Introduction

The interplay between magnetic fields and liquid metals is an area of research and industrial application that spans across metallurgy, energy, and materials science. Liquid metals—such as gallium, mercury, and molten aluminum—exhibit unique behaviors when exposed to magnetic fields. Understanding how magnets affect these metals is crucial for both fundamental physics and practical applications. In particular, high-performance permanent magnets like NdFeB magnets (Neodymium-Iron-Boron) and SmCo magnets (Samarium-Cobalt) have proven invaluable due to their exceptional magnetic strength and thermal stability. This article explores the scientific principles behind magnetic influence on liquid metals, reviews industrial applications, and considers future prospects in this evolving field.

Background on Liquid Metals and Magnetism

Liquid metals have intrigued scientists for decades because of their excellent electrical and thermal conductivity, as well as their fluidity at elevated temperatures. In various industrial processes—ranging from casting and welding to cooling systems in nuclear reactors—the controlled manipulation of liquid metals is vital.

Properties of Liquid Metals

Liquid metals typically possess high densities and conductivities that allow them to respond robustly to electromagnetic forces. The atomic structure and metallic bonding in these substances enable free electron movement, which becomes the primary driver for induced currents when subjected to magnetic fields. These phenomena lay the groundwork for many applications and experimental techniques in metallurgy and fluid dynamics.

Overview of Magnetic Materials: NdFeB and SmCo

Among the different types of magnets, two classes stand out for their ability to generate strong, stable magnetic fields in challenging environments:

- NdFeB Magnets: Known for their very high magnetic energy density, NdFeB magnets are widely used in applications requiring strong, compact magnetic fields. Their remarkable strength makes them suitable for precision control in systems where magnetic forces are used to influence conductive fluids.

- SmCo Magnets: SmCo magnets are prized for their high thermal stability and resistance to corrosion. They are particularly useful in high-temperature applications where conventional magnets, such as those made of neodymium, might suffer degradation or demagnetization.

Together, these magnets provide complementary benefits in industrial and scientific settings that involve liquid metals.

Scientific Principles of Magnet-Liquid Metal Interactions

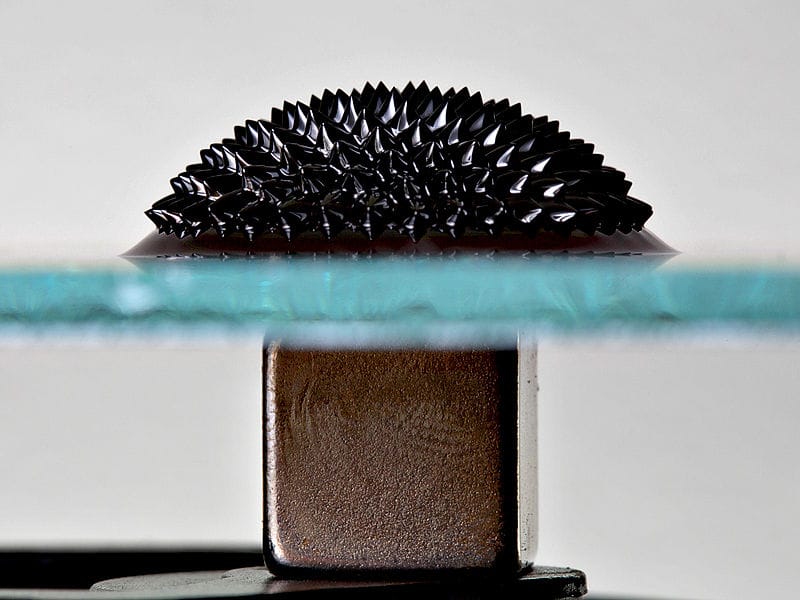

Magnetohydrodynamics (MHD)

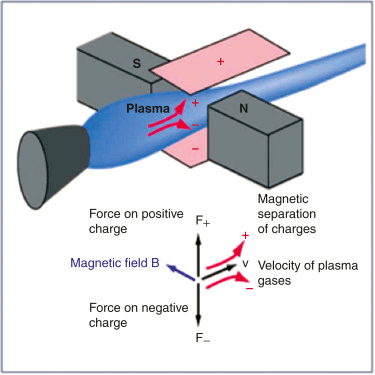

At the core of understanding the magnetic effects on liquid metals lies the field of magnetohydrodynamics (MHD). MHD combines the principles of electromagnetism and fluid dynamics to study the behavior of electrically conductive fluids in magnetic fields. When a liquid metal flows in the presence of a magnetic field, several interesting phenomena emerge:

Induction of Eddy Currents: As the metal moves, it generates eddy currents—localized loops of electrical current induced by the magnetic field. These currents create secondary magnetic fields that interact with the applied field.

Lorentz Force: The interaction between the eddy currents and the external magnetic field produces Lorentz forces. These forces can alter the flow of the liquid metal by accelerating, decelerating, or even redirecting its path.

For instance, in electromagnetic stirring applications during metal casting, the Lorentz force is used to homogenize the melt, promoting uniform temperature distribution and refined microstructures upon solidification.

Thermal Effects and Solidification Dynamics

Another significant aspect is the role of magnets in modifying the solidification process of metals:

- Crystal Growth Control: By applying a magnetic field during the cooling phase, the growth patterns of crystals can be influenced. This results in a finer grain structure and improved mechanical properties of the solidified metal.

- Heat Distribution: The thermal conductivity of liquid metals coupled with magnetic manipulation allows for enhanced heat transfer. In high-performance cooling systems, this means better management of hotspots and more efficient overall cooling.

These effects are especially beneficial in industries that require high-quality metal components, such as aerospace and automotive manufacturing.

Industrial Applications

The practical applications of magnetic influence on liquid metals are numerous and span several industries. Here, we discuss some key examples where the technology is making a significant impact.

Electromagnetic Stirring in Metal Casting

During the casting process, achieving uniformity in the liquid metal is paramount. Variations in flow and temperature can lead to defects or inhomogeneities in the final product. By employing strong magnets—often utilizing NdFeB magnets—engineers can induce electromagnetic stirring. This process promotes:

- Uniform Temperature Distribution: Ensuring that the molten metal cools evenly.

- Enhanced Material Properties: Improved grain structure and reduced impurities result in stronger, more reliable materials.

- Reduced Defects: Turbulence is minimized, which is crucial for high-precision applications.

Liquid Metal Cooling Systems

In advanced nuclear reactor designs, liquid metals such as sodium or lead are employed as coolants due to their superior thermal properties. The effectiveness of these cooling systems can be further improved by magnetic manipulation:

- Flow Optimization: SmCo magnets are particularly useful because of their thermal stability in high-temperature environments. They help steer the coolant flow to avoid hot spots, thus maintaining reactor safety and efficiency.

- Enhanced Heat Transfer: By controlling the motion of the liquid metal, engineers can improve the overall thermal conductivity, which is critical in maintaining optimal reactor performance.

Electromagnetic Pumps for Liquid Metal Transport

Traditional mechanical pumps face significant challenges when handling aggressive, high-temperature liquid metals. Electromagnetic pumps provide a non-mechanical alternative, leveraging magnetic forces to induce movement:

- Reduced Mechanical Wear: With no moving parts in contact with the liquid metal, these pumps suffer less wear and tear, leading to increased longevity.

- Improved Efficiency: Using magnets like SmCo in these pumps enables operation under extreme conditions, where durability is as important as performance.

- Safety Considerations: Minimizing the mechanical components reduces the risk of contamination and leaks, which is crucial in handling hazardous materials.

Magnetic Damping in Welding and Additive Manufacturing

Welding and additive manufacturing processes often involve rapid cooling and significant thermal gradients. These conditions can lead to vibrations and instabilities in the liquid metal pool:

- Stabilization of Molten Pool: Magnetic damping using NdFeB magnets can help stabilize the liquid metal during these processes. This stabilization leads to improved precision and a reduction in structural defects.

- Control over Cooling Rates: The application of magnetic fields can also help control the cooling rate, thereby influencing the microstructure of the weld or additively manufactured component.

- Enhanced Repeatability: Improved control results in more consistent outcomes, which is particularly important in high-volume manufacturing.

Experimental Studies and Advances in Research

Numerous experimental studies have been conducted to investigate the dynamics of liquid metals under magnetic fields. Researchers utilize advanced diagnostics and computational simulations to understand and optimize these interactions.

Laboratory-Scale Experiments

Laboratory experiments often involve small-scale setups where researchers can carefully control variables such as magnetic field strength, flow rate, and temperature. Key findings from these studies include:

- Eddy Current Patterns: Visualization techniques have allowed scientists to map the eddy current patterns in various liquid metals, providing insight into how different field strengths affect flow dynamics.

- Flow Pattern Analysis: High-speed imaging and particle image velocimetry (PIV) are used to analyze the turbulent flow regimes and identify how magnetic fields can suppress unwanted fluctuations.

- Material Characterization: By solidifying the metal under controlled magnetic fields, researchers can assess changes in grain size, texture, and other mechanical properties.

Numerical Simulations

Computational models complement experimental work by providing a framework to simulate complex magnetohydrodynamic (MHD) interactions:

- Modeling Lorentz Forces: Simulations help predict how Lorentz forces will impact the flow of liquid metals in various geometries and configurations.

- Thermal and Fluid Dynamics: Coupled thermal-fluid dynamic models provide insight into how heat transfer is affected by magnetic manipulation, guiding the design of more efficient cooling systems.

- Predictive Design Tools: Advances in computational power now allow for the creation of predictive tools that can optimize industrial processes before they are implemented in the field.

Challenges and Limitations

Despite the promising applications, several challenges must be addressed when employing magnets in liquid metal systems.

Corrosion and Material Degradation

- High-Temperature Environments: In extreme temperature conditions, magnets—especially NdFeB types—can undergo corrosion or demagnetization. Protective coatings and alternative magnet materials such as SmCo help mitigate these issues, but they add complexity and cost to the system.

- Chemical Reactions: Some liquid metals may react chemically with the materials of the magnets or their protective layers, reducing their effectiveness over time.

Energy Consumption and System Complexity

- Power Requirements: Magnetic manipulation systems often require significant electrical energy to maintain high magnetic fields, particularly in industrial-scale applications.

- Control Systems: Integrating advanced control systems to dynamically adjust the magnetic field in response to changing conditions adds to the overall system complexity and cost.

- Maintenance Challenges: Regular maintenance and calibration of magnetic systems can be demanding, especially in harsh industrial environments.

Safety Considerations

- Toxicity of Liquid Metals: Certain liquid metals, like mercury, are highly toxic. The introduction of strong magnetic fields in these systems necessitates careful safety protocols to prevent accidental exposure.

- Electromagnetic Interference: High-intensity magnetic fields can interfere with nearby electronic equipment, requiring additional shielding and isolation measures.

Future Prospects and Emerging Technologies

The future of magnetic control of liquid metals is bright, with ongoing research and development promising to overcome current challenges and open up new applications.

Advances in Magnetic Materials

- Next-Generation NdFeB Magnets: Research is underway to develop NdFeB magnets with improved thermal stability and corrosion resistance. Innovations in material science, including the development of advanced coatings and alloy modifications, are expected to extend the operational life of these magnets in harsh environments.

- Hybrid Magnet Systems: Combining the strengths of NdFeB and SmCo magnets could lead to hybrid systems that offer both high magnetic strength and exceptional thermal stability. Such systems could be tailored to specific applications, balancing performance with durability.

Integration with Smart Systems

- Real-Time Control: Advances in sensor technology and real-time data processing are paving the way for intelligent systems that can continuously monitor and adjust the magnetic field in response to changes in the flow and temperature of the liquid metal.

- Adaptive Manufacturing: In manufacturing settings, adaptive control systems using magnetic manipulation may allow for on-the-fly adjustments to processes such as welding, casting, and additive manufacturing, leading to higher quality and reduced waste.

Broader Applications

The principles of magnetic control are not limited to traditional metallurgical applications. Emerging areas include:

- Space and Aeronautics: In aerospace, the ability to manipulate liquid metals could lead to new methods for in-situ resource utilization (ISRU) on other planets, where extracting and refining metals under low gravity conditions is a challenge.

- Renewable Energy Systems: Liquid metal batteries, which are being explored for grid-scale energy storage, could benefit from magnetic control to improve charge-discharge efficiency and longevity.

- Biomedical Engineering: Although still in the early stages, there is potential for magnetic manipulation of biocompatible liquid metals in medical applications, such as targeted drug delivery or innovative cooling techniques for hyperthermia treatments.

Case Studies

To illustrate the practical implications, consider two case studies that highlight successful applications of magnetic control in industrial settings.

Case Study 1: Electromagnetic Stirring in High-Performance Casting

An advanced manufacturing facility sought to improve the consistency of a high-strength aluminum alloy used in aerospace components. By integrating a system of NdFeB magnets into the casting mold, the engineers were able to generate controlled electromagnetic stirring. The resulting effects included:

Refined Microstructure: The stirring action produced a finer, more uniform grain structure, enhancing the alloy’s mechanical properties.

Reduced Defects: Improved flow and reduced turbulence led to fewer casting defects, thereby increasing the yield of high-quality components.

Operational Efficiency: The non-contact stirring method reduced wear on mechanical components, lowering maintenance costs over time.

Case Study 2: Liquid Metal Cooling in Nuclear Reactor Prototypes

In the development of next-generation nuclear reactors, efficient and reliable cooling is paramount. A research team employed SmCo magnets in a prototype liquid metal cooling system using molten sodium as the coolant. Key outcomes included:

- Enhanced Heat Transfer: The magnetic field optimized the coolant flow, ensuring more uniform temperature distribution across the reactor core.

- Increased Safety Margins: The precise control over coolant flow helped mitigate the risk of localized overheating, a critical safety consideration in reactor design.

- Scalability: The success of the prototype has paved the way for further research into scaling the technology for commercial reactor designs, with the potential to improve reactor efficiency and lifespan.

Conclusion

The interaction between magnetic fields and liquid metals presents a rich field of study with significant practical applications. From the detailed understanding provided by magnetohydrodynamics (MHD) to the tailored applications in casting, cooling, and transport, magnets—especially NdFeB magnets and SmCo magnets—are central to advancing modern industrial processes. The ability to control the flow, solidification, and heat transfer of liquid metals opens up numerous opportunities for innovation across sectors such as aerospace, energy, and advanced manufacturing.

While challenges such as corrosion, energy consumption, and system complexity persist, ongoing research is rapidly addressing these issues. Future advances in magnetic materials and adaptive control systems promise to further revolutionize the way we handle and process liquid metals. With the development of hybrid magnet systems and smarter integration with real-time monitoring, the next generation of industrial processes will likely see even greater improvements in efficiency, safety, and product quality.

In summary, the influence of magnets on liquid metals is not only a fascinating topic in theoretical physics but also a cornerstone of many cutting-edge industrial applications. As research continues and technologies evolve, the benefits of harnessing magnetic fields to control liquid metals will undoubtedly expand, driving innovation in fields that rely on the precision and power of magnetic manipulation.