Iron nitride permanent magnets represent a breakthrough in magnetic materials, promising exceptional performance and cost efficiency for various applications. These magnets, based on the FeN compound family, combine affordability with high magnetic strength, making them a compelling alternative to traditional rare-earth magnets like neodymium or samarium-cobalt.

This article explores the science behind iron nitride permanent magnets, their manufacturing process, properties, applications, and how they compare to existing magnet technologies.

The Science Behind Iron Nitride Magnets

Iron nitride (FeN) is a compound formed by introducing nitrogen into an iron matrix. This results in a crystalline structure with unique magnetic properties. Among the different iron nitride phases, Fe₁₆N₂ has garnered significant attention due to its extraordinary magnetic performance. Researchers have demonstrated that Fe₁₆N₂ exhibits a high saturation magnetization, reaching up to 2.9 Tesla, which is considerably higher than most conventional magnets.

The superior magnetic performance of Fe₁₆N₂ arises from its molecular arrangement. The inclusion of nitrogen atoms alters the electronic structure of iron, boosting its magnetic moment. This enhancement allows Fe₁₆N₂ to achieve remarkable energy product values—a key parameter indicating how much magnetic energy a material can store.

Manufacturing Iron Nitride Magnets

The production of iron nitride permanent magnets involves precise control over chemical composition and microstructure. Typically, the process begins with high-purity iron. The following steps outline the general methodology:

Nitrogenation: Iron is exposed to nitrogen-rich gases at controlled temperatures to infuse nitrogen atoms into the lattice structure. This step requires fine-tuning to achieve the desired Fe₁₆N₂ phase.

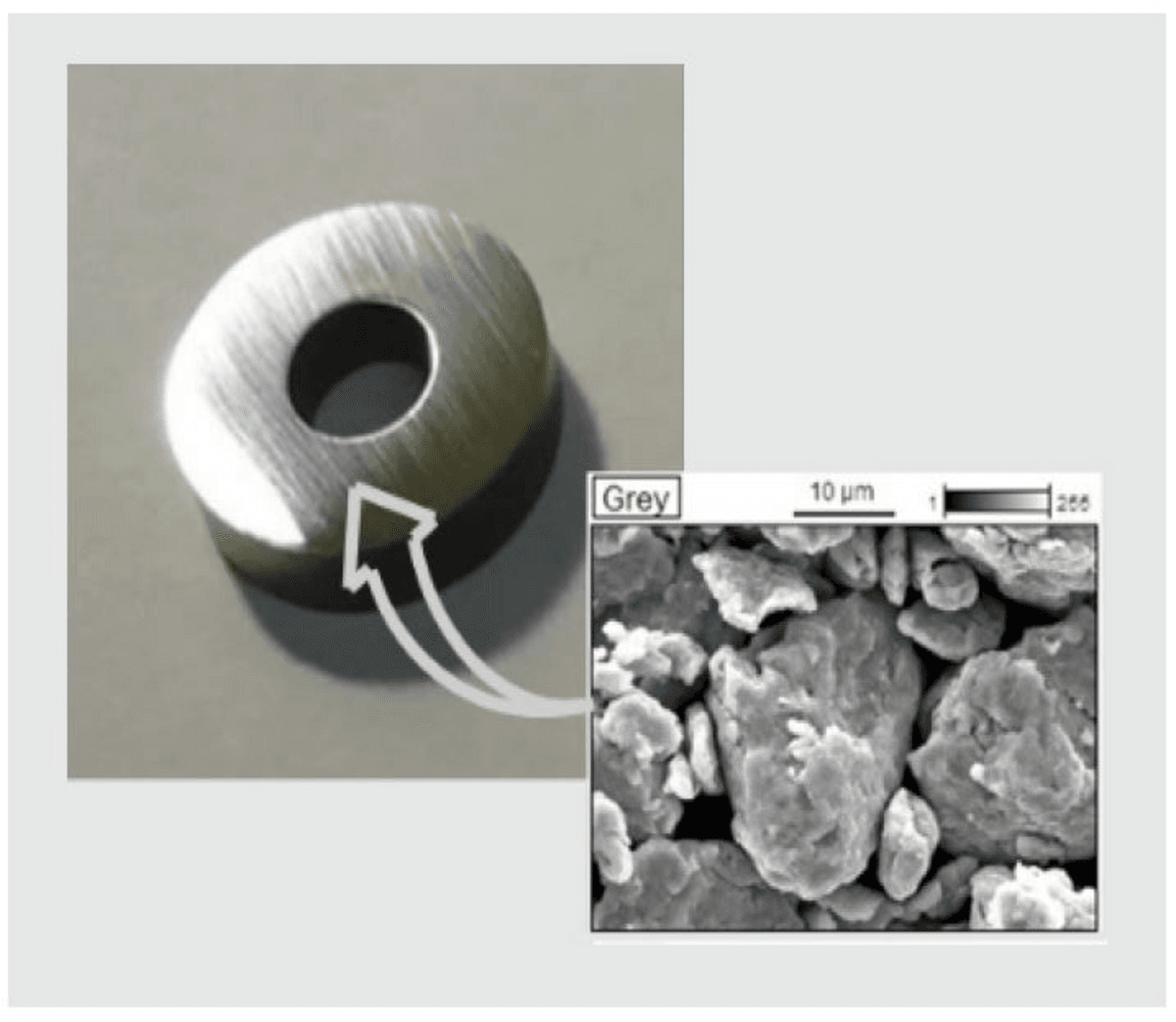

Phase Stabilization: Fe₁₆N₂ is metastable under standard conditions. Stabilizing this phase requires rapid cooling techniques or incorporating additional elements to lock the desired structure.

Compaction and Sintering: Once the Fe₁₆N₂ powder is stabilized, it can be compacted into desired shapes and sintered to form dense, solid magnets.

Coating and Finishing: To enhance durability and prevent oxidation, the magnets are typically coated with a protective layer, such as nickel or epoxy.

Despite these advancements, the production of Fe₁₆N₂ magnets faces challenges related to scalability and cost-effectiveness. Achieving consistent quality in large-scale manufacturing remains a priority for researchers.

Key Properties of Iron Nitride Magnets

Iron nitride magnets boast several properties that make them attractive for various applications. Some of the most notable features include:

High Saturation Magnetization: The Fe₁₆N₂ phase offers one of the highest saturation magnetizations among known magnetic materials.

Low Material Cost: Iron and nitrogen are abundant and inexpensive, making these magnets more cost-effective than rare-earth counterparts.

Eco-Friendliness: Unlike rare-earth magnets, iron nitride magnets do not rely on environmentally harmful mining practices.

Thermal Stability: While Fe₁₆N₂ has high magnetic performance, its thermal stability is moderate. Further advancements aim to enhance its performance at elevated temperatures.

Applications of Iron Nitride Permanent Magnets

The unique properties of iron nitride permanent magnets open up a wide range of potential applications across various industries. These include:

Automotive Sector

Iron nitride magnets are being considered for use in electric vehicles (EVs). They provide high magnetic strength while reducing reliance on rare-earth elements, which are subject to geopolitical and supply chain constraints.

Electronics and Renewable Energy

In the electronics sector, iron nitride magnets could play a crucial role in miniaturizing devices without compromising performance. Additionally, their use in wind turbines can reduce costs and environmental impact.

Magnetic Recording and Data Storage

Fe₁₆N₂ magnets are well-suited for advanced data storage technologies due to their high magnetic anisotropy, which allows for stable and compact data encoding.

Iron Nitride vs. Rare-Earth Magnets

The comparison between iron nitride and rare-earth magnets such as neodymium (NdFeB) highlights key distinctions:

- Cost Efficiency: Iron nitride magnets are significantly cheaper, thanks to the abundance of their raw materials.

- Environmental Impact: Rare-earth magnet production involves extensive mining and refining, which can harm the environment. Iron nitride magnets offer a greener alternative.

- Performance: While Fe₁₆N₂ rivals rare-earth magnets in magnetic strength, it falls short in thermal stability and long-term durability. Addressing these limitations is an active area of research.

Challenges and Future Prospects

Although iron nitride permanent magnets are promising, several hurdles need to be overcome for widespread adoption. Key challenges include:

- Phase Instability: Stabilizing the Fe₁₆N₂ phase during production is technically demanding.

- Thermal Limitations: Improving performance at high temperatures is crucial for industrial applications.

- Scalability: Scaling up production while maintaining quality and cost-effectiveness requires further technological innovation.

Research continues to focus on addressing these issues, with advancements in material science and manufacturing techniques pushing the boundaries of what iron nitride magnets can achieve.

Conclusion

Iron nitride permanent magnets represent a transformative development in magnetic materials. Combining high performance with affordability and eco-friendliness, these magnets have the potential to disrupt industries ranging from automotive to electronics. While challenges remain in their production and thermal stability, ongoing research and innovation promise to unlock their full potential, offering a sustainable alternative to rare-earth magnets.

With their advantages in cost and environmental impact, iron nitride magnets could well define the future of magnetics in a resource-conscious world.