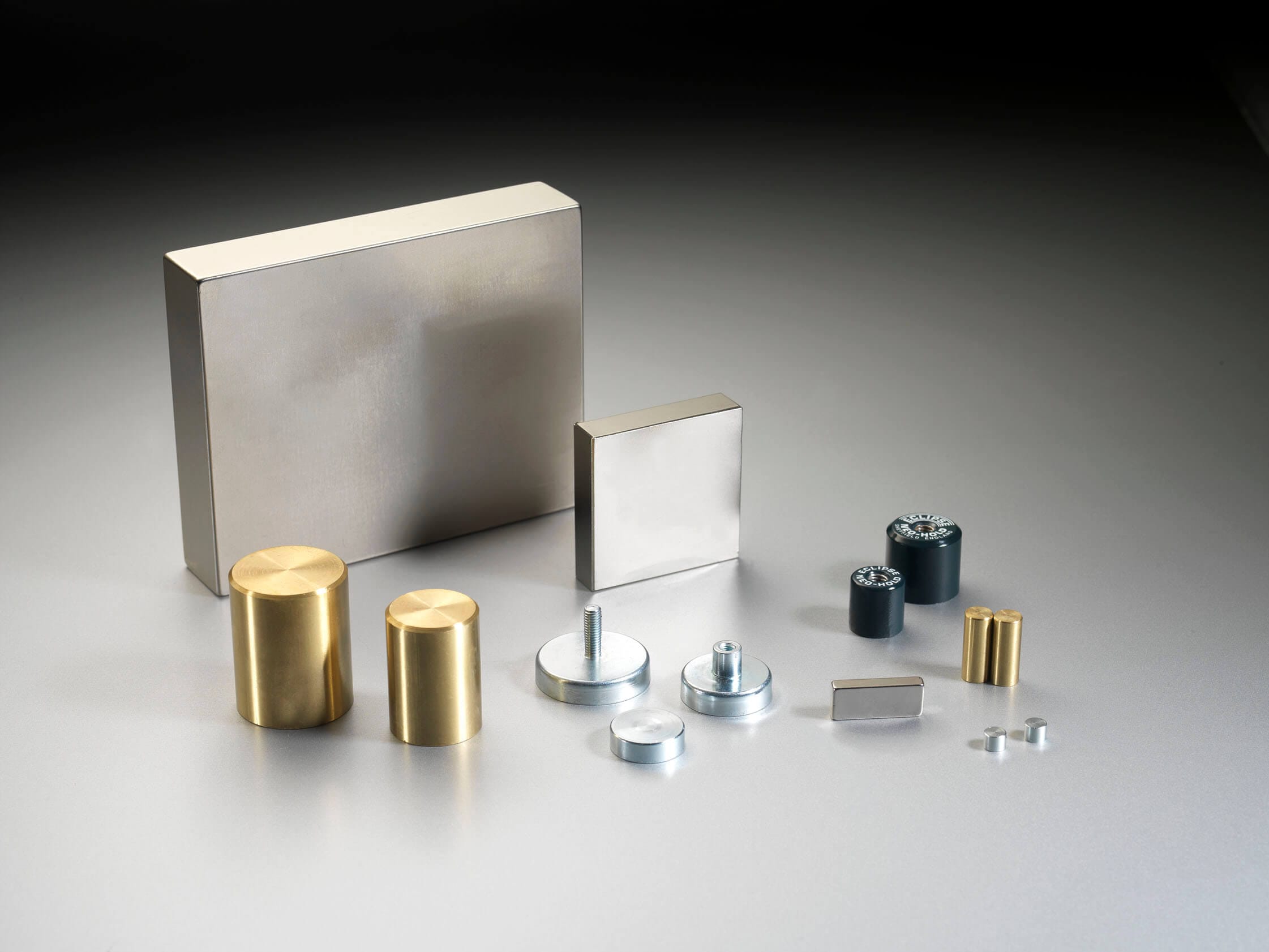

NdFeB (neodymium-iron-boron) magnets, renowned for their exceptional magnetic strength, are widely used across industries such as electronics, automotive, aerospace, and renewable energy. The performance of these magnets is influenced by a variety of factors, including composition, temperature, and geometrical dimensions. Among these dimensions, thickness plays a critical role in determining the magnetic properties of NdFeB magnets. This article explores the intricate relationship between thickness and the magnetic characteristics of these powerful magnets, shedding light on their practical implications.

Understanding the Magnetic Properties of NdFeB Magnets

To fully grasp the influence of thickness, it is essential to first understand the magnetic properties that define NdFeB magnets. These magnets are categorized as rare-earth magnets and exhibit remarkable attributes such as high magnetic remanence, high coercivity, and excellent energy density.

- Magnetic Remanence (Br): This refers to the magnet’s ability to retain magnetization when the external magnetic field is removed.

- Coercivity (Hc): This indicates the magnet’s resistance to demagnetization.

- Maximum Energy Product (BHmax): This is a measure of the magnet’s overall energy storage capacity, representing the density of magnetic energy available for application.

The magnetic properties of NdFeB magnets are highly sensitive to their material composition, operating temperature, and physical dimensions, including thickness. By examining the role of thickness, we can better predict and tailor these magnets for specific applications.

Influence of Thickness on Magnetic Strength

Thickness directly affects the magnetic flux density and, consequently, the overall performance of an NdFeB magnet. In magnets, flux density refers to the measure of the magnetic field’s strength and distribution. When the thickness of an NdFeB magnet increases, the path for the magnetic field expands, resulting in changes to its magnetic behavior.

Flux Density Distribution

In thinner magnets, the shorter magnetic circuit path often leads to a concentration of flux lines near the magnet’s surface. This creates a higher surface field strength but may limit the depth of penetration for the magnetic field. Conversely, increasing the thickness extends the flux path, enhancing the depth of penetration and allowing for a more uniform distribution of the magnetic field. This makes thicker NdFeB magnets preferable in applications requiring deeper field penetration, such as sensors or actuators.

Saturation Effects

Magnetic saturation occurs when a magnet reaches its maximum potential for magnetization. Thickness plays a role in determining whether a magnet can achieve full saturation. Thin NdFeB magnets may not allow enough material volume to support the maximum achievable magnetization, potentially reducing the available energy product. Thicker magnets, by contrast, provide sufficient material volume for the alignment of magnetic domains, leading to enhanced magnetic performance.

Coercivity and Demagnetization Resistance

Coercivity is a critical property for NdFeB magnets used in challenging environments where demagnetizing forces are present. The thickness of the magnet influences its ability to withstand such forces.

Thinner magnets are more susceptible to external demagnetizing influences, such as high temperatures or opposing magnetic fields. The reduced material volume limits their capacity to resist such forces effectively. On the other hand, increasing the thickness enhances the magnet’s demagnetization resistance by providing a more robust structure that can maintain the alignment of magnetic domains. This makes thicker NdFeB magnets suitable for high-stress applications, including motors and generators.

Thickness and Energy Product Optimization

The maximum energy product (BHmax) represents the point at which a magnet achieves optimal efficiency in converting magnetic energy into useful work. This parameter is closely tied to the magnet’s geometry, including its thickness.

When designing an NdFeB magnet, optimizing its thickness is crucial for achieving the desired energy density. Excessive thickness may lead to material waste without significant gains in energy product, while insufficient thickness may compromise the magnet’s performance. Computational modeling and empirical testing are often employed to identify the ideal thickness for specific applications, balancing material efficiency and magnetic output.

Thermal Stability and Thickness Dependency

Temperature is a significant factor in the performance of NdFeB magnets, and thickness influences their thermal stability. Thinner magnets are more prone to temperature-induced demagnetization due to their reduced ability to dissipate heat. The smaller material volume in thin magnets results in faster temperature changes, which can compromise their magnetic properties.

Thicker NdFeB magnets, by contrast, have a greater capacity to distribute heat, maintaining more stable magnetic performance under varying temperature conditions. This advantage makes thicker magnets ideal for high-temperature environments, such as electric vehicle motors and aerospace systems.

Applications and Practical Considerations

The relationship between thickness and magnetic properties informs the selection of NdFeB magnets across diverse applications. Engineers and designers must consider how thickness impacts not only the magnet’s performance but also its integration into the final product.

- Miniaturized Devices: Thin NdFeB magnets are preferred for compact electronic devices like smartphones and wearable technology, where space is limited, and surface magnetic field strength is prioritized.

- Industrial Equipment: Applications requiring high demagnetization resistance, such as industrial motors or wind turbines, benefit from thicker magnets that ensure durability and consistent performance under stress.

- Medical Technology: In medical imaging systems like MRI machines, the uniform field distribution offered by thicker NdFeB magnets is advantageous for achieving precise diagnostic results.

Balancing Performance and Material Cost

One of the challenges in leveraging the relationship between thickness and magnetic properties lies in balancing performance requirements with material cost. NdFeB magnets are made from rare-earth materials, which are expensive and subject to supply chain fluctuations. Optimizing thickness helps minimize material usage without compromising performance, making the magnets more cost-effective for large-scale production.

Advanced Manufacturing Techniques

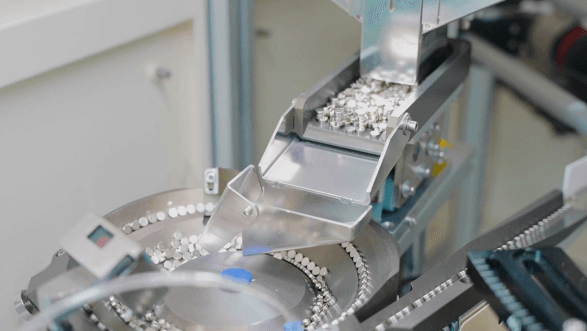

Modern manufacturing techniques, such as powder metallurgy and additive manufacturing, allow for precise control over the dimensions and properties of NdFeB magnets. These methods enable the production of magnets with customized thicknesses to meet specific application requirements, further enhancing their efficiency and affordability.

Future Trends and Research Directions

As industries continue to demand higher-performing magnets, research into the relationship between thickness and magnetic properties remains a priority. Emerging trends include:

- Nanostructured Magnets: Advances in nanotechnology are enabling the development of NdFeB magnets with precisely engineered microstructures, optimizing thickness for improved performance.

- Hybrid Designs: Combining NdFeB magnets with other materials in layered or composite structures allows for the fine-tuning of thickness and magnetic properties to suit specialized applications.

- Sustainable Materials: Efforts to reduce reliance on rare-earth elements are driving the exploration of alternative materials and alloys, which may influence the role of thickness in future magnet designs.

Conclusion

The thickness of NdFeB magnets plays a pivotal role in shaping their magnetic properties, affecting everything from flux density distribution to thermal stability and demagnetization resistance. Understanding and optimizing this relationship is essential for designing magnets that meet the diverse demands of modern technology. By carefully considering thickness during the design and manufacturing processes, engineers can unlock the full potential of NdFeB magnets while balancing performance, cost, and sustainability.