Neodymium magnets, known for their extraordinary strength and wide range of applications, are a staple in industries ranging from electronics to healthcare, automotive, and even energy generation. Despite their strength and durability, these magnets are highly susceptible to corrosion, which can significantly affect their performance and longevity. As a result, plating or coating neodymium magnets is a common practice. In this article, we will explore why most neodymium magnets are plated or coated, the types of coatings available, the benefits of coating, and how these processes affect the overall performance of the magnets.

1. Introduction to Neodymium Magnets

Neodymium magnets are a type of rare-earth magnet, made from an alloy of neodymium, iron, and boron (NdFeB). They are the strongest type of permanent magnet available commercially, with magnetic fields that can be up to 1,000 times stronger than ordinary iron-based magnets. Due to their powerful magnetic properties, neodymium magnets are used in a wide variety of applications, including motors, sensors, speakers, hard drives, MRI machines, and much more.

While neodymium magnets offer excellent performance, they are inherently brittle and vulnerable to corrosion. This is due to the composition of the magnet itself, as well as the fact that neodymium is a highly reactive metal. As a result, many manufacturers use coatings or plating to protect these magnets and enhance their lifespan.

2. The Need for Coating or Plating

The primary reason for coating or plating neodymium magnets is to prevent corrosion. Unlike other metals such as stainless steel, neodymium is highly susceptible to rust and oxidation when exposed to moisture or air. If left uncoated, neodymium magnets can lose their magnetic strength over time, as the corrosion can damage the magnetic material and reduce the overall performance of the magnet.

In addition to corrosion, uncoated neodymium magnets are also prone to mechanical damage, such as chipping and cracking, due to their brittle nature. The coating helps protect the magnet from both environmental factors and physical impact, ensuring the magnet maintains its structural integrity and magnetic properties for a longer period.

Moreover, the appearance of the magnet can be affected by corrosion. For products where aesthetics matter, such as in jewelry, magnets with a rusted or tarnished surface are undesirable. Coatings and plating provide a shiny, uniform surface that enhances the visual appeal of neodymium magnets.

3. Types of Coatings and Plating for Neodymium Magnets

There are several different types of coatings and plating techniques used to protect neodymium magnets. Each type offers distinct advantages depending on the application and environment in which the magnet will be used. Some of the most common types include:

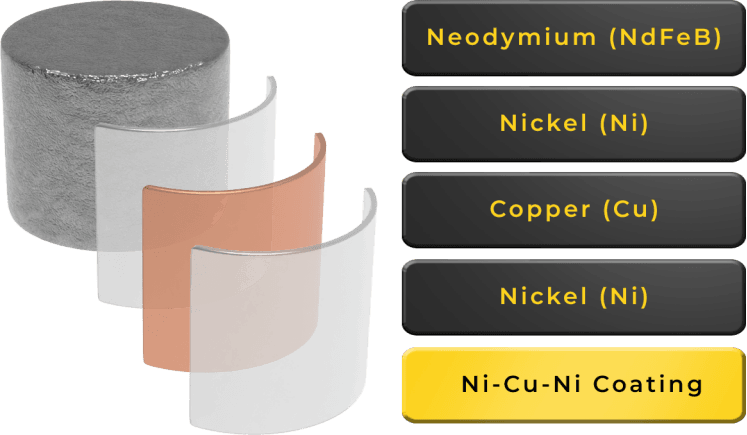

a. Nickel-Copper-Nickel (Ni-Cu-Ni) Plating

One of the most popular and widely used plating methods for neodymium magnets is the nickel-copper-nickel (Ni-Cu-Ni) plating process. This method involves plating a thin layer of copper between two layers of nickel. The copper layer acts as a corrosion-resistant barrier, while the nickel layers provide additional protection and enhance the magnet’s resistance to scratches and abrasions.

Nickel-copper-nickel plating is highly effective in preventing rust and oxidation. It also improves the magnet’s appearance by providing a shiny, metallic finish. This type of coating is commonly used for magnets in consumer electronics, automotive applications, and other industries where corrosion resistance is critical.

b. Zinc Plating

Zinc plating is another common method used to protect neodymium magnets. This process involves coating the magnet with a thin layer of zinc, which forms a protective barrier against moisture and air. Zinc plating is often used in industrial applications where magnets are exposed to harsher environments, such as marine or outdoor settings.

Zinc has excellent corrosion-resistant properties and provides an added layer of protection against wear and tear. However, zinc plating can be more prone to scratching compared to other coatings, so it is typically used in applications where aesthetic appearance is not as critical.

c. Epoxy Coating

Epoxy coating is a thick, durable, and highly protective coating that is often used for neodymium magnets. The epoxy resin provides excellent resistance to moisture, chemicals, and abrasion. This type of coating is ideal for magnets that will be exposed to harsh conditions, such as those used in industrial or medical applications.

Epoxy coatings are typically applied as a thick layer, offering superior protection against corrosion and physical damage. However, because of the thickness of the coating, epoxy coatings may reduce the magnet’s overall strength slightly. This is why epoxy coatings are often used for applications where corrosion protection is more important than maintaining maximum magnetic force.

d. Gold Plating

For applications where aesthetic appeal is important, such as in jewelry or high-end consumer products, gold plating is sometimes used on neodymium magnets. Gold plating provides a shiny, attractive finish that resists tarnishing and corrosion, making it ideal for decorative applications.

Gold-plated neodymium magnets tend to be more expensive due to the cost of the gold material. However, they offer excellent resistance to corrosion, while also providing a high-quality, visually appealing finish. Gold plating is less common than nickel or epoxy coatings but is used in specific markets where appearance is a priority.

e. Chrome Plating

Chrome plating is another popular option for coating neodymium magnets. Chrome is known for its hardness, resistance to corrosion, and smooth finish. Chrome-plated magnets are often used in applications where both durability and a high-quality finish are required. Like nickel plating, chrome plating provides a shiny surface that resists scratching and wear.

Chrome coatings are especially popular in automotive and tool industries, where the magnets need to withstand rough handling while maintaining a polished appearance. However, chrome coatings can sometimes be more expensive than other options like nickel or zinc.

4. Benefits of Coating Neodymium Magnets

The decision to plate or coat neodymium magnets is driven by several benefits that coatings provide, including:

a. Corrosion Resistance

As mentioned, neodymium magnets are highly prone to corrosion, especially when exposed to moisture or humid environments. Coating the magnets creates a protective layer that prevents rust and oxidation, preserving the magnet’s strength and effectiveness. Without this protective layer, the magnet may deteriorate rapidly, reducing its lifetime and performance.

b. Improved Durability

Neodymium magnets are brittle and prone to chipping or cracking, particularly during handling and transportation. A coating helps to reinforce the surface of the magnet, reducing the likelihood of physical damage. This is especially important for magnets used in demanding applications, where they may be subject to impact or mechanical stress.

c. Aesthetic Appeal

The appearance of neodymium magnets can be an important consideration, especially in consumer products. Coatings such as nickel or gold plating enhance the appearance of the magnet, giving it a smooth, shiny finish that is aesthetically pleasing. In some cases, the visual appeal of the magnet is just as important as its magnetic properties.

d. Extended Lifespan

Coated neodymium magnets generally last longer than uncoated magnets. The coating protects the magnet from environmental factors that can cause deterioration over time. This results in a longer operational life for the magnet, making it a more cost-effective option in the long term.

e. Enhanced Performance in Specific Environments

Certain coatings, such as epoxy or zinc, provide additional benefits in specific environments. For example, epoxy coatings offer excellent resistance to chemicals, while zinc plating provides extra protection in marine or outdoor environments. By selecting the appropriate coating, manufacturers can ensure the magnet performs optimally in various conditions.

5. Factors to Consider When Choosing a Coating

When selecting a coating or plating for neodymium magnets, there are several factors to consider:

- Environmental Exposure: Consider whether the magnet will be exposed to moisture, chemicals, or high temperatures. This will determine whether a coating like epoxy or zinc is more appropriate.

- Aesthetic Requirements: For consumer-facing products, aesthetics may play a significant role. Coatings like gold or chrome plating offer a visually appealing finish.

- Mechanical Stress: If the magnet will be subject to physical impact or wear, a more durable coating, such as nickel-copper-nickel or chrome, may be necessary.

- Cost: Coatings vary in cost, with options like gold plating being more expensive than nickel or zinc. Manufacturers must weigh the cost of coating against the benefits it provides.

6. Conclusion

Coating or plating neodymium magnets is an essential practice that ensures the magnets retain their performance, durability, and appearance over time. With the right coating, neodymium magnets can withstand harsh environments, physical impact, and corrosion, making them ideal for a wide range of applications. Whether you are using magnets in electronics, automotive, or decorative products, selecting the right coating is crucial for maximizing the lifespan and effectiveness of these powerful magnets.

Related: Neodymium Magnets Coatings