Introduction

Have you ever experienced the frustration of cabinet doors that just won’t stay shut? Whether it’s in your kitchen, office, or workshop, cabinet doors that swing open or don’t close securely can be a constant annoyance. Fortunately, there’s a simple and effective solution: strong cabinet magnets. These magnets can ensure that your cabinet doors remain firmly closed, providing both convenience and peace of mind. In this article, we’ll explore the top kinds of strong cabinet magnets and guide you on where to get them, so you can keep your spaces organized and efficient.

Understanding Cabinet Magnets

Definition and Function

Cabinet magnets are small but powerful magnets designed to hold cabinet doors closed. They are typically installed inside the cabinet frame and door, creating a secure magnetic lock when the door is closed. These magnets come in various shapes, sizes, and strengths, depending on the specific needs of the cabinet.

Importance of Strength

The strength of a cabinet magnet is crucial. Weak magnets may not provide a secure hold, especially for heavier doors or those that are frequently used. Strong cabinet magnets ensure that doors stay closed, preventing accidental openings and keeping contents safe and secure. This is particularly important in environments where safety and cleanliness are paramount, such as kitchens and medical facilities.

Common Uses

Strong cabinet magnets are used in a wide range of applications. In homes, they are commonly found in kitchen cabinets, bathroom vanities, and closet doors. In industrial settings, they secure storage units, tool cabinets, and machinery access panels. They are also used in office furniture, such as filing cabinets and storage lockers, where secure closure is necessary.

Types of Strong Cabinet Magnets

Neodymium Magnets

Neodymium magnets, also known as NdFeB magnets, are among the strongest permanent magnets available. They are made from an alloy of neodymium, iron, and boron, providing exceptional strength and durability.

Properties: Neodymium magnets are known for their high magnetic strength, making them ideal for heavy-duty applications. They are also resistant to demagnetization and have a long lifespan.

Common Applications: These magnets are perfect for kitchen cabinets, where a strong hold is needed to keep doors securely closed. They are also used in heavy-duty storage units and industrial cabinets.

Samarium Cobalt Magnets

Samarium cobalt (SmCo) magnets are another type of rare earth magnet known for their strength and resistance to extreme temperatures and corrosion.

Properties: SmCo magnets are highly resistant to temperature changes and corrosion, making them suitable for harsh environments. They offer high magnetic strength and stability.

Common Applications: These magnets are ideal for industrial and outdoor cabinets that are exposed to varying temperatures and weather conditions. They are also used in medical and scientific equipment where precision and reliability are essential.

Alnico Magnets

Alnico magnets are made from an alloy of aluminum, nickel, and cobalt. They have been used for many years in various applications due to their stability and strength.

Properties: Alnico magnets produce a strong magnetic field and have excellent temperature stability. They are less prone to corrosion compared to other magnets.

Common Applications: These magnets are often used in retro or vintage-style cabinets, as they can be easily molded into different shapes and provide a classic look. They are also used in musical instruments and other specialized equipment.

Ferrite (Ceramic) Magnets

Ferrite magnets, also known as ceramic magnets, are made from a mixture of iron oxide and ceramic materials. They are widely used due to their cost-effectiveness and moderate strength.

Properties:Ferrite magnets are inexpensive, moderately strong, and resistant to corrosion. They work well in a variety of temperatures.

Common Applications: These magnets are commonly used in general household cabinets, such as those in kitchens and bathrooms. They are also found in less demanding industrial applications.

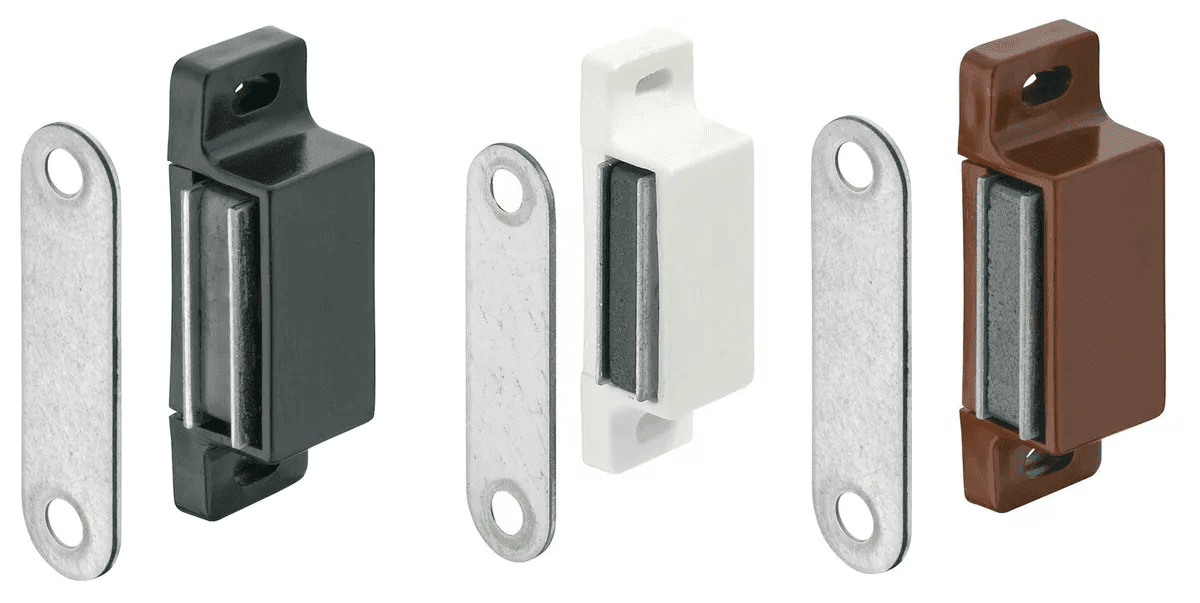

Magnetic Assemblies

Magnetic assemblies combine magnets with other materials, such as steel or plastic, to enhance their functionality and ease of installation.

Properties: These assemblies can be customized for specific uses, providing both strong magnetic hold and ease of installation. They often include features such as mounting brackets or adhesive backing.

Common Applications: Magnetic assemblies are used in specialized cabinetry, complex locking mechanisms, and applications where a simple magnet might not suffice.

Selecting the Right Magnet for Your Cabinets

Factors to Consider

When choosing the right magnet for your cabinet doors, consider the following factors:

– Weight of the Cabinet Door: Heavier doors require stronger magnets to ensure they stay closed.

– Frequency of Use: Frequently used doors may need more robust magnets to withstand repeated opening and closing.

– Environmental Conditions: Consider humidity, temperature, and exposure to corrosive elements. For example, kitchens and bathrooms might require magnets resistant to moisture.

– Aesthetic Preferences: The appearance of the magnet, whether visible or hidden, can affect your choice, especially for cabinets in living spaces.

Custom vs. Standard Magnets

– Benefits of Custom Magnets: Custom magnets can be tailored to specific dimensions, strengths, and finishes to meet unique requirements. They are ideal for bespoke furniture or specialized industrial applications.

– When to Opt for Standard Magnets: Standard magnets are readily available and often sufficient for most household and light industrial uses. They are cost-effective and easy to replace.

Installation Tips for Cabinet Magnets

Preparation

Before installing cabinet magnets, gather the necessary tools and take safety precautions:

– Tools Needed: Drill, screws, screwdriver, measuring tape, pencil, and safety glasses.

– Safety Precautions: Wear safety glasses to protect your eyes from debris, and ensure the work area is well-ventilated.

Step-by-Step Guide

1. Measuring and Marking Placement: Measure the placement of the magnet on both the cabinet frame and the door. Mark the positions with a pencil.

2. Drilling and Securing Magnets: Drill pilot holes at the marked positions. Secure the magnet to the door and the corresponding metal plate or magnet to the frame using screws.

3. Testing the Installation: Close the cabinet door to test the magnet’s hold. Adjust as necessary to ensure a secure closure.

Troubleshooting Common Issues

– Misalignment: If the magnet and metal plate are not aligned, the door may not close properly. Re-measure and adjust the placement.

– Insufficient Holding Strength: If the magnet is not strong enough, consider replacing it with a stronger one or adding additional magnets for extra hold.

Where to Buy Strong Cabinet Magnets

Top Manufacturers and Suppliers

– MagnetsTek: A leading manufacturer and supplier of custom and standard magnets. MagnetsTek offers a wide range of high-quality magnets suitable for various applications.

– Other Reliable Suppliers: Companies like K&J Magnetics and Apex Magnets are also known for their quality products and customer service.

Online Marketplaces

– Amazon: Offers a vast selection of magnets, including user reviews and ratings. However, product quality can vary.

– Alibaba: Ideal for bulk purchases and custom orders. Be sure to check supplier ratings and reviews to ensure reliability.

Specialty Stores

– Benefits: Purchasing from specialized hardware or magnet stores ensures access to knowledgeable staff and high-quality products.

– Examples: Local hardware stores or specialized magnet retailers often carry a range of options suitable for various applications.

Direct from Manufacturer

– Advantages: Buying directly from manufacturers like MagnetsTek provides access to custom solutions, bulk discounts, and expert advice. This is particularly beneficial for large-scale or specialized projects.

Case Studies and Testimonials

Real-life Examples

– Residential Use: A homeowner installed neodymium magnets in their kitchen cabinets, ensuring that even heavy doors stayed securely closed, enhancing the kitchen’s functionality and safety.

– Commercial Use: An industrial facility used samarium cobalt magnets to secure outdoor storage units, withstanding harsh weather conditions and providing reliable security.

Expert Opinions

– Cabinet Makers: Professional cabinet makers often recommend using high-quality neodymium magnets for their strength and durability, ensuring customer satisfaction and long-term reliability.

– Industrial Designers: Experts in industrial design highlight the importance of choosing the right type of magnet for specific applications, emphasizing factors like temperature resistance and corrosion.

Customer Testimonials

– Satisfied Customers: Numerous customers have shared positive experiences, praising the ease of installation and the improved functionality of their cabinets after using strong magnets. They often highlight the significant difference it makes in their daily routines.

Conclusion

Recap of Key Points

Choosing the right cabinet magnet is crucial for ensuring secure closure and ease of use. We’ve explored various types of strong cabinet magnets, including neodymium, samarium cobalt, alnico, and ferrite magnets, as well as magnetic assemblies. Each type has its unique properties and applications, making it essential to consider factors like weight, frequency of use, and environmental conditions when making your selection.

Final Thoughts

Strong cabinet magnets offer a simple yet effective solution to the common problem of cabinet doors not staying closed. By understanding the different types and selecting the right magnet for your needs, you can enhance the functionality and aesthetics of your cabinets, whether in a residential or industrial setting.