Introduction to Magnetic Separation

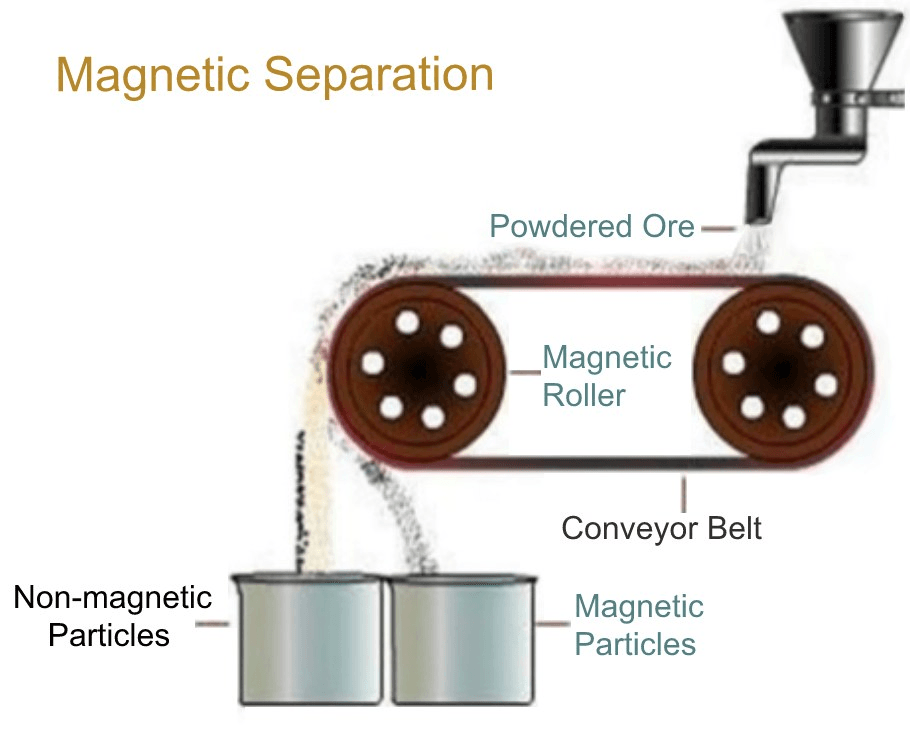

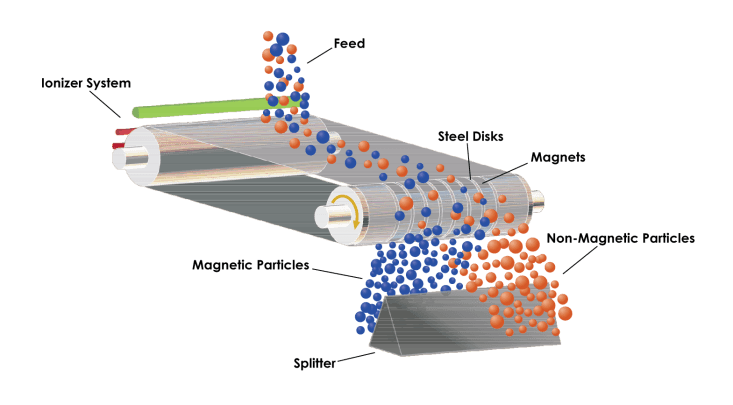

Magnetic separation is a widely-used process in various industries that leverages magnetic forces to isolate specific materials from a mixture. This technology has become an essential method for efficiently separating and purifying components, especially in sectors like mining, food production, recycling, and pharmaceuticals. The process works by applying a magnetic field to a mixture, drawing out magnetic particles while leaving non-magnetic components behind. But what makes magnetic separation a beneficial choice in various applications, and what potential drawbacks accompany its use? This article explores the advantages and disadvantages of magnetic separation and the contexts in which it’s used most effectively.

Benefits of Magnetic Separation

Introduction to Magnetic Separation

Magnetic separation is a widely-used process in various industries that leverages magnetic forces to isolate specific materials from a mixture. This technology has become an essential method for efficiently separating and purifying components, especially in sectors like mining, food production, recycling, and pharmaceuticals. The process works by applying a magnetic field to a mixture, drawing out magnetic particles while leaving non-magnetic components behind. But what makes magnetic separation a beneficial choice in various applications, and what potential drawbacks accompany its use? This article explores the advantages and disadvantages of magnetic separation and the contexts in which it’s used most effectively.

Benefits of Magnetic Separation

Magnetic separation provides several advantages, from efficiency and environmental impact to cost-effectiveness. Here are some of the main benefits:

1. Efficient and Precise Separation

One of the most significant advantages of magnetic separation is its efficiency. Magnetic separation can selectively isolate materials that are magnetically susceptible, leaving other particles behind. This ability to precisely target magnetic materials is crucial in industries such as mining and mineral processing, where the accurate separation of valuable ores from less valuable or unwanted components can have a considerable economic impact. With the right equipment, the process can handle large quantities of material while maintaining a high level of precision.

2. Cost-Effective and Energy-Efficient

Compared to other separation techniques, magnetic separation is often more cost-effective and energy-efficient. Mechanical methods like sieving or crushing can be labor-intensive and require substantial energy input, while chemical separation processes may involve expensive reagents and extensive energy usage. Magnetic separation, however, relies on magnetic fields, which typically require minimal energy and do not demand costly consumables. This results in reduced operational costs, especially for large-scale operations where energy expenses can accumulate.

3. Environmentally Friendly Process

Another advantage of magnetic separation is its low environmental impact. Traditional separation techniques, such as chemical leaching, often produce hazardous waste or involve the use of toxic chemicals that need proper disposal and management. Magnetic separation, on the other hand, is a clean process that does not generate waste byproducts. The only waste products are typically non-magnetic materials, which can be disposed of without additional environmental concerns. In industries aiming for sustainability, magnetic separation offers a greener alternative with minimal ecological footprint.

4. Improved Purity of Final Products

Magnetic separation is highly effective in achieving a high level of purity in the final product. This is particularly important in industries such as pharmaceuticals, food production, and chemicals, where purity and quality control are paramount. In food processing, for example, magnetic separators are employed to remove iron and other metals from products, thereby ensuring that consumers receive a contaminant-free product. In mining, the separation process can improve the quality of extracted ores, resulting in a more refined end product.

5. Versatility Across Industries and Applications

Magnetic separation’s versatility makes it suitable for a wide range of industries. In recycling, it can be used to separate ferrous metals from waste, ensuring that valuable materials are recycled rather than discarded. In agriculture, it can remove metallic contaminants from seeds and grains, preserving product quality. The mining industry relies on magnetic separation to extract valuable metals and minerals, while in the pharmaceutical and chemical industries, the method is used to purify products and ensure safe manufacturing standards.

6. Non-Destructive Process

Since magnetic separation relies on magnetism rather than heat or chemicals, it is a non-destructive process that preserves the physical properties of materials. This is a major benefit in applications where material integrity is crucial. For example, in recycling, magnetic separation allows for the recovery of metals without altering their structure, which enables them to be reused effectively. In contrast, some chemical processes may alter the composition of materials, limiting their potential for reuse.

7. Automation Compatibility

With advancements in automation, magnetic separation processes can be integrated into automated systems, allowing for continuous operation without extensive manual intervention. Automated magnetic separation enhances productivity and enables more consistent output, which is particularly valuable in industrial settings with high throughput demands. This integration also reduces the need for skilled labor and lowers the potential for human error, enhancing the overall reliability and efficiency of the process.

8. Safety and Reduced Health Risks

Magnetic separation is often safer than other separation techniques, as it does not require toxic chemicals or high temperatures that can pose health risks to workers. By reducing or eliminating exposure to hazardous substances, companies can create a safer working environment, comply with health and safety regulations, and reduce health-related costs. Additionally, because magnetic separation is generally a low-maintenance process, the risk of equipment-related injuries is minimized, making it an attractive option for industries with stringent safety requirements.

Applications of Magnetic Separation

Magnetic separation finds application in various industries, each benefitting from the technology in unique ways:

- Mining and Mineral Processing: To separate valuable minerals from ores, magnetic separation efficiently extracts iron and other ferromagnetic substances, improving the purity and value of the final product.

- Food and Agriculture: Magnetic separators are used to eliminate metallic contaminants in food products, ensuring consumer safety and meeting regulatory standards.

- Recycling: In recycling facilities, magnetic separation helps sort ferrous materials from non-ferrous ones, facilitating the recycling process and maximizing resource recovery.

- Pharmaceuticals and Chemicals: Magnetic separation helps purify ingredients by removing metal particles, safeguarding product quality and consumer health.

Disadvantages of Magnetic Separation

While magnetic separation offers numerous benefits, it is not without its limitations. Here are some potential disadvantages:

1. Limited to Magnetic Materials

One of the most obvious limitations is that magnetic separation can only separate materials that respond to a magnetic field. Non-magnetic materials, such as plastics, ceramics, and most types of glass, cannot be separated using this method. In processes that require the separation of multiple material types, additional separation techniques must be used alongside magnetic separation to achieve the desired results.

2. High Initial Equipment Costs

Magnetic separation systems, particularly high-strength magnetic separators, can require a substantial initial investment. Equipment costs vary depending on the strength of the magnets, the size of the unit, and its intended application. For small businesses or operations with limited budgets, the cost of purchasing and maintaining magnetic separation equipment may be a deterrent.

3. Specific Maintenance Requirements

Although magnetic separation is generally low-maintenance, certain types of magnetic separators, such as high-intensity or rare-earth magnets, require regular upkeep to maintain their effectiveness. Over time, magnetic materials can lose strength, and accumulated contaminants may reduce separation efficiency. Some separators may also require periodic cleaning and recalibration to ensure optimal performance.

4. Potential Impact on Non-Magnetic Components

In some cases, high-intensity magnetic fields can inadvertently affect non-magnetic components or interfere with nearby electronic equipment. Sensitive materials or electronics used in the vicinity of magnetic separation equipment may experience disruptions due to the magnetic field, potentially impacting equipment functionality and safety. This can be a concern in industries such as electronics or any setting with sensitive measurement devices.

5. Process Limitations

Certain applications require a high degree of separation accuracy, which magnetic separation may not always provide. For example, when working with extremely fine particles, magnetic separation may struggle to achieve the desired level of precision. This can limit its effectiveness in processes that require separation at a micro or nano-scale level, as magnetic forces may not be sufficient to separate ultra-fine particles consistently.

6. Challenges with Wet Separation

In some cases, magnetic separation is performed on wet materials, such as in mineral processing. While effective, wet magnetic separation can be challenging as it may require additional equipment to manage water flow and separation. The presence of water can complicate the separation process, potentially leading to clogging or inefficiencies. Additionally, handling wet materials can increase maintenance demands and create the need for drying processes afterward.

Overcoming the Disadvantages: Solutions and Alternatives

For industries looking to leverage magnetic separation but facing these limitations, a combination of strategies and alternative technologies can help address some of these challenges:

- Hybrid Separation Techniques: Combining magnetic separation with other techniques like gravity separation, flotation, or electrostatic separation can help achieve a more comprehensive separation process, especially in complex mixtures with both magnetic and non-magnetic particles.

- Investment in High-Efficiency Equipment: While the initial cost may be high, investing in high-quality magnetic separation equipment can provide long-term benefits, including lower maintenance costs and more consistent performance.

- Use of Advanced Magnet Materials: With the advent of neodymium magnets and other rare-earth materials, magnetic separators can achieve stronger magnetic fields, allowing for more effective separation, particularly in applications requiring fine particle separation.

Conclusion

Magnetic separation is a powerful and versatile tool used across industries for efficiently separating magnetic materials from non-magnetic ones. Its benefits include precise separation, cost-effectiveness, minimal environmental impact, and compatibility with automation, making it a valuable choice in various settings. However, magnetic separation is not without its challenges. Its effectiveness is limited to magnetic materials, and it may require significant upfront investment and specialized maintenance. For applications with demanding separation requirements or non-magnetic materials, combining magnetic separation with other methods can enhance its effectiveness and broaden its range of applications.

By understanding both the benefits and limitations of magnetic separation, industries can make informed decisions about how best to incorporate this technology into their processes, maximizing efficiency and achieving high-quality results.

Magnetic separation provides several advantages, from efficiency and environmental impact to cost-effectiveness. Here are some of the main benefits:

1. Efficient and Precise Separation

One of the most significant advantages of magnetic separation is its efficiency. Magnetic separation can selectively isolate materials that are magnetically susceptible, leaving other particles behind. This ability to precisely target magnetic materials is crucial in industries such as mining and mineral processing, where the accurate separation of valuable ores from less valuable or unwanted components can have a considerable economic impact. With the right equipment, the process can handle large quantities of material while maintaining a high level of precision.

2. Cost-Effective and Energy-Efficient

Compared to other separation techniques, magnetic separation is often more cost-effective and energy-efficient. Mechanical methods like sieving or crushing can be labor-intensive and require substantial energy input, while chemical separation processes may involve expensive reagents and extensive energy usage. Magnetic separation, however, relies on magnetic fields, which typically require minimal energy and do not demand costly consumables. This results in reduced operational costs, especially for large-scale operations where energy expenses can accumulate.

3. Environmentally Friendly Process

Another advantage of magnetic separation is its low environmental impact. Traditional separation techniques, such as chemical leaching, often produce hazardous waste or involve the use of toxic chemicals that need proper disposal and management. Magnetic separation, on the other hand, is a clean process that does not generate waste byproducts. The only waste products are typically non-magnetic materials, which can be disposed of without additional environmental concerns. In industries aiming for sustainability, magnetic separation offers a greener alternative with minimal ecological footprint.

4. Improved Purity of Final Products

Magnetic separation is highly effective in achieving a high level of purity in the final product. This is particularly important in industries such as pharmaceuticals, food production, and chemicals, where purity and quality control are paramount. In food processing, for example, magnetic separators are employed to remove iron and other metals from products, thereby ensuring that consumers receive a contaminant-free product. In mining, the separation process can improve the quality of extracted ores, resulting in a more refined end product.

5. Versatility Across Industries and Applications

Magnetic separation’s versatility makes it suitable for a wide range of industries. In recycling, it can be used to separate ferrous metals from waste, ensuring that valuable materials are recycled rather than discarded. In agriculture, it can remove metallic contaminants from seeds and grains, preserving product quality. The mining industry relies on magnetic separation to extract valuable metals and minerals, while in the pharmaceutical and chemical industries, the method is used to purify products and ensure safe manufacturing standards.

6. Non-Destructive Process

Since magnetic separation relies on magnetism rather than heat or chemicals, it is a non-destructive process that preserves the physical properties of materials. This is a major benefit in applications where material integrity is crucial. For example, in recycling, magnetic separation allows for the recovery of metals without altering their structure, which enables them to be reused effectively. In contrast, some chemical processes may alter the composition of materials, limiting their potential for reuse.

7. Automation Compatibility

With advancements in automation, magnetic separation processes can be integrated into automated systems, allowing for continuous operation without extensive manual intervention. Automated magnetic separation enhances productivity and enables more consistent output, which is particularly valuable in industrial settings with high throughput demands. This integration also reduces the need for skilled labor and lowers the potential for human error, enhancing the overall reliability and efficiency of the process.

8. Safety and Reduced Health Risks

Magnetic separation is often safer than other separation techniques, as it does not require toxic chemicals or high temperatures that can pose health risks to workers. By reducing or eliminating exposure to hazardous substances, companies can create a safer working environment, comply with health and safety regulations, and reduce health-related costs. Additionally, because magnetic separation is generally a low-maintenance process, the risk of equipment-related injuries is minimized, making it an attractive option for industries with stringent safety requirements.

Applications of Magnetic Separation

Magnetic separation finds application in various industries, each benefitting from the technology in unique ways:

- Mining and Mineral Processing: To separate valuable minerals from ores, magnetic separation efficiently extracts iron and other ferromagnetic substances, improving the purity and value of the final product.

- Food and Agriculture: Magnetic separators are used to eliminate metallic contaminants in food products, ensuring consumer safety and meeting regulatory standards.

- Recycling: In recycling facilities, magnetic separation helps sort ferrous materials from non-ferrous ones, facilitating the recycling process and maximizing resource recovery.

- Pharmaceuticals and Chemicals: Magnetic separation helps purify ingredients by removing metal particles, safeguarding product quality and consumer health.

Disadvantages of Magnetic Separation

While magnetic separation offers numerous benefits, it is not without its limitations. Here are some potential disadvantages:

1. Limited to Magnetic Materials

One of the most obvious limitations is that magnetic separation can only separate materials that respond to a magnetic field. Non-magnetic materials, such as plastics, ceramics, and most types of glass, cannot be separated using this method. In processes that require the separation of multiple material types, additional separation techniques must be used alongside magnetic separation to achieve the desired results.

2. High Initial Equipment Costs

Magnetic separation systems, particularly high-strength magnetic separators, can require a substantial initial investment. Equipment costs vary depending on the strength of the magnets, the size of the unit, and its intended application. For small businesses or operations with limited budgets, the cost of purchasing and maintaining magnetic separation equipment may be a deterrent.

3. Specific Maintenance Requirements

Although magnetic separation is generally low-maintenance, certain types of magnetic separators, such as high-intensity or rare-earth magnets, require regular upkeep to maintain their effectiveness. Over time, magnetic materials can lose strength, and accumulated contaminants may reduce separation efficiency. Some separators may also require periodic cleaning and recalibration to ensure optimal performance.

4. Potential Impact on Non-Magnetic Components

In some cases, high-intensity magnetic fields can inadvertently affect non-magnetic components or interfere with nearby electronic equipment. Sensitive materials or electronics used in the vicinity of magnetic separation equipment may experience disruptions due to the magnetic field, potentially impacting equipment functionality and safety. This can be a concern in industries such as electronics or any setting with sensitive measurement devices.

5. Process Limitations

Certain applications require a high degree of separation accuracy, which magnetic separation may not always provide. For example, when working with extremely fine particles, magnetic separation may struggle to achieve the desired level of precision. This can limit its effectiveness in processes that require separation at a micro or nano-scale level, as magnetic forces may not be sufficient to separate ultra-fine particles consistently.

6. Challenges with Wet Separation

In some cases, magnetic separation is performed on wet materials, such as in mineral processing. While effective, wet magnetic separation can be challenging as it may require additional equipment to manage water flow and separation. The presence of water can complicate the separation process, potentially leading to clogging or inefficiencies. Additionally, handling wet materials can increase maintenance demands and create the need for drying processes afterward.

Overcoming the Disadvantages: Solutions and Alternatives

For industries looking to leverage magnetic separation but facing these limitations, a combination of strategies and alternative technologies can help address some of these challenges:

- Hybrid Separation Techniques: Combining magnetic separation with other techniques like gravity separation, flotation, or electrostatic separation can help achieve a more comprehensive separation process, especially in complex mixtures with both magnetic and non-magnetic particles.

- Investment in High-Efficiency Equipment: While the initial cost may be high, investing in high-quality magnetic separation equipment can provide long-term benefits, including lower maintenance costs and more consistent performance.

- Use of Advanced Magnet Materials: With the advent of neodymium magnets and other rare-earth materials, magnetic separators can achieve stronger magnetic fields, allowing for more effective separation, particularly in applications requiring fine particle separation.

Conclusion

Magnetic separation is a powerful and versatile tool used across industries for efficiently separating magnetic materials from non-magnetic ones. Its benefits include precise separation, cost-effectiveness, minimal environmental impact, and compatibility with automation, making it a valuable choice in various settings. However, magnetic separation is not without its challenges. Its effectiveness is limited to magnetic materials, and it may require significant upfront investment and specialized maintenance. For applications with demanding separation requirements or non-magnetic materials, combining magnetic separation with other methods can enhance its effectiveness and broaden its range of applications.

By understanding both the benefits and limitations of magnetic separation, industries can make informed decisions about how best to incorporate this technology into their processes, maximizing efficiency and achieving high-quality results.