Wet pressed ferrite magnets are a vital component in various industries, offering a blend of durability, versatility, and affordability. As a subset of ferrite magnets, they are particularly valued for their exceptional magnetic properties and wide-ranging applications, from motors to industrial equipment. Understanding their composition, manufacturing processes, types, and applications provides deeper insight into why they are a preferred choice in many sectors.

The Basics of Ferrite Magnets

Ferrite magnets, also known as ceramic magnets, are composed primarily of iron oxide combined with one or more metallic elements. They are classified as hard magnets, which means they retain their magnetism over time and are widely used in permanent magnet applications. Due to their resistance to corrosion, low cost, and high magnetic strength, ferrite magnets are ideal for both industrial and consumer applications.

What Makes Wet Pressed Ferrite Magnets Unique?

Wet pressed ferrite magnets are manufactured using a wet pressing method, which differs from the dry pressing technique commonly used for other types of ferrite magnets. In this process, raw materials such as strontium carbonate and iron oxide are mixed with water to form a slurry. This mixture is then compacted into molds under high pressure, creating precise shapes and sizes. The wet pressing process allows for the production of anisotropic ferrite magnets, which have a preferred direction of magnetization. This anisotropy enhances the magnetic performance, making wet pressed ferrite magnets especially suitable for applications requiring high energy output and stable magnetic fields.

The Role of Strontium in Wet Pressed Ferrite Magnets

Strontium ferrite magnets, also referred to as Sr ferrite magnets, are the most common type of wet pressed ferrite magnets. Strontium is a key element in their composition, contributing to improved magnetic properties compared to barium ferrite magnets. Strontium ferrite magnets exhibit superior coercivity and remanence, which means they can maintain a strong magnetic field even under challenging conditions. These characteristics make them indispensable in demanding applications like automotive motors and industrial equipment.

Varieties of Wet Pressed Ferrite Magnets

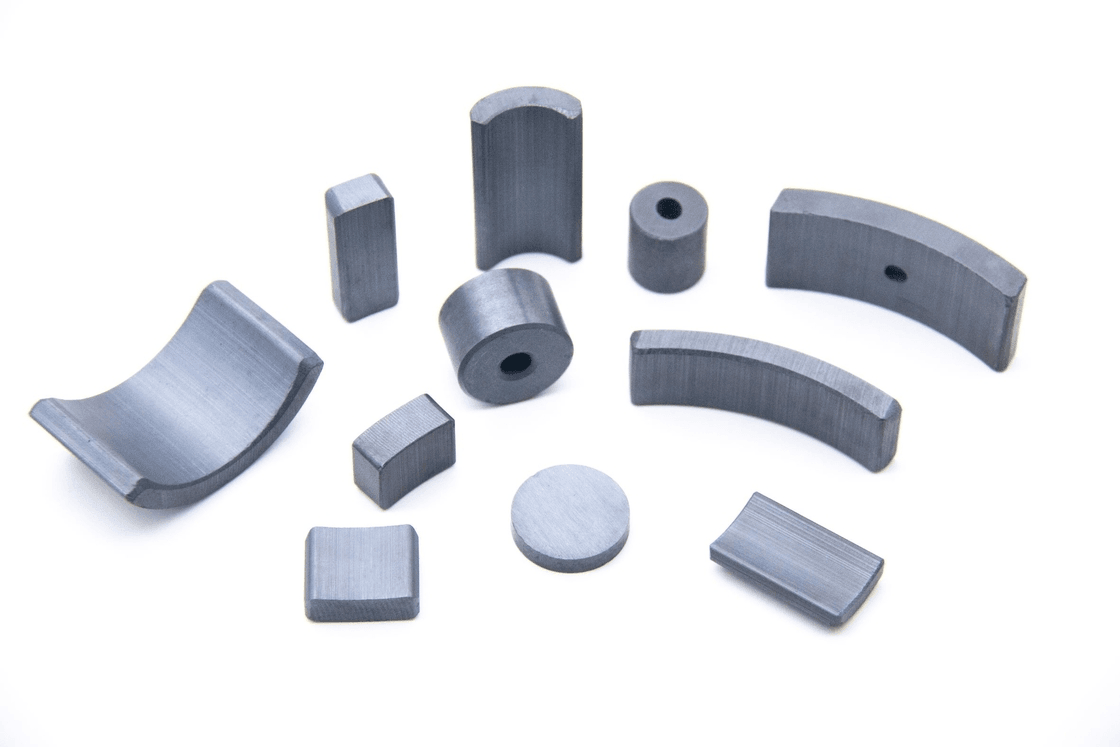

Wet pressed ferrite magnets come in various shapes and configurations to meet the needs of different industries. Among the most popular are arc ferrite magnets, which are often used in electric motors and generators. Arc-shaped ferrite magnets, also known as ferrite magnet arcs or ceramic magnet arcs, are designed to fit around curved surfaces, making them ideal for rotor and stator assemblies. Their ability to provide consistent and strong magnetic fields contributes to the efficiency of motor systems.

Another notable type is anisotropic ferrite magnets, which are specifically engineered to have a single direction of magnetization. This property is achieved during the wet pressing process by applying a magnetic field to align the particles in a specific orientation. Anisotropic ferrite magnets are widely used in applications requiring precise magnetic performance, such as in medical devices and high-efficiency motors.

Applications of Wet Pressed Ferrite Magnets

Wet pressed ferrite magnets are highly regarded for their efficiency and versatility, particularly in motors and industrial applications. Their unique properties make them the preferred choice for key industries, ensuring long-lasting and cost-effective performance. This section emphasizes the significant roles of ferrite magnets for motors and ferrite magnets for industrial applications, while also exploring their contributions to other fields.

Ferrite Magnets for Motors

Ferrite magnets play a pivotal role in motor systems, making them a cornerstone in both the automotive and industrial sectors. Their high durability, cost-efficiency, and stable performance in demanding environments have made them indispensable in a variety of motor applications.

- Electric Vehicle Motors: Ferrite magnets are widely used in motors that power electric and hybrid vehicles. Their ability to generate strong and consistent magnetic fields ensures optimal torque and efficiency, even under high operating temperatures. For instance, wet pressed ferrite magnets are a cost-effective alternative to rare earth magnets, maintaining performance while lowering production costs for automakers.

- AC and DC Motors: In both alternating current (AC) and direct current (DC) motors, ferrite magnets provide the magnetic fields necessary for energy conversion. These magnets help improve motor efficiency and reliability, making them suitable for a range of uses, from household appliances to industrial equipment.

- Stepper Motors: Stepper motors, often used in robotics and automation systems, rely on ferrite magnets for precise movement control. The anisotropic properties of wet pressed ferrite magnets enhance their magnetic alignment, allowing for smoother and more accurate operations.

Wet pressed ferrite magnets are particularly valued for their resistance to demagnetization, a crucial characteristic in motors exposed to high currents and fluctuating magnetic fields. Their widespread use in motors underscores their reliability and performance in modern engineering.

Ferrite Magnets for Industrial Applications

In industrial environments, ferrite magnets are fundamental to the operation of machinery and systems that require durable and efficient components. Their ability to withstand harsh conditions, including extreme temperatures and exposure to chemicals, makes them a reliable choice for demanding industrial applications.

- Pumps and Compressors: Ferrite magnets are integral to the motors used in pumps and compressors across industries like water treatment, food processing, and chemical manufacturing. Their robust performance ensures consistent flow rates and pressure regulation, even in environments with high levels of wear and tear.

- Conveyor Systems: Wet pressed ferrite magnets are used in motorized conveyor belts, which transport materials in factories, warehouses, and mining facilities. Their magnetic strength and resistance to environmental factors contribute to the longevity and efficiency of these systems.

- Industrial Automation: In automated machinery and robotics, ferrite magnets are employed in motors that enable precise movement and positioning. Their anisotropic properties ensure stable magnetic fields, which are essential for accuracy and repeatability in industrial tasks.

The cost-effectiveness of ferrite magnets, combined with their ability to maintain performance in challenging environments, makes them a vital component in industrial machinery.

Supporting Roles of Wet Pressed Ferrite Magnets

While ferrite magnets for motors and industrial applications dominate the spotlight, wet pressed ferrite magnets also excel in other sectors:

- Consumer Electronics: Ferrite magnets are used in speakers, microphones, and small electric motors for devices like fans and kitchen appliances. Their low cost and reliable performance make them ideal for mass-market consumer goods.

- Renewable Energy: In wind turbines, ferrite magnets are utilized in generators to convert mechanical energy into electricity. Similarly, in solar trackers, they drive motors that adjust panel angles to optimize sunlight capture.

- Medical Equipment: Ferrite magnets find applications in medical devices such as imaging systems and magnetic drug delivery tools. Their precision and reliability make them suitable for critical healthcare technologies.

- Automotive Sensors and Actuators: Beyond electric motors, ferrite magnets are employed in automotive sensors to detect speed and position, as well as in actuators for controlling mechanisms like throttle systems and automated windows.

Why Ferrite Magnets Excel in Motors and Industry

The prominence of ferrite magnets in motors and industrial applications stems from their unique combination of properties:

- High Durability: Wet pressed ferrite magnets resist physical and chemical wear, ensuring long-term functionality in motors and heavy-duty machinery.

- Stable Magnetic Fields: Their anisotropic nature, achieved during manufacturing, enhances the alignment of magnetic particles, ensuring consistent performance in precision applications.

- Cost Efficiency: Compared to rare earth magnets, ferrite magnets are significantly more affordable, making them a practical choice for high-volume production in motors and industrial equipment.

- Environmental Resistance: These magnets perform reliably in extreme temperatures, humidity, and corrosive environments, making them ideal for both indoor and outdoor use.

Industry-Specific Variants

Wet pressed ferrite magnets are tailored to meet the specific needs of various industries. For instance, arc ferrite magnets are commonly used in the motor industry, where their shape and magnetic strength enhance motor efficiency. Ferrite magnets for industrial applications are designed to withstand harsh environments, ensuring consistent performance in demanding conditions.

Strontium ferrite magnets are another key variant, known for their superior magnetic properties. These magnets are often used in applications requiring high energy density and stable performance over time. The versatility of Sr ferrite magnets makes them suitable for a wide range of uses, from automotive systems to industrial machinery.

Advantages of Wet Pressed Ferrite Magnets

One of the primary advantages of wet pressed ferrite magnets is their affordability. Compared to other types of permanent magnets, such as neodymium or samarium cobalt, ferrite magnets are significantly less expensive to produce. This cost-effectiveness makes them accessible for various applications without compromising on performance.

Another benefit is their resistance to corrosion and demagnetization. Wet pressed ferrite magnets can operate effectively in environments with high humidity and temperature fluctuations, making them ideal for outdoor and industrial use. Their robust nature ensures long-term reliability, even in harsh conditions.

Additionally, the wet pressing process allows for greater flexibility in designing complex shapes and sizes. This versatility is particularly advantageous in industries like automotive and electronics, where precise configurations are often required.

Challenges and Considerations

Despite their many advantages, wet pressed ferrite magnets have certain limitations. Their magnetic strength is generally lower than that of rare earth magnets, which may restrict their use in applications requiring extremely high energy densities. Additionally, their brittleness can pose challenges during machining and handling, requiring careful design and manufacturing processes to minimize the risk of breakage.

However, these challenges are often outweighed by their cost-effectiveness and durability. For many applications, the performance of wet pressed ferrite magnets is more than sufficient, making them a practical and reliable choice.

Future Trends in Wet Pressed Ferrite Magnets

As industries continue to innovate, the demand for advanced magnetic materials is expected to grow. Wet pressed ferrite magnets are likely to remain a staple in many sectors, thanks to ongoing advancements in their manufacturing processes and material properties. For instance, researchers are exploring ways to enhance their magnetic strength and temperature resistance, further expanding their range of applications.

In the automotive industry, the shift towards electric vehicles is driving increased demand for motor ferrite magnets. Their affordability and performance make them an attractive option for manufacturers looking to produce cost-effective and efficient electric motors. Similarly, the rise of industrial automation and renewable energy systems is creating new opportunities for ferrite magnets in motors and generators.

Conclusion

Wet pressed ferrite magnets are a cornerstone of modern technology, offering a unique combination of affordability, durability, and versatility. From strontium ferrite magnets and anisotropic ferrite magnets to arc ferrite magnets and ceramic magnet arcs, their diverse range of variants caters to the needs of countless applications. Whether in automotive systems, industrial machinery, or consumer electronics, these magnets continue to demonstrate their value as reliable and cost-effective solutions. With ongoing advancements in their design and manufacturing, wet pressed ferrite magnets are poised to play an even greater role in the future of technology and innovation.