The choice between Permanent Magnet Generators (PMGs) and traditional alternators has become a topic of growing importance across various industries. As technologies evolve and the demand for more energy-efficient, reliable, and sustainable solutions rises, the advantages of PMGs are becoming more apparent. Permanent Magnet Generators offer distinct benefits over traditional alternators, such as higher efficiency, compactness, reliability, and reduced maintenance costs. These features make PMGs an attractive option for applications in renewable energy systems, electric vehicles, aerospace, and more.

In this comprehensive article, we will explore the various reasons why Permanent Magnet Generators are increasingly preferred over traditional alternators. From their superior energy conversion efficiency to their impact on the environment, we will analyze every aspect of PMGs to understand their growing prominence in modern energy generation systems.

1. Understanding the Basics: PMGs vs. Traditional Alternators

Before diving into the advantages of Permanent Magnet Generators, it is essential to understand how they differ from traditional alternators. Both devices serve the same basic function: converting mechanical energy into electrical energy. However, the way they achieve this conversion varies significantly.

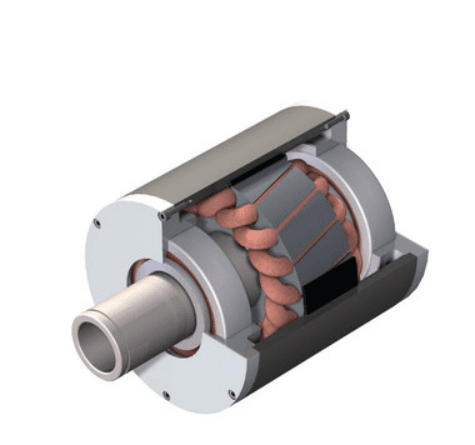

What is a Permanent Magnet Generator?

A Permanent Magnet Generator is a type of electrical generator that uses permanent magnets to create a magnetic field. This magnetic field interacts with the windings of the stator to induce an electric current. The key difference from traditional alternators lies in the absence of an external excitation system. In a PMG, the magnetic field is generated solely by the permanent magnets, which eliminates the need for an external power source to energize the rotor.

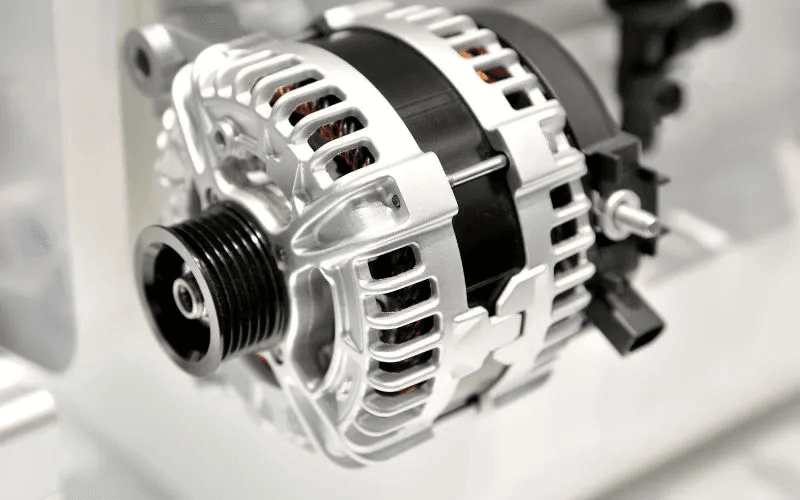

What is a Traditional Alternator?

A traditional alternator, on the other hand, relies on a rotor that is magnetized by an external current supplied by a separate excitation system. This excitation system generates a magnetic field, which then interacts with the stator to produce electrical power. Traditional alternators typically use either a wound rotor or a permanent magnet rotor. In either case, the generator requires an external energy source to create the magnetic field, making it more complex and less efficient than a PMG.

2. Higher Efficiency and Performance

One of the standout advantages of Permanent Magnet Generators is their superior efficiency compared to traditional alternators. Efficiency refers to the ability of the generator to convert mechanical energy into electrical energy, with less energy lost as heat or other forms of waste.

No Need for Excitation Power

In traditional alternators, a significant portion of the energy is lost due to the excitation system. This system consumes electrical power to magnetize the rotor, which can lead to energy waste. On the other hand, PMGs rely on the magnetic field created by permanent magnets, eliminating the need for external excitation power. This means that PMGs can deliver more energy with less waste, resulting in a higher overall efficiency.

Better Conversion of Mechanical Energy

Since PMGs do not require an external power source to generate the magnetic field, they can convert mechanical energy into electrical energy more effectively. Traditional alternators, with their need for external excitation, often experience additional losses in the process. PMGs are designed to operate with minimal internal resistance, making them more efficient in converting mechanical energy into electricity, especially at lower speeds.

Performance in Low-Speed Applications

PMG systems are particularly efficient in low-speed applications, such as wind turbines or hydroelectric generators. Traditional alternators often require higher rotational speeds to produce sufficient power. However, PMGs can generate electricity even at lower speeds, making them more suitable for renewable energy applications where the speed of the mechanical input may be low.

3. Compact Design and Weight Reduction

Another key advantage of Permanent Magnet Generators is their compact and lightweight design. PMGs have a simpler construction compared to traditional alternators, which typically consist of more components, including the excitation system and more complex rotor structures.

Smaller and Lighter

The absence of an excitation system and the simplified rotor design reduce the overall size and weight of PMGs. This makes them an ideal solution for applications where space and weight are critical factors. In industries such as electric vehicles, wind turbines, and portable power systems, the reduced size and weight of PMGs can lead to significant cost savings in terms of installation, transportation, and maintenance.

Space-Efficiency for Renewables

For renewable energy systems such as wind turbines, compactness is crucial for maximizing energy production within a limited space. PMGs are particularly well-suited for these applications, as their smaller size allows for easier integration into existing systems. In wind turbines, for example, PMGs allow for more efficient and compact generator designs, which can result in lower operational costs and higher energy yields.

4. Reliability and Durability

When choosing a generator, reliability and durability are critical factors, especially for systems that must operate continuously in challenging environments. PMGs offer a high level of reliability due to their simpler construction and fewer components that can wear out.

Fewer Moving Parts

One of the reasons why PMGs are so reliable is that they have fewer moving parts compared to traditional alternators. In a traditional alternator, the rotor must rotate within a stator to induce electrical current. The rotor typically requires brushes or slip rings to maintain a connection with the external excitation system, which can wear out over time. In contrast, PMGs use permanent magnets that generate the magnetic field without the need for slip rings, brushes, or any other components that may wear down.

Longer Lifespan

Due to the reduced wear and tear from fewer moving parts, PMGs generally have a longer operational lifespan than traditional alternators. The absence of components that require regular maintenance, such as brushes, means that PMGs can operate for extended periods without requiring significant servicing or replacement parts. This reliability is crucial in industries where downtime is costly, such as in the power generation sector or in remote applications.

Enhanced Tolerance to Harsh Conditions

PMG systems are also more tolerant of harsh environmental conditions. Traditional alternators may struggle in environments with high vibrations, extreme temperatures, or other challenging conditions. PMGs, on the other hand, are better suited to operate under such conditions because they have fewer components that can be affected by external factors. This makes PMGs ideal for applications in industries like aerospace, offshore wind power, and military technologies.

5. Lower Maintenance Costs

Another reason to choose Permanent Magnet Generators over traditional alternators is the lower maintenance costs associated with PMGs. With fewer parts that require regular maintenance, the overall cost of servicing PMGs is significantly lower than that of traditional alternators.

Reduced Maintenance Needs

Traditional alternators require ongoing maintenance to ensure the proper functioning of their excitation systems, brushes, and slip rings. Over time, these components can wear out and need to be replaced. In contrast, PMGs have no such components and require less frequent maintenance. The only maintenance typically needed for PMGs is basic inspection and cleaning, which reduces the cost and frequency of service.

Reduced Downtime

Because PMGs are more reliable and require less maintenance, they also experience less downtime compared to traditional alternators. In applications where continuous power generation is critical, such as in remote power generation systems or in electric vehicles, minimizing downtime is essential. With PMGs, the need for regular service calls and repairs is reduced, which helps keep systems running smoothly and efficiently.

Cost-Effective in the Long Run

Although the initial cost of a Permanent Magnet Generator may be higher than that of a traditional alternator, the reduced maintenance costs and longer lifespan of PMGs make them a more cost-effective option in the long run. By choosing a PMG, businesses can save on repair and replacement costs over time, leading to a better return on investment.

6. Improved Power Quality

The quality of the electrical power generated by a system is crucial, especially in applications where stable and consistent voltage is required. PMGs provide superior power quality compared to traditional alternators due to their stable magnetic field and reduced harmonic distortion.

Stable Output Voltage

In a PMG, the permanent magnets create a stable magnetic field, which results in more consistent voltage output. Traditional alternators, especially those with excitation systems, may experience voltage fluctuations or harmonic distortion due to the complexity of the magnetic field generation process. PMGs, with their simpler and more stable design, produce smoother and more reliable electrical power, which is ideal for sensitive applications such as medical equipment, high-precision machinery, and electronic devices.

Reduced Harmonic Distortion

Harmonic distortion can cause problems in electrical systems, leading to inefficiency, overheating, or malfunctioning of sensitive equipment. PMGs produce cleaner electrical power with less harmonic distortion, making them a better choice for systems that require high-quality electricity. The reduced distortion also improves the overall efficiency of the system, further enhancing the performance of the generator.

7. Environmental Benefits

Environmental sustainability is an increasingly important factor in today’s world, and Permanent Magnet Generators offer significant environmental benefits compared to traditional alternators. Their higher efficiency and reduced maintenance requirements contribute to a lower environmental impact.

Lower Energy Consumption

Because PMGs are more efficient at converting mechanical energy into electrical energy, they consume less energy overall. This results in lower fuel consumption and fewer emissions, particularly in applications like power generation and transportation. In industries focused on reducing their carbon footprint, PMGs offer a cleaner, more sustainable solution.

Reduced Electronic Waste

Traditional alternators, with their complex construction and frequent need for maintenance, often result in more waste over time. The need for spare parts and the eventual replacement of worn-out components can contribute to increased electronic waste. PMGs, with their longer lifespan and fewer components, generate less waste and contribute to a more sustainable approach to energy generation.

Ideal for Renewable Energy Applications

PMGs are particularly well-suited for renewable energy systems, such as wind turbines, solar power generation, and hydroelectric power. These applications rely on efficient, clean energy production, and PMGs are ideal for maximizing energy output with minimal environmental impact. By using PMGs in renewable energy systems, industries can reduce their reliance on fossil fuels and contribute to global sustainability efforts.

8. Conclusion

Permanent Magnet Generators offer numerous advantages over traditional alternators, making them a preferred choice in many modern applications. With their superior efficiency, compact design, reliability, reduced maintenance costs, and environmental benefits, PMGs are ideal for industries seeking to improve energy production and reduce operational costs. Whether in renewable energy systems, electric vehicles, aerospace, or industrial applications, PMGs provide a reliable, efficient, and sustainable solution that outperforms traditional alternators in numerous ways.

As technologies continue to evolve, the demand for efficient, durable, and environmentally friendly power generation solutions will only increase. Permanent Magnet Generators are well-positioned to meet these demands, making them the future of energy generation in a wide range of industries.