Introduction

In the fast-paced world of modern manufacturing, the materials we use can make all the difference. Imagine a material that combines strength, versatility, and magnetic properties, opening a realm of possibilities across various industries. Enter magnetic steel sheeting – an unsung hero that has become indispensable in contemporary production lines. This article delves into the top ten uses of magnetic steel sheeting in modern manufacturing, showcasing its transformative impact and why it’s a cornerstone in today’s industrial landscape.

What is Magnetic Steel Sheeting?

Magnetic steel sheeting is a type of steel that exhibits strong magnetic properties, making it ideal for applications that require magnetism. It is typically composed of iron with added carbon and other elements to enhance its strength and durability. The magnetic properties arise from the alignment of the material’s internal structure, which allows it to attract and hold onto magnetic fields.

Magnetic steel sheeting is known for its robustness and versatility. It can be easily fabricated into different shapes and sizes, making it suitable for a wide range of applications. Its unique combination of mechanical and magnetic properties makes it a valuable resource in various sectors of manufacturing.

History and Development

The history of magnetic steel sheeting dates back to the early 20th century when scientists first began exploring the magnetic properties of different metals and alloys. Over the years, significant advancements in metallurgical techniques and materials science have led to the development of high-performance magnetic steels. These improvements have expanded the range of applications and enhanced the efficiency of manufacturing processes.

The evolution of magnetic steel sheeting is marked by innovations that have increased its strength, durability, and magnetic properties. Modern manufacturing techniques, such as cold rolling and heat treatment, have further optimized these materials for industrial use. Today, magnetic steel sheeting is an integral part of numerous high-tech and precision-based manufacturing operations.

Top 10 Uses for Magnetic Steel Sheeting in Modern Manufacturing

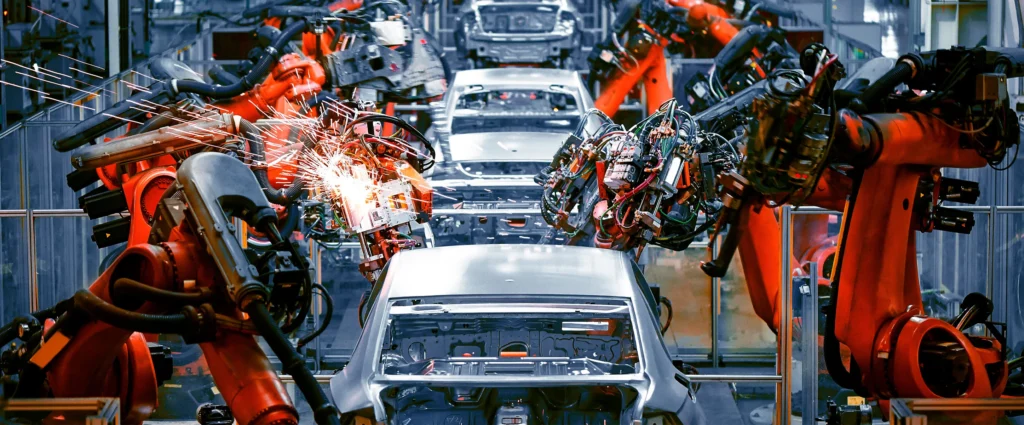

1. Automotive Industry

The automotive industry is a major consumer of magnetic steel sheeting. It is used extensively in car assembly lines for various applications. One of the primary uses is in the production of electric motors and generators. The magnetic properties of the steel enhance the performance and efficiency of these components, leading to better fuel efficiency and reduced emissions.

Additionally, magnetic steel sheeting is used in the construction of vehicle bodies and frames. Its strength and durability contribute to the safety and longevity of automobiles. The material’s magnetic properties are also leveraged in the manufacturing of sensors and actuators, which are critical for modern vehicle systems.

2. Electronics and Appliances

Magnetic steel sheeting plays a crucial role in the manufacturing of electronic devices and household appliances. In the electronics industry, it is used in the production of components such as transformers, inductors, and magnetic shielding. These applications rely on the material’s ability to efficiently conduct magnetic fields and reduce electromagnetic interference.

In household appliances, magnetic steel sheeting is used in the construction of motors, compressors, and other key components. Its durability ensures long-lasting performance, while its magnetic properties enhance the efficiency of electrical circuits. This makes appliances more reliable and energy-efficient.

3. Renewable Energy Sector

The renewable energy sector has embraced magnetic steel sheeting for its vital role in the production of wind turbines and solar panels. In wind turbines, the steel is used in the construction of generator components, where its magnetic properties are essential for converting mechanical energy into electrical energy. This contributes to the efficiency and reliability of wind energy systems.

Solar panels also benefit from the use of magnetic steel sheeting. The material is used in mounting systems and frames, providing the necessary strength and durability to withstand environmental conditions. Its magnetic properties are also utilized in tracking systems that enhance the efficiency of solar panels by optimizing their orientation to the sun.

4. Medical Equipment

In the medical field, precision and reliability are paramount. Magnetic steel sheeting is a critical material in the manufacturing of medical equipment, particularly in magnetic resonance imaging (MRI) machines. The steel’s magnetic properties are essential for creating the strong magnetic fields required for MRI imaging.

Additionally, magnetic steel sheeting is used in other medical devices and equipment, such as surgical instruments and diagnostic tools. Its durability and corrosion resistance ensure the longevity and safety of these devices, making it a trusted material in the healthcare industry.

5.Aerospace Industry

The aerospace industry demands materials that offer high strength-to-weight ratios, durability, and reliability. Magnetic steel sheeting meets these requirements and is used in the construction of aircraft components and systems. Its magnetic properties are particularly useful in applications such as electric motors and sensors.

In aircraft construction, magnetic steel sheeting is used for structural components, brackets, and frames. Its ability to withstand extreme conditions and resist corrosion makes it ideal for aerospace applications. The material’s magnetic properties also play a role in navigation and communication systems, contributing to the overall performance and safety of aircraft.

6. Construction Industry

Magnetic steel sheeting is a valuable resource in the construction industry, where it is used for building infrastructure and temporary structures. Its strength and durability make it suitable for applications such as steel framing, reinforcement, and roofing.

In addition to its structural uses, magnetic steel sheeting is also employed in creating temporary structures, such as scaffolding and formwork. The material’s magnetic properties can be leveraged in certain construction applications, such as holding and aligning components during assembly. This enhances the efficiency and precision of construction processes.

7. Packaging and Storage Solutions

Magnetic steel sheeting is used in the creation of innovative packaging and storage solutions. In warehouses and storage facilities, magnetic storage systems are employed to maximize space utilization and improve organization. These systems use magnetic steel sheeting to create modular and adjustable shelving units that can be easily reconfigured.

In the packaging industry, magnetic steel sheeting is used to create secure and tamper-proof packaging. Its strength and durability ensure the protection of goods during transportation and storage. Additionally, the material’s magnetic properties can be used in packaging designs that require reclosable and reusable features.

8. Consumer Goods

The versatility of magnetic steel sheeting extends to the production of various consumer goods. It is used in the manufacturing of products such as kitchen utensils, office supplies, and home decor items. The material’s strength and magnetic properties enhance the functionality and design of these products.

For example, magnetic steel sheeting is used in the production of magnetic knife holders, which provide a convenient and secure way to store kitchen knives. In office supplies, magnetic steel sheeting is used to create magnetic boards and organizers. These applications demonstrate the material’s ability to combine practicality with aesthetic appeal.

9. Magnetic Separators and Filters

In industrial processes, magnetic separators and filters are essential for removing unwanted metallic impurities from materials. Magnetic steel sheeting is used in the construction of these devices, where its magnetic properties are critical for their operation.

Magnetic separators and filters are used in various industries, including mining, food processing, and recycling. The magnetic steel sheeting in these devices helps to attract and capture metallic particles, ensuring the purity and quality of the final product. This contributes to the efficiency and safety of industrial processes.

10. Robotics and Automation

The rise of robotics and automation in manufacturing has increased the demand for materials that offer precision and reliability. Magnetic steel sheeting is used in the construction of robotic systems and automated production lines. Its magnetic properties are essential for applications such as magnetic sensors, actuators, and grippers.

In automated production lines, magnetic steel sheeting is used to create components that require precise movement and control. The material’s durability and strength ensure the longevity and performance of robotic systems. This enhances the efficiency and productivity of manufacturing operations.

Advantages of Using Magnetic Steel Sheeting

The widespread use of magnetic steel sheeting in modern manufacturing is driven by several key advantages. Firstly, the material offers exceptional durability and longevity, making it a cost-effective choice for various applications. Its strength and resistance to wear and tear ensure that it can withstand the demands of industrial use.

Secondly, magnetic steel sheeting is highly versatile and adaptable. It can be easily fabricated into different shapes and sizes, allowing manufacturers to customize it for specific applications. This flexibility makes it suitable for a wide range of industries and uses.

Another significant advantage is the material’s magnetic properties, which enhance the performance and efficiency of many applications. Whether it’s in electric motors, medical devices, or industrial filters, the ability to conduct and manipulate magnetic fields is a valuable feature.

Challenges and Considerations

Despite its many advantages, there are some challenges and considerations associated with the use of magnetic steel sheeting. One potential drawback is the material’s weight, which can be a concern in applications where weight reduction is critical. Additionally, magnetic steel sheeting may require special handling and fabrication techniques to ensure optimal performance.

Another consideration is the cost of magnetic steel sheeting, which can be higher than that of non-magnetic materials. Manufacturers need to weigh the benefits of its magnetic properties against the additional costs. However, in many cases, the long-term advantages and improved performance justify the investment.

Future Trends and Innovations

The future of magnetic steel sheeting in manufacturing looks promising, with ongoing research and development focused on enhancing its properties and expanding its applications. Emerging technologies, such as advanced manufacturing techniques and new alloy compositions, are expected to further improve the performance of magnetic steel sheeting.

Future trends may include the development of lighter and stronger magnetic steels, as well as innovations that enhance their magnetic properties. Additionally, new applications in fields such as renewable energy, healthcare, and advanced robotics are likely to drive demand for magnetic steel sheeting.

Case Studies and Real-World Examples

To illustrate the impact of magnetic steel sheeting, let’s look at some real-world examples and case studies. One notable example is the use of magnetic steel sheeting in the production of electric vehicles (EVs). Leading automakers have integrated magnetic steel sheeting into their EV motors, resulting in higher efficiency and longer driving ranges.

Another case study involves the use of magnetic steel sheeting in wind turbine generators. A leading renewable energy

company reported significant improvements in energy output and reliability after switching to magnetic steel sheeting for their generator components.

In the medical field, a major hospital implemented magnetic steel sheeting in their MRI machines, enhancing the imaging quality and reducing maintenance costs. These examples highlight the tangible benefits and wide-ranging applications of magnetic steel sheeting in modern manufacturing.

Conclusion

Magnetic steel sheeting has proven to be a game-changer in modern manufacturing, offering a unique combination of strength, durability, and magnetic properties. From automotive and electronics to renewable energy and medical equipment, its applications are vast and varied. The material’s advantages, including its versatility and efficiency, make it an invaluable resource for manufacturers across different industries.

As technology continues to advance, the future holds even greater potential for magnetic steel sheeting. Innovations and new applications will further solidify its role as a cornerstone of modern manufacturing, driving progress and enabling new possibilities. Whether you’re in the automotive sector, renewable energy, or any other industry, magnetic steel sheeting is a material worth considering for its exceptional properties and wide-ranging benefits.