Introduction to Laminated Magnets

Laminated magnets are specialized magnetic materials made by stacking thin layers, or laminations, of ferromagnetic materials, which are often coated to insulate them from each other. This construction technique is a critical innovation that enhances the performance of magnets in numerous applications. Laminated magnets are essential in many devices, ranging from electric motors to transformers, due to their efficiency, durability, and versatility.

The fundamental principle behind laminated magnets is to minimize energy losses caused by eddy currents. Eddy currents are loops of electrical current that are induced within conductors by a changing magnetic field in the conductor. These currents can produce heat and lead to wasted energy. By laminating the magnetic material, the thickness of each layer is kept minimal, thereby reducing the area available for the eddy currents to form. This structure ensures that laminated magnets operate with greater efficiency compared to solid magnets.

The Importance of Laminated Magnets in Modern Technology

In our increasingly technology-driven world, the demand for efficient and reliable components is paramount. Laminated magnets play a significant role in numerous applications across various industries, supporting the operation of electric and electronic devices. Their unique properties not only enhance performance but also contribute to energy savings, which is critical in today’s eco-conscious society.

The Construction of Laminated Magnets

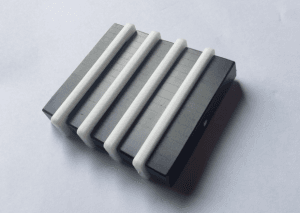

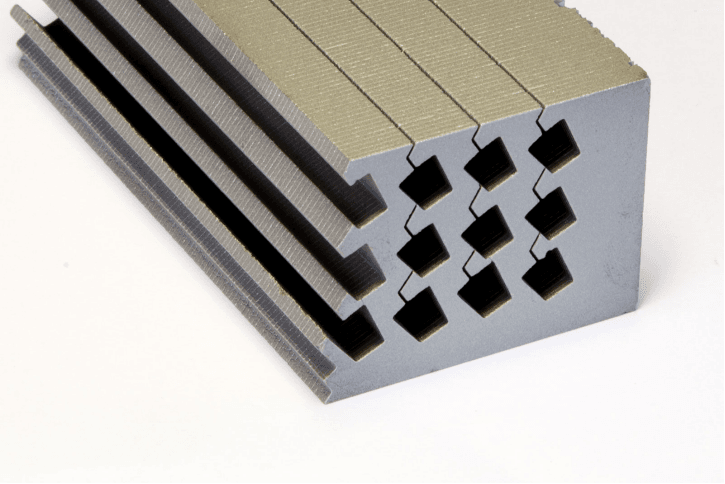

Laminated magnets are made by stacking thin sheets of magnetic material, usually silicon steel, which is renowned for its excellent magnetic properties. These laminations are coated with an insulating layer, typically made from resin or varnish, to prevent electrical conduction between the layers. The thickness of each lamination can vary depending on the specific application, but it is generally kept below a few millimeters.

The laminations are bonded together through various methods, including adhesive bonding or pressing, to form a solid structure. This layered approach is crucial for optimizing the magnetic performance while reducing energy losses, making laminated magnets ideal for high-efficiency applications.

Advantages of Laminated Magnets

1. Reduced Eddy Current Losses

The most prominent advantage of laminated magnets is their ability to significantly reduce eddy current losses. In solid magnetic materials, eddy currents can lead to substantial energy waste, resulting in reduced efficiency. The layered structure of laminated magnets minimizes the pathways available for these currents, thereby allowing the magnets to operate at higher efficiency levels. This characteristic is particularly valuable in applications like electric motors, where energy conservation is crucial.

2. Enhanced Magnetic Performance

Laminated magnets provide superior magnetic performance due to their design. The thin layers enable better control over the magnetic field generated by the magnet, resulting in more precise and effective performance. This enhanced magnetic capability is essential in applications that require high levels of accuracy, such as in sensors and actuators.

3. Improved Thermal Stability

Thermal stability is another significant advantage of laminated magnets. The insulation between the layers helps to dissipate heat more effectively, allowing the magnets to withstand higher temperatures without losing their magnetic properties. This characteristic is especially critical in high-temperature environments, such as automotive applications where components may experience significant thermal fluctuations.

4. Weight Reduction

Laminated magnets are generally lighter than solid magnets, which can be a considerable advantage in applications where weight is a critical factor. This weight reduction can contribute to overall system efficiency, particularly in transportation industries, including automotive and aerospace, where reducing weight can lead to improved fuel efficiency and performance.

5. Cost-Effectiveness

Despite the advanced technology involved in producing laminated magnets, they can be a cost-effective solution for many applications. The production process allows for the optimization of material usage, reducing waste and lowering costs. Additionally, the improved performance of laminated magnets can lead to savings over time in energy consumption and maintenance, making them an attractive choice for manufacturers.

Applications of Laminated Magnets

Laminated magnets are utilized in a wide variety of applications across numerous industries. Here are some of the primary sectors where laminated magnets play a critical role:

1. Electric Motors

Electric motors are one of the most common applications for laminated magnets. The reduced eddy current losses and enhanced magnetic performance of laminated designs contribute significantly to the efficiency of electric motors. These motors are used in countless applications, from household appliances to industrial machinery and electric vehicles. In electric vehicles, for instance, high-performance laminated magnets are crucial for optimizing energy use and extending battery life.

2. Generators

Laminated magnets are essential components in electrical generators, converting mechanical energy into electrical energy. Their ability to maintain performance under a variety of conditions and temperatures makes them suitable for use in renewable energy systems, such as wind turbines and hydroelectric plants. The efficiency gains achieved through the use of laminated magnets can lead to increased energy output and reduced operational costs.

3. Transformers

Transformers, which are vital for transferring electrical energy between circuits, also benefit from the use of laminated magnets. The laminated construction minimizes energy losses during the conversion process, leading to more efficient operation. This efficiency is particularly important in power distribution systems, where minimizing losses can significantly reduce operational costs and enhance the overall reliability of the grid.

4. Magnetic Sensors

In the realm of automation and control, laminated magnets are used in magnetic sensors, which play a crucial role in applications such as automotive systems, consumer electronics, and industrial automation. The enhanced magnetic performance provided by laminated magnets allows for precise measurements and reliable operation of these sensors, contributing to improved functionality in various systems.

5. Magnetic Resonance Imaging (MRI)

The medical field also relies on laminated magnets, particularly in Magnetic Resonance Imaging (MRI) machines. The high magnetic performance and thermal stability of laminated magnets make them ideal for generating the strong magnetic fields necessary for MRI scans. Their use in medical imaging technology enables healthcare professionals to obtain detailed images of the human body, aiding in diagnosis and treatment planning.

Future Trends in Laminated Magnets

As technology evolves, the landscape of laminated magnets continues to change, influenced by advancements in materials, manufacturing processes, and applications. Here are some trends expected to shape the future of laminated magnets:

1. Advancements in Materials

Research into new materials for laminated magnets is ongoing, with the goal of developing high-performance composites and advanced coatings. Innovations in materials science may lead to laminated magnets with even better magnetic properties, reduced weight, and enhanced thermal stability. This progress could open new possibilities for laminated magnets in high-demand applications, such as electric aircraft and energy storage systems.

2. Eco-Friendly Manufacturing Processes

With growing concerns about sustainability, there is an increasing focus on developing eco-friendly manufacturing processes for laminated magnets. Researchers are exploring greener production methods that minimize waste and reduce the environmental impact of magnet manufacturing. These advancements align with global efforts to create more sustainable industries, ultimately benefiting both manufacturers and consumers.

3. Integration with Smart Technologies

The integration of laminated magnets with smart technologies is another exciting trend. As the Internet of Things (IoT) continues to expand, the use of laminated magnets in smart devices could provide enhanced capabilities. For instance, smart sensors could utilize laminated magnets to offer real-time data on system performance and efficiency, enabling predictive maintenance and improved management of resources.

4. Expanding Applications in Renewable Energy

The shift towards renewable energy sources is likely to increase the demand for laminated magnets in wind turbines, solar energy systems, and energy storage solutions. Their efficiency and performance characteristics make them ideal for harnessing energy in these applications. As the world moves toward more sustainable energy practices, the role of laminated magnets will become increasingly important.

Challenges Facing Laminated Magnets

Despite the many advantages of laminated magnets, there are challenges that manufacturers and researchers must address to optimize their use:

1. Manufacturing Complexity

The production of laminated magnets can be complex, requiring precise alignment and bonding of layers to ensure optimal performance. Any misalignment or inconsistencies in the layers can negatively impact the magnetic properties. Manufacturers must invest in advanced technologies and quality control measures to mitigate these challenges.

2. Material Costs

While laminated magnets can be cost-effective in the long run, the initial material costs can be higher than traditional solid magnets. This factor can be a barrier for some manufacturers, particularly smaller companies with limited budgets. Research into alternative materials and manufacturing techniques could help reduce these costs in the future.

3. Competition from Alternative Technologies

The magnetic materials market is competitive, with ongoing advancements in alternative technologies, such as rare-earth magnets and soft magnetic composites. These materials can offer different advantages, leading to potential competition for laminated magnets in certain applications. To maintain their market position, laminated magnets must continue to evolve and demonstrate their unique benefits.

Conclusion

Laminated magnets represent a remarkable advancement in magnetic technology, offering a range of benefits that make them indispensable in various applications. Their ability to reduce eddy current losses, enhance magnetic performance, improve thermal stability, and provide cost-effective solutions positions them as a vital component in modern technology.

As industries continue to evolve, the demand for efficient and reliable magnetic solutions will likely increase. Laminated magnets, with their unique properties and advantages, are poised to play a crucial role in the development of innovative products and systems across multiple sectors.

The future of laminated magnets looks promising, with ongoing research and development leading to advancements in materials, manufacturing processes, and applications. By understanding the advantages and challenges associated with laminated magnets, industries can leverage their potential to improve efficiency and performance in a wide array of applications.

In summary, laminated magnets are not only pivotal in current technologies but also hold significant promise for future advancements. As we continue to explore the potential of these remarkable materials, it becomes clear that laminated magnets will shape the future of various fields and industries, ultimately contributing to a more efficient and sustainable technological landscape.

Potential Innovations and Research Directions

1. Advanced Coatings and Insulation

Future innovations may focus on developing advanced coatings and insulation materials that enhance the performance of laminated magnets further. These innovations could include using nanomaterials or smart polymers that respond to environmental changes, providing added functionality and efficiency.

2. Enhanced Performance Under Extreme Conditions

Research may also aim to improve the performance of laminated magnets under extreme conditions, such as high temperatures, corrosive environments, or high-frequency applications. By enhancing their resilience, laminated magnets could find applications in sectors like aerospace, military, and specialized industrial processes.

3. Increased Focus on Sustainability

As sustainability becomes a key concern for industries, the development of environmentally friendly laminated magnets may gain traction. Researchers may explore biodegradable or recyclable materials, ensuring that the entire lifecycle of laminated magnets aligns with global sustainability goals.

4. Automation and Smart Manufacturing

The integration of automation and smart manufacturing techniques into the production of laminated magnets could lead to increased efficiency and reduced costs. Advanced manufacturing processes, such as 3D printing, may also enable the production of complex geometries and customized designs tailored to specific applications.

Conclusion

In conclusion, laminated magnets stand at the forefront of magnetic technology, combining advanced design with significant benefits. Their ability to reduce energy losses, enhance performance, and provide cost-effective solutions makes them indispensable across various applications. As the world moves towards increased energy efficiency and sustainability, laminated magnets will continue to play a critical role in shaping the future of technology. With ongoing research and innovation, the possibilities for laminated magnets are vast, promising a bright future for this essential component in the technological landscape.