Introduction

Imagine a world without magnets: no electric motors, no data storage, no efficient power generation. Magnets are the unseen force driving countless technologies that shape our daily lives. From the speakers in our smartphones to the intricate mechanisms in medical devices, magnets are indispensable. Among the various types of magnets, neodymium and ceramic magnets stand out due to their widespread applications and unique properties. Understanding the differences between these two can help businesses and innovators make informed decisions, optimizing both performance and cost-effectiveness in their projects.

Understanding Neodymium Magnets

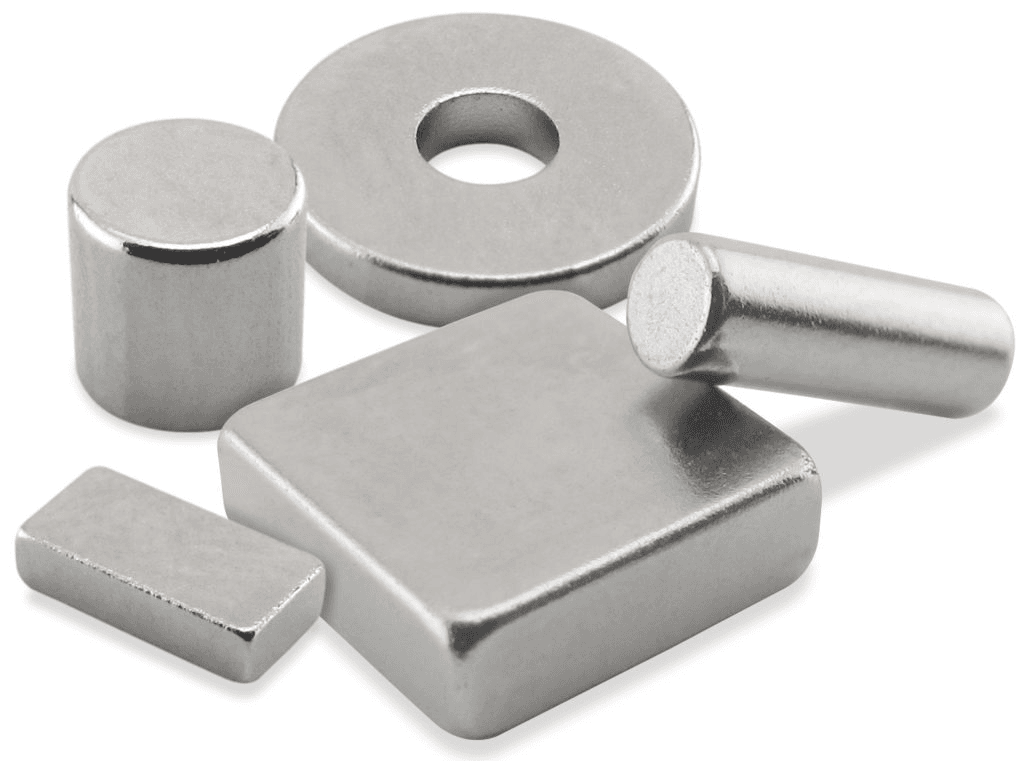

Definition and Composition

Neodymium magnets, also known as NdFeB magnets, are the strongest type of permanent magnet commercially available. They are composed of an alloy of neodymium, iron, and boron (NdFeB), which gives them their superior magnetic properties. This composition enables neodymium magnets to generate significantly higher magnetic fields than other types of magnets, making them highly sought after in various high-tech applications.

History and Development

The journey of neodymium magnets began in the early 1980s when General Motors and Sumitomo Special Metals developed the NdFeB alloy independently. The invention of neodymium magnets marked a breakthrough in magnetic materials, as it provided a more powerful and cost-effective alternative to samarium-cobalt magnets. Over the years, advancements in manufacturing processes have further enhanced the performance and reduced the cost of neodymium magnets, solidifying their position as a cornerstone in modern technology.

Properties and Characteristics

Neodymium magnets are renowned for their exceptional magnetic strength. They have a high remanence, which is the magnetization left behind in the absence of an external magnetic field, and a high coercivity, which is the resistance to demagnetization. These properties make neodymium magnets incredibly powerful and reliable. However, they are also brittle and prone to corrosion, requiring protective coatings such as nickel, zinc, or epoxy to enhance their durability.

Common Applications

The applications of neodymium magnets are diverse and span numerous industries. In electronics, they are used in hard drives, mobile phones, and audio equipment due to their compact size and strong magnetic fields. In the medical field, neodymium magnets are essential components of MRI machines, which rely on their powerful magnetic fields for imaging. Additionally, neodymium magnets play a crucial role in the renewable energy sector, particularly in wind turbines and electric vehicle motors, where their efficiency and strength contribute to better performance and energy savings.

Understanding Ceramic Magnets

Definition and Composition

Ceramic magnets, also known as ferrite magnets, are composed of iron oxide mixed with either barium or strontium carbonate. These magnets are known for their affordability and versatility. Despite being less powerful than neodymium magnets, ceramic magnets offer sufficient magnetic strength for many everyday applications and are highly resistant to corrosion.

History and Development

Ceramic magnets were developed in the 1950s as an economical alternative to metallic magnets. Their production involves a simple and cost-effective process of pressing and sintering, which allows for mass production at a lower cost. Over the decades, ceramic magnets have become the most widely used type of magnet due to their affordability and adequate performance for a wide range of applications.

Properties and Characteristics

While ceramic magnets do not match the magnetic strength of neodymium magnets, they are highly valued for their stability and resistance to demagnetization. They are also non-conductive, making them suitable for certain electrical applications. Ceramic magnets are hard and brittle, similar to neodymium magnets, but their inherent resistance to corrosion eliminates the need for additional protective coatings.

Common Applications

Ceramic magnets are ubiquitous in everyday life. They are commonly found in household items such as refrigerator magnets and toys. In the automotive industry, ceramic magnets are used in magnetos, which are components in ignition systems. Industrial applications include magnetic separators and lifting magnets, where their moderate strength and cost-effectiveness make them an ideal choice.

Comparative Analysis of Neodymium and Ceramic Magnets

Magnetic Strength

The primary distinction between neodymium and ceramic magnets lies in their magnetic strength. Neodymium magnets are significantly stronger than ceramic magnets, with magnetic fields up to ten times more powerful. This superior strength makes neodymium magnets the preferred choice for applications requiring high magnetic performance, such as electric motors and medical devices. In contrast, ceramic magnets, while weaker, provide adequate strength for less demanding applications and offer a more cost-effective solution.

Temperature Resistance

Temperature resistance is another critical factor when choosing between neodymium and ceramic magnets. Neodymium magnets have a lower Curie temperature, meaning they can lose their magnetic properties at relatively lower temperatures. However, advancements in technology have led to the development of high-temperature neodymium magnets that can operate in more extreme conditions. Ceramic magnets, on the other hand, excel in temperature resistance and maintain their magnetic properties over a wider temperature range, making them suitable for applications exposed to varying temperatures.

Cost and Availability

Cost is a significant consideration in the choice of magnets. Neodymium magnets, due to their complex manufacturing process and the rarity of neodymium, are more expensive than ceramic magnets. The price of neodymium magnets can also fluctuate based on the availability of rare earth elements. Ceramic magnets, being made from more common materials and simpler manufacturing processes, are considerably cheaper. This affordability makes ceramic magnets an attractive option for applications where cost is a primary concern.

Durability and Lifespan

Both neodymium and ceramic magnets are brittle, but they differ in their resistance to corrosion. Neodymium magnets are prone to oxidation and require protective coatings to prevent rust and extend their lifespan. Ceramic magnets, however, are naturally resistant to corrosion, giving them an edge in durability, especially in environments prone to moisture and chemical exposure.

Weight and Size Considerations

Neodymium magnets are denser and therefore heavier than ceramic magnets of the same size. This higher density allows neodymium magnets to produce stronger magnetic fields in smaller volumes, which is beneficial for applications where space and weight are limited, such as in electronic devices and compact motors. Ceramic magnets, being lighter and larger for the same magnetic strength, are more suited for applications where size and weight are less critical.

Choosing the Right Magnet for Your Needs

Assessing Application Requirements

The first step in choosing the right magnet is to assess the specific requirements of the application. For high-performance needs, such as in electric motors or medical devices, neodymium magnets are likely the best choice due to their superior strength. For applications that do not require intense magnetic fields but prioritize cost and corrosion resistance, ceramic magnets are an ideal solution.

Budget Constraints

Budget plays a crucial role in the decision-making process. If the application can accommodate the higher cost of neodymium magnets, the investment will often be justified by their performance benefits. However, for applications with tight budget constraints, ceramic magnets offer a practical and economical alternative without compromising on essential functionality.

Long-term Considerations

When evaluating long-term considerations, factors such as lifespan, maintenance, and environmental exposure must be taken into account. Neodymium magnets, with their need for protective coatings, may require more maintenance in corrosive environments, whereas ceramic magnets, with their inherent corrosion resistance, offer a low-maintenance solution.

Case Studies and Real-world Examples

Real-world examples can provide valuable insights into the practical applications of neodymium and ceramic magnets. For instance, electric vehicle manufacturers favor neodymium magnets for their motors due to their high efficiency and power density, which contribute to better vehicle performance and range. On the other hand, ceramic magnets are widely used in household appliances and automotive components, where their cost-effectiveness and adequate performance make them a preferred choice.

Conclusion

In summary, both neodymium and ceramic magnets have their unique strengths and weaknesses, making them suitable for different applications. Neodymium magnets offer unparalleled magnetic strength and compact size, making them ideal for high-performance and space-constrained applications. Ceramic magnets, while less powerful, provide a cost-effective and durable solution for a wide range of uses. Understanding the specific requirements of your application, considering budget constraints, and evaluating long-term maintenance needs are crucial steps in choosing the right magnet.

Making an informed choice between neodymium and ceramic magnets can significantly impact the efficiency, cost, and durability of your products. As you navigate this decision, consulting with experts and leveraging real-world case studies can provide additional guidance tailored to your specific needs. At MagnetsTek, we are dedicated to helping you find the perfect magnetic solution, ensuring optimal performance and satisfaction for your projects.