Introduction

Consider a manufacturing facility that has been plagued by impurities in their raw materials, resulting in consistent quality issues with their finished products. After years of struggling with this problem, the implementation of a magnetic separator completely transformed their operations. This piece of equipment, which is not widely known or understood, is critical in many industries for its ability to improve product purity and efficiency. So, what exactly is a magnetic separator used for? Let’s take a closer look at its applications and examine some real-life examples.

What is a Magnetic Separator?

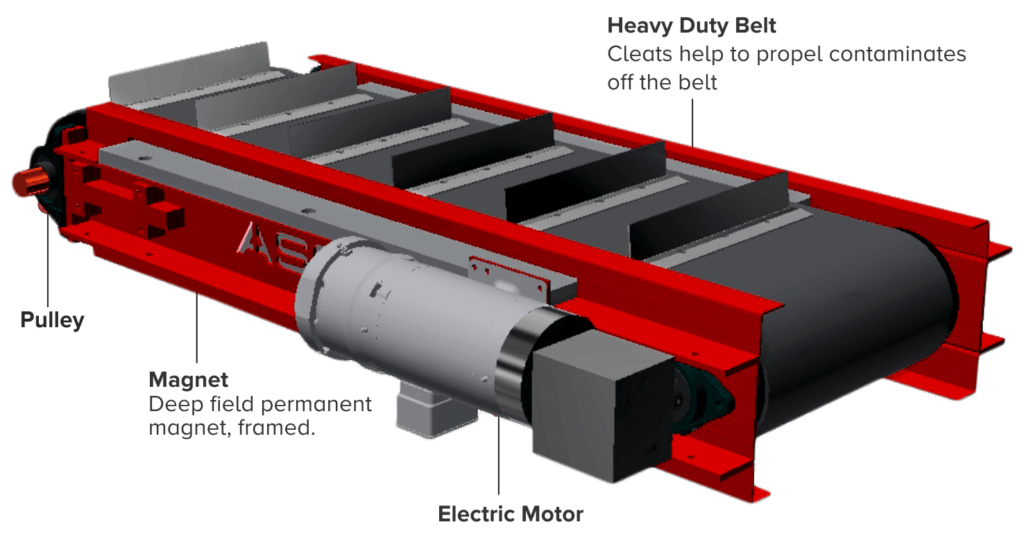

A magnetic separator basically is an iron-removal. It is a device that utilizes a magnetic force to eliminate magnetic substances from soil, dust, and other small particles in industrial settings. Generally, this machine consists of a conveyor belt that moves material through a magnetic field; magnetic particles are drawn to the magnet and separated from non-magnetic particles. This uncomplicated yet efficient process is crucial in various industries, including mining, recycling, and more.

Industrial Applications of Magnetic Separators

Mining Sector

In mining, magnetic separators play a crucial role in extracting metallic ores from surrounding material. For example, in iron ore purification, magnetic separators are used to remove impurities, leaving a higher quality, purer metal to go forward into production.

Recycling Industry

The recycling sector greatly benefits from magnetic separation technology. Here, separators are used to sort metallic waste from non-metallic waste, enabling efficient recycling and reprocessing of materials like copper, aluminum, and steel.

Food and Pharmaceutical Industries

Magnetic separators ensure product safety in food and pharmaceutical production by removing tiny metallic particles that could be a health hazard. This process helps in maintaining stringent quality controls essential for industry compliance and consumer safety.

Chemical Industry

In the chemical industry, these separators are used to purify chemicals by removing metal impurities which can alter chemical compositions and potentially ruin product batches.

Technological Innovations in Magnetic Separation

Advancements and Case Studies

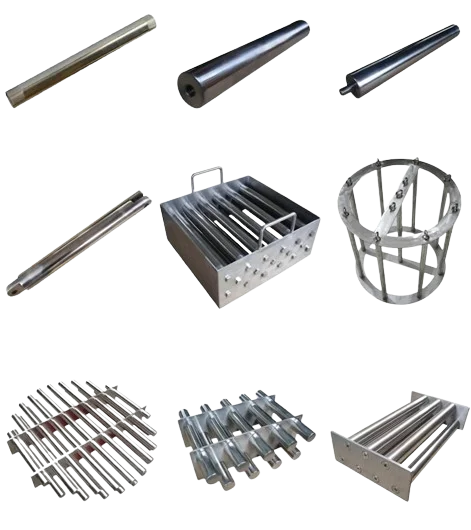

Recent technological advancements have seen the development of high-gradient magnetic separators that offer greater effectiveness in separating fine magnetic particles. For instance, the introduction of rare earth magnets in separators has allowed for more precise separations, increasing the yield and purity of the separated materials.

Automation in Magnetic Separation

Automation and AI have been integrated into magnetic separation processes to enhance efficiency and reduce human error. Automated systems can adjust the magnetic intensity needed for different materials, improving the quality of separation.

Case Study: Choosing the Right Magnetic Separator

Factors to Consider

When selecting a magnetic separator, one must consider the type of material, the volume of material, and the desired level of purity. The case of a metal fabrication company illustrates this well; by choosing a custom-designed magnetic separator, they were able to triple their output while maintaining product quality.

Market Outlook and Challenges

Global Trends

The global market for magnetic separators is expected to grow, driven by rising demand in industries such as mining and recycling. Asia-Pacific is projected to be a significant market due to large-scale industrialization in countries like China and India.

Challenges and Strategies

One of the main challenges in the magnetic separator market is the high initial investment required for advanced machinery. However, businesses can overcome this by opting for leasing models or investing in modular equipment that can be upgraded over time.

Conclusion

Magnetic separators play a crucial role in today’s industrial landscape, improving product quality and operational efficiency across multiple industries. As technology continues to advance, their importance will only grow, offering a future where purity and efficiency are attainable at every stage of production. If you want to enhance your material processing lines, investing in the right magnetic separator could be the solution to achieving higher productivity and better product quality. Assess your requirements, weigh the potential return on investment, and take the leap towards more efficient production now.