Introduction

Epoxy Magnets, a type of magnetic component featuring an epoxy resin coating, have become a critical solution in various marine applications. Their durability, resistance to harsh environmental conditions, and stable performance make them an ideal choice for use in marine environments. This article delves into why Epoxy Magnets are so widely used in marine equipment, detailing specific applications, comparing them with other magnetic solutions like NdFeB Magnets, and outlining the processes involved in manufacturing epoxy-coated magnets.

The marine environment imposes extreme challenges on materials, such as high salinity, continuous exposure to moisture, and fluctuating temperatures. For magnetic components, this environment presents an even more daunting test of performance and reliability. Epoxy Magnets rise to these challenges, ensuring efficient operation and long-term durability.

The Demands of Marine Equipment on Magnetic Materials

Marine equipment operates under some of the most demanding environmental conditions, which necessitate the use of robust and reliable materials. Magnetic components in marine equipment must meet several critical requirements:

- Corrosion Resistance: The high salt content in seawater accelerates the corrosion of conventional magnetic materials. Without effective protection, most magnets degrade quickly, leading to equipment failure.

- Mechanical Durability: Marine equipment often experiences intense vibrations and mechanical shocks from waves, currents, and operational stress. Magnetic components must resist wear and maintain their structural integrity under such conditions.

- Thermal Stability: Marine environments expose equipment to varying temperatures, from icy deep-sea conditions to the heat generated during operation. Magnets used in these environments need to maintain consistent performance across a wide temperature range.

- Longevity: Maintenance and replacement of components in marine applications are costly and time-consuming. Thus, materials that can withstand prolonged exposure to harsh conditions are essential.

Epoxy Magnets excel in meeting these demands, providing exceptional performance and durability. Their versatility and robustness make them indispensable in many marine applications.

Why Choose Epoxy Magnets?

Epoxy Magnets are primarily composed of high-performance NdFeB Magnets coated with a layer of epoxy resin. This combination offers several advantages:

Exceptional Corrosion Resistance

NdFeB Magnets are known for their strong magnetic properties but are highly susceptible to oxidation and corrosion. The epoxy coating forms a protective barrier, effectively shielding the magnet from exposure to saltwater and humidity. This makes Epoxy Magnets ideal for use in environments where corrosion is a significant concern, such as marine applications.

Enhanced Mechanical Strength

The epoxy layer not only protects the magnet from corrosion but also adds mechanical strength. This ensures the magnet can endure physical impacts and resist abrasion, making it suitable for equipment subjected to high levels of mechanical stress.

Thermal Stability

Epoxy Magnets are engineered to perform consistently over a wide temperature range. The combination of NdFeB’s inherent magnetic strength and the protective epoxy coating ensures reliable operation, even in fluctuating thermal conditions common in marine environments.

Eco-Friendliness

The epoxy coating used in these magnets is non-toxic and environmentally friendly, making them suitable for applications where environmental protection is a concern. Unlike untreated magnets, they do not release harmful substances into the surrounding marine ecosystem.

Cost-Effectiveness

Compared to other magnetic solutions with similar properties, Epoxy Magnets provide an excellent balance of performance and cost. Their long lifespan reduces the need for frequent replacements, resulting in lower overall maintenance expenses.

Applications of Epoxy Magnets in Marine Equipment

The versatility of Epoxy Magnets allows them to be used in a wide range of marine applications. Below are some of the most common uses:

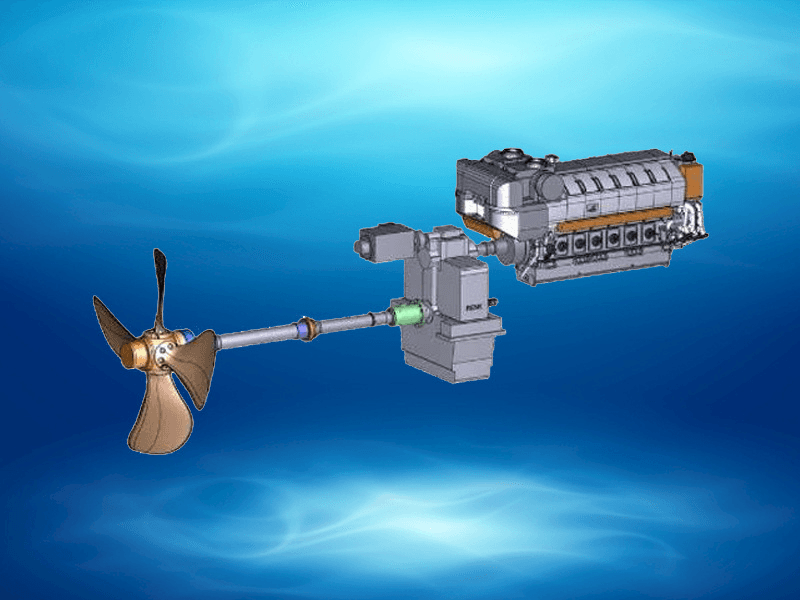

Ship Propulsion Systems

In modern ship propulsion systems, electric motors and magnetic components play a vital role. Epoxy Magnets are integral to motor assemblies, providing powerful magnetic fields while resisting the corrosive effects of saltwater. These magnets enable efficient energy transmission, contributing to the propulsion system’s overall performance. The protective epoxy layer ensures that the magnets remain operational even after prolonged exposure to seawater, significantly reducing maintenance costs. Furthermore, their robust construction helps them withstand mechanical stress and vibrations from the ship’s movement, enhancing the propulsion system’s durability and reliability.

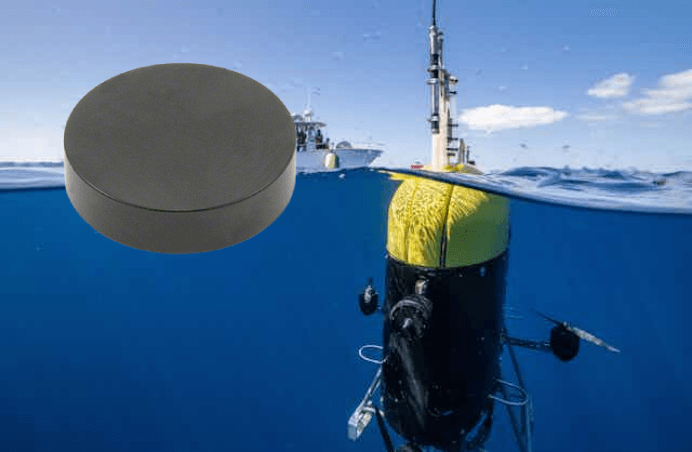

Marine Sensors

Sensors deployed in marine environments, such as depth gauges, temperature sensors, and salinity measurement devices, rely on magnetic components for their functionality. Epoxy Magnets are crucial in these applications due to their ability to maintain consistent magnetic properties under extreme conditions. For instance, in depth measurement devices, the magnets interact with electronic components to provide accurate readings even at great ocean depths. The epoxy coating prevents the magnets from degrading due to saltwater exposure, ensuring the sensors remain precise and functional over extended periods. This reliability is critical for oceanographic research and navigation systems, where accurate data is paramount.

Submersible Equipment

Underwater robots, autonomous underwater vehicles (AUVs), and remotely operated vehicles (ROVs) use Epoxy Magnets in their propulsion and manipulation systems. These magnets help these devices maintain high performance even under deep-sea pressure and extreme conditions.

Marine Energy Systems

Wave energy converters and tidal power generators utilize Epoxy Magnets in their designs. The magnets provide consistent magnetic force generation, ensuring optimal energy conversion efficiency while withstanding the harsh marine environment.

Water Treatment Systems

In desalination plants and water filtration systems used aboard ships or in offshore facilities, Epoxy Magnets help separate impurities and enhance filtration processes. Their corrosion resistance ensures long-term performance in high-salinity conditions.

Why Not Use Other Magnetic Materials?

Although alternatives to Epoxy Magnets, such as ceramic or ferrite magnets, exist, they come with significant drawbacks when applied in marine environments:

- Ferrite Magnets: These magnets offer good corrosion resistance but lack the magnetic strength required for high-performance marine applications. They are also brittle and more prone to mechanical failure.

- Uncoated NdFeB Magnets: While NdFeB Magnets are incredibly strong, their susceptibility to oxidation and corrosion makes them unsuitable for prolonged exposure to marine environments.

- Other Coated Magnets: While some magnets use nickel or zinc coatings, these materials can still corrode over time, especially in high-salinity conditions. Epoxy coatings, by contrast, offer superior and longer-lasting protection.

Epoxy Magnets combine the best of both worlds—the magnetic strength of NdFeB and the exceptional protective qualities of epoxy resin—making them the ideal choice for marine applications.

Processes to Manufacture Epoxy-Coated Magnets

The manufacturing of Epoxy Magnets involves several precise steps to ensure optimal performance and durability:

1. Selection of Base Material

The process begins with the selection of high-performance NdFeB Magnets, known for their exceptional magnetic strength. These magnets are produced through powder metallurgy, involving the pressing and sintering of NdFeB powder into the desired shape.

2. Surface Preparation

Before applying the epoxy coating, the surface of the magnet is thoroughly cleaned and polished. This step removes any contaminants or roughness, ensuring strong adhesion between the magnet and the epoxy layer.

3. Epoxy Coating Application

The magnets are coated with epoxy resin using techniques such as dipping, spraying, or electrostatic deposition. Each method ensures a uniform layer of epoxy resin that completely envelops the magnet, leaving no exposed areas susceptible to corrosion.

4. Curing Process

After the epoxy is applied, the coated magnets are cured at a specific temperature. This step hardens the epoxy layer, enhancing its protective properties and mechanical strength.

5. Quality Assurance

The finished Epoxy Magnets undergo rigorous testing to ensure they meet the required performance standards. This includes tests for:

- Corrosion resistance

- Adhesion strength

- Magnetic performance

- Dimensional accuracy

Conclusion

Epoxy Magnets have become indispensable in marine equipment due to their unmatched ability to withstand the harsh conditions of the marine environment. Their superior corrosion resistance, mechanical strength, and thermal stability make them an ideal choice for various applications, from ship propulsion systems to underwater robots and marine energy systems.

When compared to other magnetic materials, Epoxy Magnets emerge as a cost-effective, high-performance solution that addresses the unique challenges of marine environments. The meticulous manufacturing process ensures their reliability and durability, further solidifying their position as the go-to magnetic component for marine applications.

As technology advances and the demand for efficient marine solutions grows, Epoxy Magnets are poised to play an even more significant role, driving innovation and reliability in the field of marine engineering.