NdFeB (neodymium iron boron) magnets, often referred to as rare earth magnets, are among the strongest permanent magnets available. Their exceptional magnetic properties make them indispensable in industries ranging from consumer electronics to renewable energy. However, you may notice that many of these magnets come with chamfered edges. In this article, we will explore why NdFeB magnets are chamfered and the critical role chamfers play in their functionality and safety.

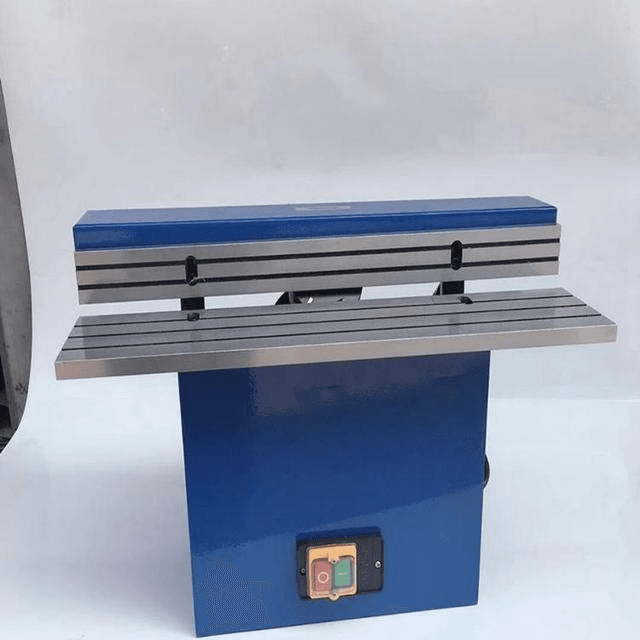

What Is Chamfering?

Chamfering is a machining process where edges or corners are beveled or rounded. Instead of leaving a sharp 90-degree angle, chamfering creates an angled or slightly rounded transition. The extent of chamfering can vary depending on the application and design requirements of the magnet.

This process is not exclusive to magnets—it is widely used in various industries to improve the structural, aesthetic, or functional qualities of a component.

Why Are NdFeB Magnets Chamfered?

1. Preventing Chipping and Cracking

NdFeB magnets are known for their strength, but they are also inherently brittle due to their material composition. The sharp edges of unchamfered magnets are highly prone to chipping and cracking during manufacturing, handling, or usage. Chamfering removes these vulnerable points, significantly reducing the risk of damage.

2. Enhancing Durability

By minimizing weak points on the magnet, chamfering increases its overall structural integrity. This enhancement is crucial in applications where magnets are exposed to mechanical stresses, such as motors or generators.

3. Improving Assembly Safety

The strong magnetic pull of NdFeB magnets can make handling challenging, particularly in industrial settings where magnets are paired in close proximity. Sharp edges increase the risk of injury during assembly or handling. Chamfered edges reduce this risk, making the magnets safer to work with.

4. Reducing Stress Concentration

Stress tends to concentrate around sharp corners and edges. In magnets subjected to physical forces or temperature changes, this can lead to failure. Chamfering helps distribute stress more evenly, enhancing the magnet’s performance and longevity.

5. Facilitating Easy Handling and Assembly

Chamfered edges allow magnets to slide into assemblies or slots more smoothly. This is especially important in precise applications such as magnetic couplings or sensors where alignment is critical.

What Does a Chamfer Do?

Chamfering serves multiple functions, each contributing to the magnet’s performance and usability:

1. Protects Against Wear and Tear

By smoothing out sharp edges, chamfering protects magnets from mechanical wear and abrasion. This is particularly beneficial in high-contact environments where magnets may rub against other surfaces.

2. Enhances Magnet Appearance

A chamfered edge not only improves functionality but also gives the magnet a polished and professional appearance. This is especially desirable in consumer-facing products like electronics.

3. Ensures Product Safety

Sharp edges can lead to cuts or punctures during handling. Chamfered magnets reduce these hazards, making them safer for users and operators.

4. Minimizes Magnetic Interference

Chamfering edges can slightly modify the magnetic field distribution at the magnet’s boundaries, ensuring smoother transitions in its magnetic flux. This adjustment can enhance performance in specific applications, such as electric motors or magnetic resonance imaging (MRI) systems.

5. Simplifies Packaging and Transport

Unchamfered magnets with sharp edges are more likely to damage each other or their packaging during shipping. Chamfered magnets are easier to stack, store, and transport without causing damage.

Applications Where Chamfering Is Essential

Chamfering is critical in various industries that rely on NdFeB magnets:

- Automotive Industry

- Used in electric vehicle motors where durability and precision are paramount.

- Aerospace

- Ensures safety and longevity in high-stress environments.

- Medical Equipment

- Magnetic components in MRI machines or surgical tools benefit from chamfering for safety and precision.

- Consumer Electronics

- Smartphones, headphones, and speakers require chamfered magnets for seamless assembly and aesthetic appeal.

- Renewable Energy

- Chamfered magnets improve the durability and reliability of wind turbine generators.

Conclusion

Chamfering NdFeB strong magnets is a vital process that enhances their durability, usability, and safety. By addressing challenges such as brittleness, stress concentration, and handling risks, chamfered edges ensure these powerful magnets can perform optimally in diverse applications. Whether used in cutting-edge technology or everyday devices, chamfering plays a subtle yet significant role in maximizing the potential of NdFeB magnets.

For high-quality NdFeB magnets with precision chamfering tailored to your needs, MetalsTek provides reliable solutions for industrial and commercial applications.