Introduction

Magnets are essential components in numerous technologies, from household appliances to sophisticated industrial machinery. As technology advances, so do the methods of producing and utilizing magnets. Recently, injection-molded magnets have gained attention for their innovative production techniques and cost efficiency. However, traditional magnets, with their long history and proven performance, remain crucial in many applications. This article explores the differences between injection-molded and classic magnets, providing an in-depth comparison of their properties, manufacturing processes, applications, and future trends.

Understanding Traditional Magnets

Types of Traditional Magnets

Traditional magnets have been used in various applications for decades and are categorized based on their material composition. Each type has distinct characteristics that make it suitable for specific uses.

Ferrite Magnets

Ferrite magnets are composed of iron oxide mixed with either barium or strontium carbonate. They are known for their:

- High Resistance to Demagnetization: Ferrite magnets maintain their magnetic properties over time, even in varying environmental conditions.

- Low Cost: The materials used are relatively inexpensive, making ferrite magnets a cost-effective option for many applications.

- Applications: Commonly found in small electric motors, loudspeakers, and magnetic sensors.

Ferrite magnets are produced through a sintering process where the mixed powders are heated to high temperatures to form a solid, magnetic material.

Alnico Magnets

Alnico magnets are made from a combination of aluminum, nickel, and cobalt. They are valued for their:

- Strong Magnetic Fields: They generate powerful magnetic fields compared to other types of magnets.

- Temperature Stability: Alnico magnets can operate effectively at elevated temperatures, up to 550°C.

- Applications: Widely used in electric guitars, microphones, and various sensors.

The production of alnico magnets involves casting the alloy into a mold, followed by heat treatment to enhance their magnetic properties.

Rare-Earth Magnets

Rare-earth magnets, including neodymium (NdFeB) and samarium-cobalt (SmCo), are renowned for their:

- Exceptional Magnetic Strength: They offer some of the highest magnetic strengths available.

- Resistance to Demagnetization: Especially true for samarium-cobalt magnets, which have high coercivity.

- Applications: Utilized in high-performance applications such as MRI machines, electric vehicle motors, and hard disk drives.

These magnets are typically produced through sintering or bonded processes, which involve high temperatures and pressures to form the final magnet.

Manufacturing Processes

Traditional magnets are produced using several methods, each with its own advantages and complexities:

- Sintering: Involves heating magnetic powders to a temperature below their melting point, causing them to fuse together. This process is common for ferrite and rare-earth magnets.

- Casting: Used for alnico magnets, this involves pouring molten alloy into a mold and allowing it to cool and solidify.

- Bonding: Involves mixing magnetic powders with a binder and then forming the mixture into magnets through processes like compression molding.

These methods, while effective, can be costly and time-consuming, particularly for producing magnets with specific shapes or high-performance specifications.

The Rise of Injection-Molded Magnets

The Injection-Molding Process

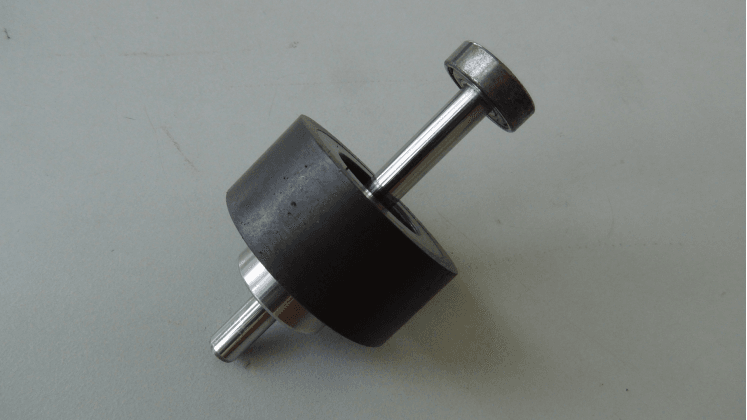

Injection-molded magnets represent a modern approach to magnet production, offering several advantages over traditional methods. The process involves:

Material Preparation

- Magnetic Powder: Composed of materials like ferrite or rare-earth compounds, the magnetic powder is combined with a polymer binder to create a mixture that can be molded.

- Binder Selection: The polymer binder is chosen based on its ability to cure properly and its compatibility with the magnetic powder.

Injection Molding

- Mold Design: Custom molds are designed to shape the magnet into the desired form. This process allows for intricate designs and complex geometries.

- Injection: The prepared mixture is injected into the mold under high pressure. This step ensures that the mixture fills all parts of the mold, creating a uniform magnet.

Curing

- Heating: The filled mold is heated to cure the polymer binder, solidifying the magnet. This step also enhances the magnetic properties of the finished product.

- Cooling: After curing, the mold is cooled to harden the magnet before it is ejected from the mold.

Finishing

- Machining: Additional processing may be required to achieve precise dimensions or surface finishes.

- Coating: Magnets may be coated to improve their resistance to corrosion or to enhance their appearance.

Advantages of Injection-Molded Magnets

- Design Flexibility: The injection-molding process allows for the creation of complex shapes and designs that might be difficult or expensive to achieve with traditional methods.

- Cost Efficiency: Lower production costs due to reduced material waste and faster manufacturing times.

- Rapid Production: High-speed production capabilities make it ideal for large volumes and quick turnaround times.

Comparing Magnetic Properties

Magnetic Strength

The magnetic strength of a magnet is a critical factor for many applications. Traditional magnets, especially rare-earth types, generally offer superior strength compared to injection-molded magnets.

- Rare-Earth Magnets: Known for their high magnetic flux density, making them suitable for applications requiring powerful magnets.

- Injection-Molded Magnets: While they offer good magnetic performance, they typically fall short of the strength provided by rare-earth magnets.

Coercivity

Coercivity is a measure of a magnet’s ability to resist demagnetization. This property is crucial for applications exposed to fluctuating magnetic fields.

- Traditional Magnets: Rare-earth magnets exhibit high coercivity, making them suitable for demanding environments.

- Injection-Molded Magnets: Can be engineered to have adequate coercivity, but may not match the levels achieved by traditional magnets.

Temperature Stability

The ability of a magnet to maintain its properties at high temperatures is another important consideration.

- Traditional Magnets: Alnico and rare-earth magnets can operate effectively at high temperatures, making them ideal for high-temperature environments.

- Injection-Molded Magnets: Limited by the thermal stability of the polymer binder, which can restrict their use in high-temperature applications.

Manufacturing Processes: Efficiency, Cost, and Precision

Traditional Manufacturing

The traditional manufacturing processes for magnets involve several steps, each with its own cost and efficiency considerations:

- Sintering: Effective for creating strong magnets, but involves high energy consumption and longer production times.

- Casting: Suitable for producing alnico magnets, but the process can be slow and costly.

- Bonding: Allows for the creation of complex shapes, but the cost of materials and production can be high.

Injection Molding

Injection molding offers several advantages over traditional methods:

- Cost Efficiency: Lower production costs due to reduced material waste and faster manufacturing times.

- Design Flexibility: Allows for the creation of complex and customized shapes, which can be difficult with traditional methods.

- Precision: High precision in manufacturing, leading to consistent quality and performance.

Applications and Use Cases

Electronics

In the electronics industry, the choice of magnet type can significantly impact performance and cost.

- Injection-Molded Magnets: Used in consumer electronics like compact speakers and headphones, where design flexibility and cost efficiency are crucial.

- Traditional Magnets: Employed in high-performance electronics such as hard disk drives and MRI machines, where superior magnetic strength is required.

Automotive

The automotive industry benefits from both types of magnets, depending on the application.

- Traditional Magnets: Preferred for motors and sensors due to their high strength and temperature stability.

- Injection-Molded Magnets: Used in applications where cost efficiency and design flexibility are prioritized, such as in some automotive components.

Consumer Goods

In consumer goods, the choice of magnet often depends on aesthetic and cost considerations.

- Injection-Molded Magnets: Commonly used in products like refrigerator magnets and magnetic closures, where affordability and design flexibility are important.

- Traditional Magnets: Used in applications requiring robust and reliable magnetic performance.

Environmental Impact and Sustainability

Traditional Magnets

The production of traditional magnets, particularly those involving rare-earth materials, can have significant environmental impacts:

- Mining and Processing: Rare-earth mining and processing can result in substantial environmental damage, including habitat destruction and pollution.

- Efforts to Improve: There are ongoing efforts to improve the sustainability of rare-earth magnet production, including recycling and more environmentally friendly mining practices.

Injection-Molded Magnets

Injection-molded magnets offer potential environmental benefits but also pose challenges:

- Reduced Material Waste: The injection-molding process minimizes material waste compared to traditional methods.

- Energy Consumption: Lower energy consumption during production compared to traditional methods, but the environmental impact of polymer binders must be considered.

- Sustainability: Research is ongoing to develop more sustainable polymers and recycling methods for injection-molded magnets.

Cost-Benefit Analysis

Traditional Magnets

The cost of traditional magnets varies based on material and production complexity:

- Material Costs: Rare-earth materials can be expensive, affecting the overall cost of the magnets.

- Production Costs: Processes like sintering and casting can be costly and time-consuming, particularly for high-performance magnets.

Injection-Molded Magnets

Injection-molded magnets typically offer a lower cost per unit:

- Lower Production Costs: Reduced material waste and faster production times contribute to cost savings.

- Initial Investment: Significant initial investment in molds and equipment can be required, but this cost is offset by the benefits of high-volume production.

Future Trends and Innovations

Advancements in Injection-Molded Magnets

Ongoing research aims to enhance the performance and sustainability of injection-molded magnets:

- Improved Magnetic Properties: Efforts are being made to enhance the magnetic strength and coercivity of injection-molded magnets.

- Sustainable Materials: Development of more environmentally friendly polymer binders and materials is a key focus.

Emerging Technologies

Future advancements in magnet technology are expected to drive innovation in both types of magnets:

- Material Science: Advances in material science may lead to new types of magnets with improved performance and reduced environmental impact.

- Manufacturing Techniques: Innovations in manufacturing techniques, such as additive manufacturing and advanced molding technologies, could further enhance the capabilities of both traditional and injection-molded magnets.

Conclusion

The comparison between injection-molded and traditional magnets reveals distinct advantages and challenges for each type. Traditional magnets, with their superior magnetic strength and temperature stability, remain essential for high-performance applications. In contrast, injection-molded magnets offer design flexibility, cost efficiency, and rapid production, making them suitable for a range of consumer and industrial applications.

As technology continues to evolve, both types of magnets will play crucial roles in shaping the future of magnetic technology. By understanding their unique properties and applications, industries can make informed decisions to leverage the best magnet technology for their needs.