Introduction to VCM Motors

Voice Coil Motors (VCM) are a type of electromechanical actuator that uses the principle of electromagnetism to generate motion. These motors are widely used in various industries due to their unique characteristics, including high precision, fast response time, and simple design. VCM motors are especially prevalent in applications that require linear motion or precise positioning.

In this article, we will explore the working principles of VCM motors, their applications, advantages, and limitations. We will also provide insights into their future trends and emerging uses across different industries.

What Is a VCM Motor?

A Voice Coil Motor (VCM) is a type of linear actuator that operates on the principle of Lorentz force. It consists of a coil of wire, usually housed in a permanent magnetic field, which generates a force when current is passed through the coil. This force creates linear motion, making VCM motors ideal for applications requiring precise, controlled movement.

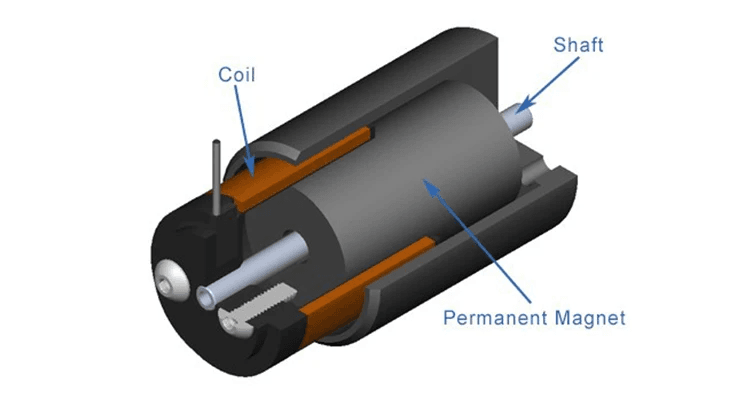

Basic Components of a VCM Motor

- Voice Coil: A coil of wire that moves in response to the current and the magnetic field.

- Permanent Magnet: A magnet that creates a fixed magnetic field in which the voice coil operates.

- Stator: The part of the motor that holds the permanent magnet and other supporting components.

- Commutator or Controller: In some designs, a controller regulates the direction and flow of current through the voice coil to control motion.

How Does a VCM Motor Work?

The Principle of Electromagnetism

VCM motors are based on the principle of electromagnetism. When an electrical current passes through the voice coil, it interacts with the magnetic field created by the permanent magnet, producing a force in the form of linear motion.

The force is determined by two factors:

- The amount of current flowing through the coil.

- The strength of the magnetic field.

By adjusting these parameters, the speed and position of the coil can be controlled with high precision, making VCM motors ideal for applications requiring accurate and smooth linear motion.

Operation Overview

- Magnetic Field Interaction: As current flows through the voice coil, it creates a magnetic field around it. The interaction between this field and the fixed magnetic field of the permanent magnet produces a force that moves the coil.

- Motion Control: The position of the coil can be finely controlled by adjusting the current applied to the voice coil. This allows for precise linear motion control with minimal mechanical components.

- Feedback Mechanism: Many VCM systems incorporate feedback sensors, such as Hall Effect sensors, to monitor the position of the voice coil. This ensures accurate movement and allows for real-time adjustments.

Applications of VCM Motors

VCM motors are versatile and find applications in various industries. Some of the most notable uses include:

1. Camera Autofocus Systems

One of the most well-known applications of VCM motors is in digital cameras and smartphones, where they are used in autofocus (AF) systems. The ability to move the lens quickly and accurately in and out of focus is essential for capturing sharp images, especially in high-resolution cameras. VCM motors are favored in these systems due to their quick response time and precision.

2. Hard Drive Actuators

In traditional hard disk drives (HDDs), VCM motors are used to position the read/write heads accurately over the disk platters. The precise linear motion provided by VCMs allows hard drives to store and retrieve data with high efficiency. Though solid-state drives (SSDs) are increasingly replacing HDDs, VCM motors remain critical in legacy systems.

3. Speakers and Audio Systems

VCM motors are used in speaker systems, particularly in the design of woofers and subwoofers. The voice coil is integral to the movement of the speaker cone, which generates sound. The ability to control the position of the cone with precision results in high-quality sound production, making VCMs essential components in high-performance audio equipment.

4. Robotics

In robotics, VCM motors are often used in applications that require fine motion control, such as robotic arms or surgical robots. The ability to achieve smooth, precise movements in real-time is critical for ensuring accuracy and safety in these applications.

5. Medical Equipment

VCM motors are used in various medical devices, such as MRI machines and medical imaging equipment, where precise positioning of components is required. In addition, VCMs are used in actuators for prosthetics and orthotics, providing a high degree of control over movement.

6. Industrial Automation

In manufacturing processes, VCM motors can be used in systems that require precise linear motion, such as conveyor belts, pick-and-place machines, and other automation systems. Their accuracy and speed make them suitable for applications that require fast and repeatable motion.

Advantages of VCM Motors

VCM motors offer a variety of benefits over other types of actuators, which is why they are so widely used in applications requiring precise control.

1. High Precision

VCM motors can provide extremely precise movement with minimal mechanical backlash. This is particularly beneficial in applications like autofocus systems, medical devices, and robotics, where even slight inaccuracies can have significant consequences.

2. Fast Response Time

VCM motors have a fast response time, meaning they can change the direction of motion quickly and with little delay. This makes them ideal for high-speed applications, such as autofocus in cameras and robotics.

3. No Physical Contact

Unlike traditional motors, which use brushes or gears to transfer motion, VCM motors rely on electromagnetic forces to generate movement. This results in less wear and tear, reducing the need for maintenance and increasing the lifespan of the motor.

4. Compact Design

VCM motors are relatively small and compact compared to other types of motors that provide similar performance. This makes them ideal for applications where space is limited, such as in smartphones, digital cameras, and medical devices.

5. Linear Motion

VCM motors produce linear motion directly, without the need for complex mechanical components like gears or linkages. This simplifies the design of systems that require straight-line movement, making the VCM motor an attractive option for many applications.

Limitations of VCM Motors

While VCM motors offer several advantages, they also have certain limitations:

1. Limited Force Output

VCM motors are best suited for applications that require precise, low-to-moderate force. They are not ideal for high-force applications, such as heavy lifting, where other types of motors like stepper motors or DC motors may be more appropriate.

2. Temperature Sensitivity

Like all motors, VCM motors can be affected by changes in temperature. Excessive heat can impact the efficiency of the motor or damage the components, especially the coil. Proper heat dissipation and cooling mechanisms are necessary to ensure optimal performance.

3. Size Constraints

While VCM motors are compact, their linear range of motion can be limited by their size. This means that for applications requiring longer strokes or larger movements, a different type of actuator may be needed.

Future Trends in VCM Motor Technology

As technology advances, VCM motors are likely to see further innovations. Here are a few trends to watch out for:

1. Miniaturization and Integration

With the growing demand for smaller and more efficient devices, VCM motors are becoming increasingly miniaturized. This will enable new applications in wearable devices, IoT (Internet of Things) devices, and other compact electronic systems.

2. Improved Efficiency

Ongoing research is focused on improving the energy efficiency of VCM motors. This will make them even more appealing for battery-powered devices like smartphones and drones, where battery life is crucial.

3. Advanced Control Systems

The integration of advanced control algorithms, such as machine learning and artificial intelligence, could further enhance the performance of VCM motors. These systems will allow for more precise control, real-time adaptation, and predictive maintenance.

Conclusion

Voice Coil Motors (VCM) are a critical technology in many industries, offering precision, fast response, and reliability in a compact design. Their wide range of applications, from camera autofocus systems to robotics and medical devices, highlights their versatility. While they have some limitations, their unique characteristics make them an indispensable component in numerous high-performance systems.

As technology continues to evolve, VCM motors will likely become even more advanced, opening up new possibilities for innovation across a variety of industries.

Related Products