steel magnets represented the earliest hard magnetic materials. Shortly afterward, silicon steel emerged as a soft magnetic material, particularly suited to electrical power systems. The development of Alnico in the 1930s, ferrites in the 1950s, and rare-earth magnets like NdFeB and SmCo in the 1980s further refined the capabilities of hard magnetic materials. Simultaneously, advances in metallurgy and alloying led to high-performance soft materials like permalloy, amorphous metals, and nanocrystalline alloys.

Fundamental Physics of Magnetic Behavior

At the core of magnetism lies the behavior of atomic magnetic moments—primarily due to the spin and orbital angular momentum of electrons. In ferromagnetic materials, such moments tend to align spontaneously, creating magnetic domains.

Key Physical Concepts:

- Coercivity (Hc): The resistance of a material to changes in magnetization.

- Soft magnetic materials: Low coercivity (~1–100 A/m).

- Hard magnetic materials: High coercivity (>10⁴ A/m).

- Remanence (Br): The residual magnetization after removing the external magnetic field. Hard magnets have high remanence; soft magnets do not retain much.

- Saturation Magnetization (Ms): Maximum magnetization a material can attain under an external field.

- Permeability (μ): A measure of how easily a material can be magnetized. Soft materials typically exhibit high permeability, aiding in efficient magnetic flux conduction.

Soft Magnetic Materials: Characteristics and Applications

Key Properties

Soft magnetic materials are defined by their ease of magnetization and demagnetization. These materials exhibit:

- Low coercivity

- High magnetic permeability

- Low core losses

- Minimal hysteresis loop area

These properties make them ideal for alternating magnetic fields, such as in AC transformers and inductors.

Common Soft Magnetic Materials

- Silicon Steel (Electrical Steel):

- Contains ~3% Si

- Excellent electrical resistivity, reducing eddy current losses

- Used in transformers, motors, and generators

- Permalloy (Ni-Fe Alloys):

- Typically 80% Ni, 20% Fe

- Extremely high permeability and low coercivity

- Used in magnetic shielding and recording heads

- Ferrites:

- Ceramic materials composed of iron oxide with other metals (e.g., Mn-Zn, Ni-Zn)

- High electrical resistivity, ideal for high-frequency applications

- Found in power supply inductors, RF transformers

- Amorphous and Nanocrystalline Alloys:

- Exhibit ultra-low core losses

- High efficiency in modern power conversion systems

- Applied in solar inverters, high-frequency transformers

Real-World Applications

- Power Transformers: Use grain-oriented silicon steel to reduce losses.

- Inductive Components: Include inductors and chokes in power electronics.

- Magnetic Shielding: Permalloy is used to protect sensitive instruments.

- Electric Motors: Soft materials form the magnetic core to optimize efficiency.

Hard Magnetic Materials: Characteristics and Applications

Key Properties

Hard magnetic materials, or permanent magnets, retain their magnetization over time, even without an external field. They are characterized by:

- High coercivity

- High remanence

- Large hysteresis loop

- Strong resistance to demagnetization

These traits make hard magnets essential in static magnetic field applications where longevity and strength are critical.

Common Hard Magnetic Materials

- Alnico (Al–Ni–Co):

- Good temperature stability

- Moderate coercivity

- Used in electric guitars, sensors

- Ferrite Magnets (Ceramic Magnets):

- Composed of iron oxide and barium/strontium

- Cost-effective, corrosion-resistant

- Found in loudspeakers, fridge magnets

- Samarium Cobalt (SmCo):

- High magnetic strength, excellent temperature resistance

- Corrosion-resistant without coating

- Ideal for aerospace, military, and high-temp applications

- Neodymium-Iron-Boron (NdFeB):

- The strongest commercially available magnet

- Compact size, high energy product (BHmax)

- Used in electric vehicles, wind turbines, and robotics

Real-World Applications

- Electric Motors and Generators: NdFeB magnets enable compact, powerful designs.

- MRI Machines: Rely on high-field strength permanent magnets.

- Wind Turbines: Use SmCo or NdFeB for efficient energy conversion.

- Consumer Electronics: Headphones, HDDs, and smartphones use miniature hard magnets.

Comparative Summary: Soft vs Hard Magnetic Materials

| Property | Soft Magnetic Materials | Hard Magnetic Materials |

|---|---|---|

| Coercivity | Low (easy to magnetize/demagnetize) | High (retains magnetization) |

| Remanence | Low | High |

| Hysteresis Losses | Low | High |

| Permeability | High | Low to moderate |

| Typical Applications | Transformers, inductors, shields | Motors, magnets, data storage |

| Material Examples | Silicon steel, ferrites, permalloy | NdFeB, SmCo, ferrites, Alnico |

| Temperature Stability | Moderate to high (depends on type) | SmCo: High, NdFeB: Moderate |

Manufacturing and Processing Techniques

Soft Magnetic Materials

- Rolling and Annealing: Electrical steels undergo grain orientation and insulation coating processes.

- Powder Metallurgy: Used for ferrite cores and soft metallic composites.

- Rapid Solidification: Enables creation of amorphous strips with fine magnetic properties.

Hard Magnetic Materials

- Sintering: Common for NdFeB and SmCo, where powders are pressed and heat-treated.

- Melt Spinning: Produces bonded magnets in NdFeB, with isotropic magnetic properties.

- Injection Molding: Allows complex magnet shapes, especially for hybrid automotive use.

Emerging Trends and Innovations

For Soft Magnetic Materials

- High-frequency power electronics are pushing the limits of nanocrystalline materials.

- 3D printed soft magnetic composites are revolutionizing prototyping in motor design.

- Development of low-loss magnetic steels for energy-efficient power transmission.

For Hard Magnetic Materials

- Rare-earth supply concerns have accelerated research into RE-free magnets.

- Grain boundary diffusion technology enhances coercivity in NdFeB without reducing remanence.

- Use of AI and simulation to optimize magnetic design for lightweight EV components.

Environmental and Economic Considerations

The extraction and processing of magnetic materials, especially rare-earth elements, pose significant environmental challenges. Recycling of hard magnets and substitution with eco-friendly ferrites or ceramic composites are gaining attention.

MagnetsTek prioritizes sustainable sourcing and green manufacturing processes, aligning with global decarbonization goals.

Conclusion

The distinction between soft and hard magnetic materials is not merely academic—it determines the feasibility, efficiency, and performance of technologies across energy, transportation, electronics, and medical fields. Soft magnets enable dynamic field manipulation, essential for electrical grids and signal conditioning. Hard magnets provide enduring magnetic strength, forming the backbone of countless electromechanical systems.

For engineers and procurement teams working with MagnetsTek, a deep understanding of these materials translates directly into smarter product design, longer operational lifetimes, and greater system efficiency. Whether you’re specifying materials for a high-frequency inverter core or a high-performance traction motor, selecting the right magnetic class is the first step toward success.

FAQs & Trends: Your Questions, Answered

Let’s address the internet’s burning questions, weaving them into our narrative for a seamless read.

1. “Why can’t we use hard magnets in transformers?”

Transformers rely on soft magnetic materials like electrical steel because they must constantly reverse magnetization (50–60 Hz in power grids). Hard magnets, with their high coercivity, would overheat and waste energy due to hysteresis losses. Imagine trying to bend a steel bar back and forth rapidly—it’s neither efficient nor sustainable.

2. “Are neodymium magnets the future of hard magnets?”

Yes, but with caveats. NdFeB magnets dominate EVs and wind turbines due to their unmatched strength. However, they rely on rare-earth elements like neodymium and dysprosium, which are scarce and geopolitically concentrated (China controls 90% of production). Researchers are racing to develop alternatives, such as iron-nitride (FeN) magnets, to reduce this dependency.

3. “Can soft magnets lose their properties over time?”

Soft magnets can degrade through:

- Mechanical Stress: Bending or annealing alters their microstructure.

- Temperature: Excessive heat reduces permeability (e.g., transformers failing during power surges).

However, they’re designed for durability in their intended applications—a well-made transformer core lasts decades.

4. “Why are hard magnets so brittle?”

Most hard magnets, like NdFeB, have complex crystalline structures that prioritize magnetic performance over mechanical strength. For instance, neodymium magnets are often coated with nickel or epoxy to prevent chipping.

5. “Do electric cars use both soft and hard magnets?”

Absolutely. Here’s how:

- Soft Magnets: Silicon steel cores in motors and inverters ensure efficient power conversion.

- Hard Magnets: NdFeB magnets in the rotor create a persistent field, boosting motor efficiency by 10–15% compared to induction motors.

Tesla’s shift to permanent magnet motors in the Model 3 highlights this synergy.

6. “Which is more environmentally friendly?”

- Soft Magnets: Electrical steel and ferrites are highly recyclable. Over 90% of transformer steel is reused.

- Hard Magnets: Recycling NdFeB is challenging due to rare-earth extraction complexity. Startups like Noveon Magnetics are pioneering methods to reclaim and repurpose these materials.

7. “What happens if a hard magnet is overheated?”

Heating a magnet past its Curie temperature (e.g., 310°C for NdFeB) destroys its magnetic domains. For example, dropping a neodymium magnet into a furnace renders it useless—a critical consideration in motor design.

8. “Can AI help design better magnetic materials?”

Yes. Companies like Citrine Informatics use machine learning to predict new magnetic alloys. In 2021, researchers at TU Darmstadt used AI to discover a cobalt-nickel alloy with record-breaking magnetic stability, slashing R&D timelines from years to months.

9. “Why are rare-earth magnets so expensive?”

Rare-earth elements are:

- Geopolitically scarce: Mining is dominated by China.

- Complex to refine: Separating neodymium from ore requires toxic chemicals.

Prices surged in 2021 when China restricted exports, pushing industries to seek alternatives.

10. “What’s the role of magnets in renewable energy?”

- Wind Turbines: Direct-drive turbines use massive NdFeB magnets (up to 2 tons!) for efficient power generation.

- Solar Power: Hard magnets adjust solar panel angles in tracking systems, boosting energy yield by 25%.