Introduction

Neodymium magnets, known for their extraordinary strength and versatility, are essential components in numerous modern applications. However, these powerful magnets are prone to corrosion and physical wear, which can significantly impact their performance and longevity. To mitigate these issues, various coatings and platings are applied to protect the magnets. This article provides a comprehensive guide on the different coatings available for neodymium magnets, helping you determine which coating is best for your specific needs.

Understanding Neodymium Magnets

Before diving into the specifics of magnet coatings, it’s essential to understand the composition and characteristics of neodymium magnets. Neodymium magnets are a type of rare-earth magnet composed mainly of neodymium, iron, and boron (NdFeB). These magnets are the strongest commercially available permanent magnets, known for their high magnetic strength, making them ideal for applications ranging from electronics to industrial machinery.

Key Properties:

- High Magnetic Strength: Neodymium magnets offer the highest magnetic strength among all permanent magnets, making them suitable for compact and efficient designs.

- Brittleness: Despite their strength, neodymium magnets are brittle and prone to chipping and cracking if not handled carefully.

- Corrosion Susceptibility: The iron content in these magnets makes them susceptible to corrosion, particularly in humid or saline environments.

The Need for Coatings

Given their susceptibility to corrosion and physical wear, coatings are crucial for maintaining the durability and performance of neodymium magnets. The right coating can prevent rust, enhance mechanical durability, and even improve the magnet’s appearance.

Functions of Coatings:

- Corrosion Resistance: Protects the magnet from environmental factors like moisture, which can cause oxidation and rust.

- Mechanical Protection: Shields the magnet from physical damage such as scratches, chipping, or breaking.

- Aesthetic Enhancement: Improves the visual appeal of the magnets, which can be important in consumer-facing applications.

Common Coatings for Neodymium Magnets

Various coatings and platings are used to protect neodymium magnets, each with unique properties and benefits. Here, we explore the most common types:

1. Nickel (Ni) Plating

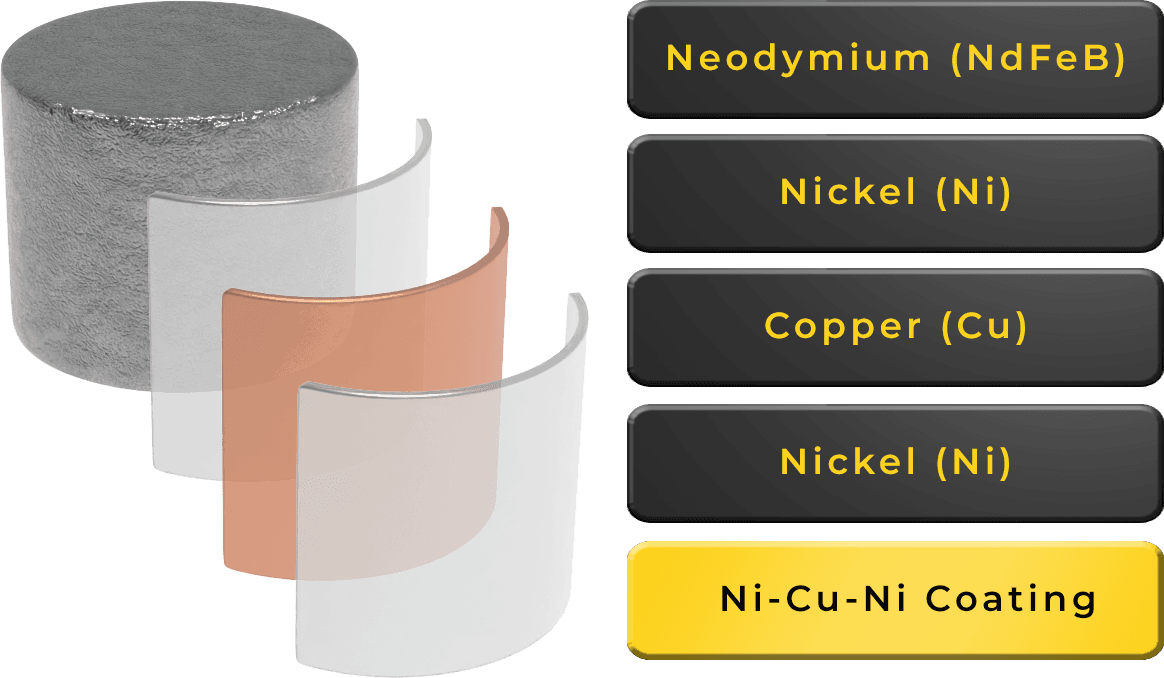

Overview: Nickel plating is one of the most widely used coatings for neodymium magnets. Typically, a layer of nickel is followed by a layer of copper and then another layer of nickel (Ni-Cu-Ni).

Advantages:

- Good Corrosion Resistance: The nickel coating provides a robust barrier against moisture and chemicals, reducing the risk of rust.

- Durable Finish: It offers good mechanical strength, protecting the magnet from scratches and minor physical impacts.

- Smooth and Lustrous Surface: Nickel plating enhances the magnet’s appearance, making it suitable for aesthetic applications.

Disadvantages:

- Limited Resistance to Harsh Environments: While effective in moderate conditions, nickel plating may not withstand prolonged exposure to extreme environments, such as those with high humidity or saltwater.

2. Zinc (Zn) Coating

Overview: Zinc is another common coating for neodymium magnets, often used as a more cost-effective alternative to nickel plating.

Advantages:

- Corrosion Resistance: Zinc provides decent protection against corrosion, particularly in indoor applications.

- Matte Finish: It gives the magnets a duller appearance, which can be desirable in certain industrial or low-profile applications.

- Cost-Effective: Zinc is generally less expensive than other coatings, making it a budget-friendly option.

Disadvantages:

- Less Durable: Zinc coatings are softer and less durable than nickel, making them more susceptible to wear and tear over time.

- Aesthetic Limitations: The matte finish may not be suitable for applications where appearance is a priority.

3. Epoxy Coating

Overview: Epoxy coatings involve applying a layer of epoxy resin over the magnet. This type of coating is known for its excellent protective qualities.

Advantages:

- Superior Corrosion Resistance: Epoxy provides an excellent barrier against moisture and chemicals, making it ideal for harsh environments.

- Impact Resistance: It offers good mechanical protection, shielding the magnet from physical damage.

- Variety of Colors: Epoxy coatings can be applied in various colors, allowing for customization based on aesthetic or functional needs.

Disadvantages:

- Thickness: Epoxy coatings are typically thicker than other types, which may not be suitable for applications where space is limited.

- Potential for Cracking: Epoxy can become brittle over time, especially under constant mechanical stress or extreme temperature changes.

4. Gold (Au) Plating

Overview: Gold plating is less common but is used in specialized applications where both corrosion resistance and biocompatibility are crucial.

Advantages:

- Exceptional Corrosion Resistance: Gold is highly resistant to oxidation and corrosion, making it suitable for critical applications.

- Biocompatibility: Gold plating is biocompatible, making it ideal for medical applications, including implants and devices that come into contact with the human body.

- Aesthetic Appeal: Gold provides a visually appealing finish, often used in luxury or decorative applications.

Disadvantages:

- High Cost: Gold is expensive, making it a costly option compared to other coatings.

- Softness: Gold is a soft metal and can wear off relatively easily under mechanical stress.

5. Phosphating

Overview: Phosphating is a chemical treatment that creates a protective layer on the surface of the magnet.

Advantages:

- Good Corrosion Resistance: It provides decent protection against corrosion, particularly in less demanding environments.

- Base for Additional Coatings: Often used as a base layer for other coatings, enhancing their adhesion and overall effectiveness.

Disadvantages:

- Limited Durability: Phosphate coatings are not as durable as metal platings or epoxy, making them less suitable for high-wear applications.

- Matte Finish: The finish is typically dull, which may not be aesthetically pleasing in visible applications.

Factors to Consider When Choosing a Coating

Selecting the appropriate coating for neodymium magnets depends on several factors, including the intended application, environmental conditions, and cost considerations. Here are key factors to consider:

Environmental Conditions: The operating environment significantly influences the choice of coating. For example, magnets used in marine environments require more robust corrosion resistance compared to those used in dry, indoor settings.

Mechanical Stress: Consider the amount of physical wear and tear the magnets will endure. Applications involving frequent handling or mechanical interaction may benefit from more durable coatings like nickel or epoxy.

Cost: Budget constraints often play a critical role in the decision-making process. While premium coatings like gold offer superior protection and aesthetics, they come at a higher cost. Balancing performance needs with budget limitations is crucial.

Aesthetic Requirements: In applications where the magnet is visible, the appearance of the coating may be important. For instance, gold or nickel coatings provide a more polished and attractive finish compared to matte options like zinc or phosphating.

Biocompatibility: For medical or food-related applications, the coating must be biocompatible and safe for contact with living tissues or food products. Gold plating is often preferred in such cases due to its biocompatibility.

Advanced Coating Technologies

Beyond traditional coatings, advanced technologies are being developed to enhance the performance and longevity of neodymium magnets. These innovations include nanocoatings, composite coatings, and multi-layered systems.

Nanocoatings

Overview: Nanocoatings involve applying ultra-thin layers of materials at the nanoscale. These coatings can provide superior protection with minimal impact on the magnet’s size and weight.

Advantages:

- Enhanced Protection: Nanocoatings can offer excellent resistance to corrosion and wear while maintaining the magnet’s original dimensions.

- Functional Properties: They can also impart additional functionalities, such as hydrophobicity or antibacterial properties.

Disadvantages:

- Complex Application Process: The application of nanocoatings requires sophisticated equipment and techniques, which can increase costs.

- Durability Concerns: While promising, the long-term durability of nanocoatings in various environments is still under study.

Composite Coatings

Overview: Composite coatings combine multiple materials to leverage the strengths of each. For example, a composite coating might include layers of metal plating with a polymer topcoat.

Advantages:

- Multi-Functional Protection: Composite coatings can provide comprehensive protection, combining corrosion resistance, mechanical durability, and aesthetic appeal.

- Customization: They allow for tailored properties to meet specific application needs.

Disadvantages:

- Cost: Composite coatings can be more expensive due to the complexity of materials and processes involved.

- Application Complexity: The application process can be more complex and time-consuming, requiring specialized techniques.

Multi-Layered Systems

Overview: Multi-layered coating systems involve applying several layers of different materials to achieve optimal protection and performance.

Advantages:

- Enhanced Durability: Each layer serves a specific function, such as adhesion, corrosion resistance, or wear protection, resulting in a highly durable coating.

- Customizable Properties: Layers can be customized to meet specific needs, such as improved thermal stability or electrical conductivity.

Disadvantages:

- Increased Thickness: Multi-layered systems can add significant thickness to the magnet, which may not be suitable for all applications.

- Cost and Complexity: The multi-layering process is often more costly and complex, requiring precise control during application.

Case Studies: Choosing the Right Coating for Specific Applications

To illustrate the practical considerations in selecting the best coating for neodymium magnets, let’s explore a few case studies:

Case Study 1: Marine Applications

Challenge: A company manufactures underwater robotics that use neodymium magnets for motor applications. The magnets are exposed to saltwater, which is highly corrosive.

Solution: The company chose an epoxy coating due to its superior corrosion resistance and durability in harsh environments. Additionally, they applied a nanocoating layer to enhance the magnet’s resistance to biofouling.

Outcome: The combination of epoxy and nanocoating provided long-lasting protection, significantly reducing maintenance costs and extending the lifespan of the magnets.

Case Study 2: Medical Devices

Challenge: A medical device manufacturer requires magnets for an implantable device. The magnets must be biocompatible and resistant to bodily fluids.

Solution: Gold plating was selected due to its excellent biocompatibility and corrosion resistance. The gold layer was thin to minimize any impact on the device’s size.

Outcome: The gold-plated magnets performed well within the human body, demonstrating no adverse reactions or degradation over time.

Case Study 3: Consumer Electronics

Challenge: A company producing high-end headphones needed magnets that were not only strong but also aesthetically pleasing and resistant to handling.

Solution: Nickel plating was chosen for its attractive finish and good corrosion resistance. The nickel layer also provided sufficient mechanical protection for the magnets during frequent handling.

Outcome: The nickel-plated magnets met the company’s aesthetic and durability requirements, contributing to the product’s premium feel and performance.

Custom Magnet Solutions

At MagnetsTek, we specialize in providing customized magnet solutions, including Custom Neodymium Magnets tailored to meet specific application needs. Whether you require magnets with particular coatings, shapes, or sizes, we work closely with you to deliver the optimal product. Our expertise also extends to Custom SmCo Magnets, offering high-performance options for demanding environments.

Why Choose Custom Magnets?

- Tailored Performance: Custom magnets ensure that the magnetic properties, coatings, and dimensions precisely match the application’s requirements.

- Enhanced Durability: By selecting the right coating and material, custom magnets offer improved durability and longevity.

- Specialized Applications: Customization allows for the development of magnets suited for specialized or unique applications, from medical devices to aerospace components.

Future Trends in Magnet Coating Technologies

The field of magnet coatings is continually evolving, with ongoing research and development aimed at enhancing performance, durability, and functionality. Some emerging trends and technologies include:

Smart Coatings

Overview: Smart coatings respond to environmental changes or stimuli, such as temperature, pH, or light. They can offer self-healing properties, where the coating repairs itself after being scratched or damaged.

Applications: Smart coatings could be particularly beneficial in environments where the magnets are subject to frequent physical damage or harsh conditions. They could also play a role in extending the lifespan of magnets in critical applications, such as aerospace or medical devices.

Eco-Friendly Coatings

Overview: With growing environmental concerns, there is an increasing demand for eco-friendly coatings. These coatings use sustainable materials and processes, minimizing environmental impact.

Applications: Eco-friendly coatings are ideal for applications where environmental sustainability is a priority. They are also increasingly preferred in industries facing stringent environmental regulations.

Conductive Coatings

Overview: Conductive coatings combine protective and conductive properties, allowing the magnets to participate in electrical circuits or shielding applications.

Applications: Conductive coatings are useful in electronic and electromagnetic shielding applications, providing both protection and functionality. They are also valuable in developing smart materials and devices that require integrated electrical and magnetic properties.

Conclusion

Choosing the right coating for neodymium magnets is crucial for ensuring their durability, performance, and suitability for specific applications. The ideal coating depends on various factors, including the operating environment, mechanical stress, cost, and aesthetic requirements.

Nickel and epoxy coatings are popular choices for their balance of cost and performance, offering good corrosion resistance and durability. Zinc coatings provide a cost-effective alternative, while gold plating is preferred for applications requiring biocompatibility and premium aesthetics. Phosphating, nanocoatings, composite coatings, and multi-layered systems offer additional options, each with unique advantages and limitations.

For those seeking tailored magnet solutions, MagnetsTek offers Custom Neodymium Magnets and Custom SmCo Magnets to meet diverse application needs. By understanding the specific requirements of your project and leveraging advanced coating technologies, we can help you choose the best magnet coating to maximize performance and longevity.

As technology advances, new coating materials and methods will continue to emerge, offering enhanced protection, functionality, and environmental benefits. Staying informed about these developments ensures that you can select the most appropriate solutions for your magnetic applications, ensuring optimal performance and longevity.