Introduction

In the realm of precision engineering, the quest for more accurate, responsive, and efficient motion control systems is ever-present. From medical devices that require meticulous accuracy to consumer electronics that demand seamless user experience, the underlying technology driving these advancements often goes unnoticed. Among these innovations, Voice Coil Motors (VCMs) stand out for their unique combination of simplicity and precision. But what exactly makes VCMs so special, and how do they compare to traditional motors? This article delves into the versatility and precision of Voice Coil Motors, exploring their fundamental principles, various applications, and the crucial role of custom magnets in their design.

What is a Voice Coil Motor?

Voice Coil Motors are a type of direct-drive motor that utilize electromagnetic forces to produce linear or rotary motion. Unlike conventional motors, which rely on rotating magnetic fields, VCMs generate motion through the interaction of a magnetic field and a coil of wire. This mechanism is fundamentally rooted in the Lorentz Force Law, which describes the force experienced by a charged particle moving through a magnetic field. Historically, VCMs were first developed for use in audio equipment, such as loudspeakers, where precise control over diaphragm movement was essential for sound reproduction.

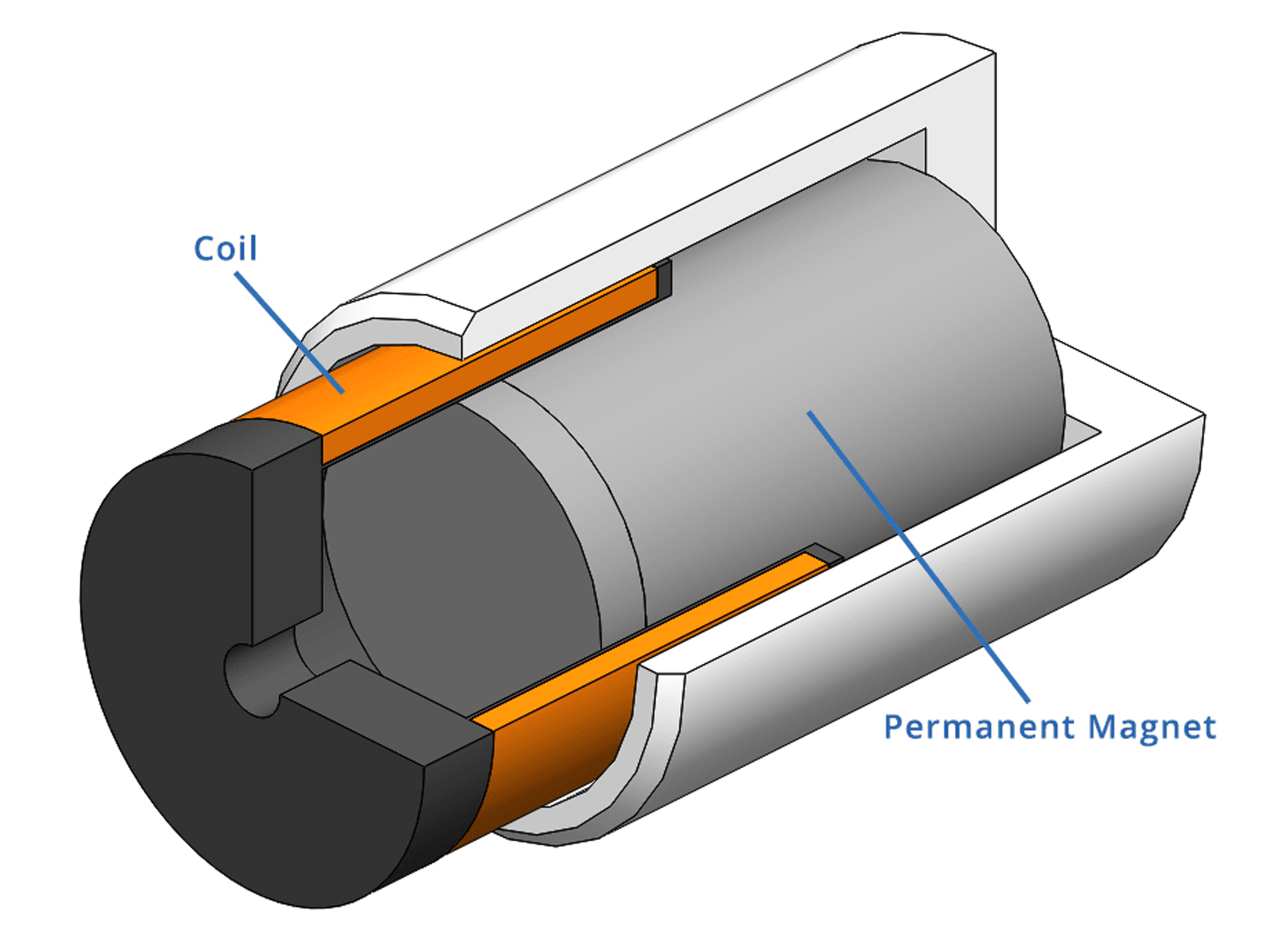

A VCM typically comprises three main components: a stationary magnetic housing, a moving coil (or voice coil), and a suspension system. The coil is suspended within the magnetic field, and when an electrical current passes through the coil, it generates a force that moves the coil. The direction and magnitude of this force are directly proportional to the current and the magnetic field strength, allowing for precise control over the movement.

How Voice Coil Motors Work

The operation of a VCM is based on electromagnetic principles. When an electric current flows through the coil, it interacts with the magnetic field generated by the permanent magnets, producing a force. This force causes the coil to move linearly or rotate, depending on the design of the VCM. The motion generated can be extremely precise, with high-resolution feedback mechanisms in place to ensure accurate positioning.

VCMs are known for their ability to produce both linear and rotary motion. Linear VCMs are often used in applications requiring precise linear displacement, such as in autofocus mechanisms in cameras or precision stages in scientific instruments. Rotary VCMs, on the other hand, are used in applications like hard disk drives, where precise angular positioning is critical.

The control systems used in VCMs are crucial for their precision. These systems typically include feedback loops that monitor the position and adjust the current to maintain the desired movement. This real-time adjustment capability allows VCMs to respond rapidly to changes, making them ideal for applications where speed and accuracy are paramount.

Differences Between Voice Coil Motors and Traditional Motors

VCMs differ from traditional motors in several key aspects, particularly in design and functionality. Traditional motors, such as stepper motors or DC motors, typically use a rotating magnetic field to induce movement in the rotor. This often involves complex gearing systems and results in a more mechanical and less precise operation compared to VCMs.

One of the primary advantages of VCMs is their simplicity and precision. Since they rely on a direct electromagnetic force, they can achieve very smooth and accurate motion without the mechanical limitations of traditional motors. This makes VCMs particularly useful in applications where fine control is necessary, such as in optical systems or medical devices.

However, VCMs do have some limitations. They generally require more precise control electronics and can have higher power requirements depending on the application. Additionally, their open-loop nature means that without proper feedback systems, their accuracy can be compromised. Despite these considerations, the benefits of VCMs, particularly in terms of response time and smooth operation, often outweigh these limitations.

Applications of Voice Coil Motors

Voice Coil Motors are used in a wide range of applications due to their precision and responsiveness. In the medical field, VCMs are integral to the operation of MRI machines, where they are used to precisely position imaging coils. They are also used in surgical robots, where their ability to provide fine, controlled movements is critical.

In industrial automation, VCMs are used in robotics and automated machinery, providing precise control over the positioning and movement of components. This is especially important in manufacturing processes that require high precision, such as semiconductor fabrication or assembly of delicate electronic components.

Consumer electronics also benefit from VCM technology. For instance, VCMs are used in the autofocus systems of cameras, where they enable rapid and accurate focusing. In hard disk drives, VCMs are responsible for moving the read/write head, allowing for precise data access.

The aerospace and defense industries also utilize VCMs, particularly in applications such as targeting systems and stabilization mechanisms. The high precision and reliability of VCMs make them suitable for these demanding applications.

The Role of Custom Neodymium Magnets in VCMs

Custom Neodymium Magnets play a crucial role in the performance of Voice Coil Motors. These magnets are known for their strong magnetic fields, which are essential for generating the necessary forces in VCMs. The customization of these magnets allows for optimization of the magnetic field, which can significantly enhance the performance of the motor.

For example, in applications where space is limited, custom neodymium magnets can be designed to provide the necessary magnetic field strength within a smaller footprint. This is particularly important in consumer electronics, where miniaturization is a key consideration. Additionally, custom magnets can be tailored to specific applications, ensuring that the VCM operates efficiently under various conditions.

At MagnetsTek, we offer a range of Custom Neodymium Magnets designed to meet the specific needs of our clients. Whether for medical devices, industrial automation, or consumer electronics, our custom magnets are engineered to enhance the performance of Voice Coil Motors in a wide range of applications.

Innovations and Future Trends in Voice Coil Motors

The field of Voice Coil Motors is continually evolving, with ongoing innovations aimed at improving performance and expanding their range of applications. Advances in materials science, for example, are leading to the development of new magnet and coil materials that offer better performance characteristics. This includes materials that can operate at higher temperatures or provide stronger magnetic fields.

Another trend is the miniaturization of VCMs, driven by the demand for smaller and more efficient components in electronics and medical devices. This trend is particularly evident in the consumer electronics industry, where the size of devices such as smartphones and cameras continues to decrease while their functionality increases.

The integration of VCMs with smart technologies is also a growing trend. This includes the use of artificial intelligence (AI) and the Internet of Things (IoT) to enhance control and monitoring of VCM systems. These technologies can improve the precision and efficiency of VCMs, making them even more versatile and capable of handling complex tasks.

Choosing the Right Voice Coil Motor for Your Application

Selecting the appropriate Voice Coil Motor for a specific application involves several key considerations. First, it is important to understand the load requirements, including the force or torque needed, as well as the precision required. This will help determine the size and type of VCM needed, as well as the specifications for the coil and magnets.

Environmental factors, such as temperature and humidity, should also be considered, as they can affect the performance of the VCM. In applications where the motor will be exposed to harsh conditions, it may be necessary to use materials that are resistant to corrosion or high temperatures.

Customization options are another important factor to consider. Many applications require VCMs to be tailored to specific needs, such as unique mounting configurations or specialized feedback systems. At MagnetsTek, we offer a range of customization options, including custom coil designs and Custom Neodymium Magnets, to ensure that our VCMs meet the exact requirements of our clients.

Finally, choosing a reliable supplier is crucial. It is important to work with a supplier who has a proven track record in producing high-quality VCMs and who can provide the necessary support and expertise. This includes offering technical assistance during the selection process and providing ongoing support after purchase.

Conclusion

Voice Coil Motors are a versatile and precise solution for a wide range of applications, from medical devices and industrial automation to consumer electronics and aerospace. Their unique combination of simplicity and precision makes them ideal for tasks that require fine control and responsiveness. As technology continues to advance, the role of VCMs in various industries is likely to grow, driven by innovations in materials, miniaturization, and smart technologies.

For those looking to explore the potential of Voice Coil Motors in their applications, it is important to consider factors such as load requirements, environmental conditions, and customization options. Working with a reliable supplier, such as MagnetsTek, can ensure that you receive high-quality VCMs that meet your specific needs. With our expertise in custom magnet solutions, including Custom Neodymium Magnets, we are well-positioned to support your VCM requirements and help you achieve the precision and performance you need.