The industrial world is rife with innovations, each designed to streamline processes and enhance efficiency. One such innovation that has revolutionized the field of material handling is the permanent magnetic lifter. Central to these powerful tools are NdFeB magnets, also known as neodymium magnets. This article delves into the pivotal role of NdFeB magnets in permanent magnetic lifters, explaining how they work, why they are indispensable, and what makes custom options like Custom Neodymium Magnets and Custom SmCo Magnets so valuable in various applications.

Understanding NdFeB Magnets and Their Importance

Neodymium magnets, or NdFeB magnets, are a type of rare earth magnet made from an alloy of neodymium, iron, and boron. These magnets are known for their exceptional magnetic properties, including high remanence and coercivity, which make them the strongest type of permanent magnets available today. NdFeB magnets are crucial in numerous industrial applications, particularly in the manufacturing of permanent magnetic lifters.

Properties of NdFeB Magnets

High Magnetic Strength: NdFeB magnets possess a very high magnetic strength, which allows them to lift heavy loads with minimal effort. This makes them ideal for applications in industries like construction, shipbuilding, and steel manufacturing, where large and heavy metal objects are common.

Resistance to Demagnetization: NdFeB magnets have high coercivity, meaning they resist demagnetization, maintaining their magnetic properties over time even under adverse conditions.

Compact Size: The strong magnetic force of NdFeB magnets means they can be smaller in size yet perform the same function as larger magnets made from other materials. This compactness is a significant advantage in designing and manufacturing magnetic lifters, where space and weight constraints often play a critical role.

Versatility and Customization: NdFeB magnets can be manufactured in various shapes, sizes, and grades, making them suitable for a wide range of applications. Custom Neodymium Magnets can be tailored to specific requirements, enhancing their utility in specialized lifting applications.

How Do Permanent Magnetic Lifters Work?

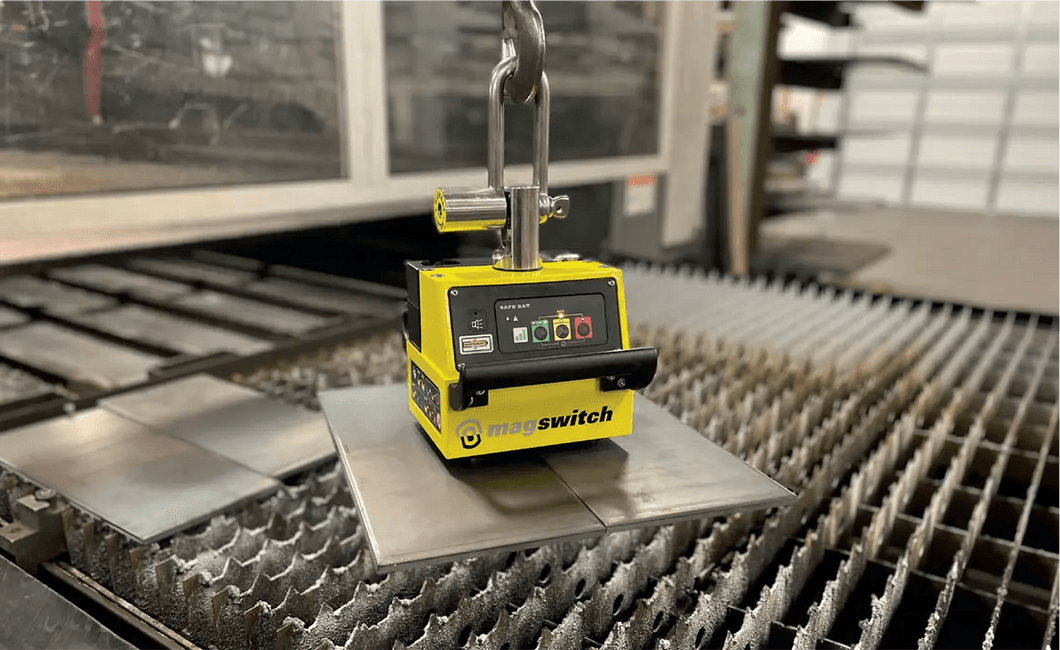

Permanent magnetic lifters are ingenious devices that utilize the power of magnets to lift and move heavy ferrous materials without the need for external power sources such as electricity. The core component of these lifters is the NdFeB magnet, renowned for its exceptional magnetic strength and reliability. But how exactly do these lifters operate?

At the heart of every permanent magnetic lifter is a carefully engineered magnetic system composed of NdFeB magnets. These magnets are arranged to create a focused and intense magnetic field. The lifter typically includes a handle or lever mechanism that the operator can use to control the magnetic force. When the lifter is placed on a ferrous material, such as a steel plate or metal beam, the operator pulls the handle, which aligns the magnetic field lines with the material, generating a powerful magnetic attraction.

This attraction force is strong enough to securely grip the material, allowing the operator to lift and move it with ease. The handle mechanism often includes safety features that lock the magnetic system in place, preventing accidental release of the load. This ensures that the lifted material remains securely attached during transport, enhancing both safety and efficiency.

To release the load, the operator simply reverses the handle’s action. This reorients the magnetic field away from the material, reducing the magnetic force and allowing the object to be safely detached. The precision and control offered by this mechanism make permanent magnetic lifters a reliable choice for various industrial applications, from construction and manufacturing to shipbuilding and logistics.

Permanent magnetic lifters, powered by the impressive NdFeB magnets, offer a versatile and efficient solution for material handling, underscoring the crucial role these magnets play in modern industry.

Components of a Permanent Magnetic Lifter

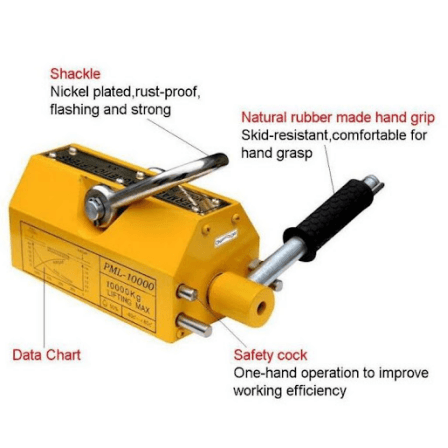

Magnetic System: At the heart of a permanent magnetic lifter is the magnetic system, typically consisting of NdFeB magnets arranged to create a strong and focused magnetic field. This system is designed to maximize the lifting capacity while minimizing the size and weight of the lifter.

Lifting Mechanism: The lifting mechanism includes a handle or lever that the operator uses to engage and disengage the magnetic force. When the lifter is placed on a ferrous material and the handle is activated, the magnetic field lines penetrate the material, creating a strong attraction force that lifts the object.

Safety Features: Modern permanent magnetic lifters often include safety features such as locking mechanisms to prevent accidental release of the load, as well as indicators that show the status of the magnetic system.

Operating Principle

The operation of a permanent magnetic lifter involves several key steps:

Positioning: The lifter is positioned on the surface of the ferrous material to be lifted.

Activation: The operator activates the magnetic system by pulling a handle or lever, which aligns the magnetic field lines with the material. This action significantly increases the magnetic force, allowing the lifter to securely grip the load.

Lifting: Once the magnetic force is engaged, the material can be lifted and moved as needed. The strength of NdFeB magnets ensures that the load remains secure during transport.

Deactivation: To release the load, the operator reverses the handle or lever action, which reorients the magnetic field lines away from the material, reducing the magnetic force and allowing the load to be safely detached.

Applications of NdFeB Magnets in Permanent Magnetic Lifters

Permanent magnetic lifters are widely used across various industries due to their efficiency and reliability. The use of NdFeB magnets in these lifters enhances their performance, making them suitable for a broad range of applications:

Manufacturing and Assembly: In manufacturing plants, permanent magnetic lifters are used to lift and position heavy metal parts during assembly processes. This application is particularly common in the automotive and aerospace industries, where precision and safety are paramount.

Shipbuilding: The shipbuilding industry often deals with large steel plates and components that are cumbersome to move manually. Permanent magnetic lifters provide a practical solution, enabling workers to lift and position these materials with ease.

Construction: Construction sites frequently involve the handling of heavy metal beams, pipes, and other components. Permanent magnetic lifters facilitate the safe and efficient movement of these materials, reducing the need for manual labor and minimizing the risk of injury.

Steel Production and Processing: In steel mills and processing plants, permanent magnetic lifters are used to handle raw materials, finished products, and scrap metal. The strength of NdFeB magnets ensures that even heavy loads are securely gripped, improving operational efficiency.

Warehousing and Logistics: Permanent magnetic lifters are also useful in warehouses and logistics centers, where they help in the loading and unloading of metal goods. Their ability to lift without the need for external power makes them a versatile tool in various logistical operations.

Customization and Specialized Applications

The versatility of NdFeB magnets allows for extensive customization in the design and manufacture of permanent magnetic lifters. This customization is crucial in meeting the specific needs of different industries and applications.

Custom Neodymium Magnets and Custom SmCo Magnets

Custom Neodymium Magnets can be designed to meet specific lifting requirements, such as lifting capacity, size constraints, and environmental conditions. For example, magnets with higher coercivity can be used in environments with high temperatures or exposure to external magnetic fields. Similarly, Custom SmCo Magnets, which are another type of rare earth magnet, can be used in applications requiring high resistance to corrosion and demagnetization.

Customization extends to the shape and configuration of the magnets within the lifter. Different applications may require magnets arranged in a particular pattern to optimize the lifting force or to focus the magnetic field on a specific area of the load. This level of customization ensures that the lifter performs optimally, enhancing efficiency and safety in material handling operations.

Importance of Quality and Precision

The performance of permanent magnetic lifters depends significantly on the quality and precision of the NdFeB magnets used. High-quality magnets ensure consistent performance and longevity, while precise manufacturing tolerances ensure that the magnetic system operates efficiently. This is particularly important in applications where safety and reliability are critical, such as in aerospace or heavy industrial settings.

Advantages of NdFeB Magnets in Permanent Magnetic Lifters

The use of NdFeB magnets in permanent magnetic lifters offers several advantages:

High Efficiency: The strong magnetic force of NdFeB magnets allows for the efficient lifting of heavy loads, reducing the need for manual labor and minimizing handling time.

Safety: NdFeB magnets provide a secure grip on ferrous materials, minimizing the risk of load slippage or accidents. Additionally, the ability to deactivate the magnetic force provides a reliable method for safely releasing loads.

Cost-Effectiveness: Permanent magnetic lifters do not require electricity to operate, reducing operational costs and minimizing the need for maintenance. The durability of NdFeB magnets also means that the lifters have a long service life.

Versatility: The customization options available with NdFeB magnets make permanent magnetic lifters suitable for a wide range of applications. Whether for lifting large steel plates or handling delicate components, these lifters can be tailored to meet specific needs.

Environmental Benefits: Permanent magnetic lifters are environmentally friendly, as they do not produce emissions or require fuel. This makes them an attractive option for companies looking to reduce their carbon footprint.

Conclusion

NdFeB magnets play a crucial role in the performance and efficiency of permanent magnetic lifters. Their high magnetic strength, resistance to demagnetization, and compact size make them ideal for lifting applications in various industries. The ability to customize these magnets, as seen with options like Custom Neodymium Magnets and Custom SmCo Magnets, further enhances their versatility and utility. As industries continue to seek efficient and reliable solutions for material handling, the importance of NdFeB magnets in permanent magnetic lifters is set to grow, solidifying their position as a key component in modern industrial processes.

For businesses looking to optimize their lifting operations, investing in high-quality NdFeB magnets and customized magnetic lifters is a strategic decision that promises long-term benefits in terms of efficiency, safety, and cost savings.