Introduction

Magnets are among the most versatile components in modern engineering, powering countless devices and systems across industries. From electric motors and sensors to renewable energy generators and medical instruments, magnets provide essential force, energy conversion, and sensing functions. While composition and grade are important factors in magnet design, the shape of a magnet is equally crucial. Shape influences magnetic field distribution, strength, alignment, and overall performance in a specific application.

In this article, we explore the most common magnet shapes, their unique properties, and how engineers leverage them in real-world applications. By understanding the role of shape, manufacturers and design engineers can make more informed decisions when specifying custom magnets for their projects.

Why Magnet Shape Matters

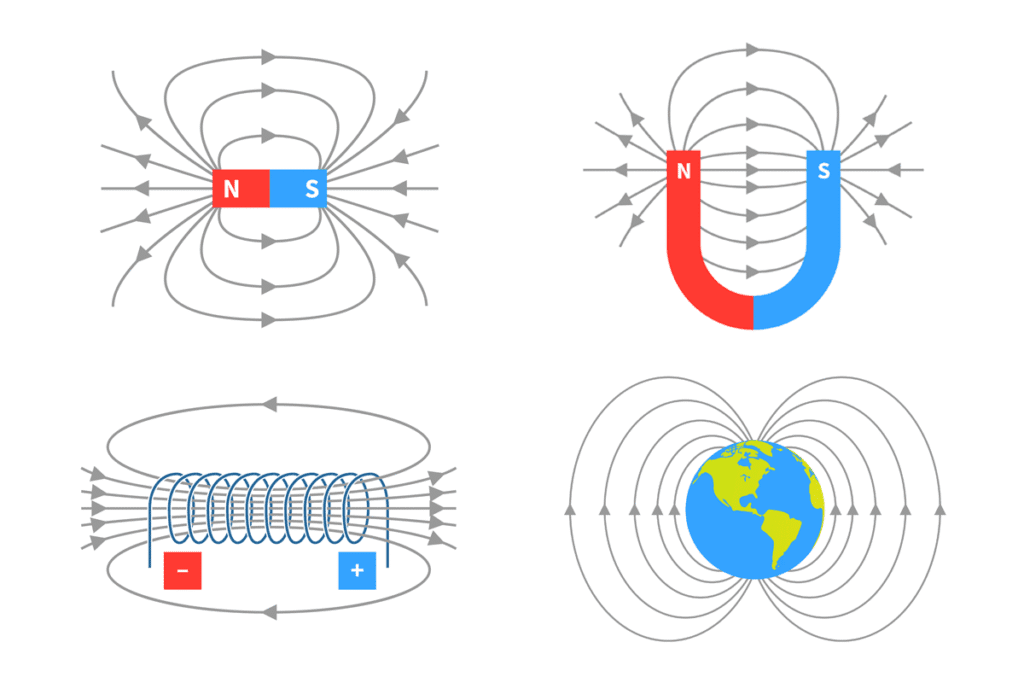

The shape of a magnet determines how its magnetic field lines emerge and interact with surrounding materials or components. A disc magnet produces a concentrated axial field, while a ring magnet generates a donut-shaped flux ideal for rotational devices. Similarly, arc magnets enable efficient motor geometries, while block magnets deliver broad holding force across flat surfaces.

Key engineering considerations include:

- Magnetic field distribution – affects precision, torque, and detection accuracy.

- Mounting compatibility – shapes must align with device geometry.

- Flux density – surface area and thickness influence effective strength.

- Thermal management – larger or specially shaped magnets may dissipate heat better.

- Cost and manufacturability – complex geometries may increase production costs.

Choosing the correct shape is therefore not just a design preference, but a performance-critical decision.

Common Magnet Shapes and Their Properties

1. Disc Magnets

Disc magnets are thin, round magnets with a high diameter-to-thickness ratio. They are among the most widely used shapes due to their versatility.

Key Features:

- Strong magnetic pull in axial direction

- Compact, easy to embed in assemblies

- Suitable for flat surface mounting

Applications:

- Sensors and detectors (Hall-effect sensors)

- Consumer electronics (smartphone speakers, microphones)

- Magnetic couplings in pumps

- Small motors and actuators

2. Ring Magnets

Ring magnets are essentially disc magnets with a central hole. The hole allows easy mechanical fastening, reducing the need for adhesives.

Key Features:

- Hollow design enables shaft mounting

- Uniform magnetic field distribution in rotational setups

- Excellent for torque transfer and rotary motion

Applications:

- Brushless DC motors (BLDC)

- Loudspeakers and headphones

- Magnetic resonance imaging (MRI) systems

- Clutch and coupling assemblies

3. Arc Magnets

Arc magnets are curved segments of a ring or cylinder. When multiple arc magnets are arranged together, they form a complete ring.

Key Features:

- Tailored for motor stators and rotors

- Generates efficient radial flux paths

- Available in varying arc lengths and angles

Applications:

- Electric motors (EV traction motors, servo motors)

- Generators and alternators

- Wind turbine systems

- Robotics and automation equipment

4. Block Magnets (Rectangular and Square)

Block magnets are rectangular or cubic in shape, offering large contact surfaces for magnetic holding.

Key Features:

- Strong surface pull force

- Easy to handle and integrate

- Cost-effective compared to custom shapes

Applications:

- Magnetic clamping in machining operations

- Magnetic separators for recycling and mining

- Structural holding in industrial fixtures

- Consumer products such as magnetic locks

5. Cylinder and Rod Magnets

Cylindrical magnets are longer than discs, producing deep magnetic penetration along their axis.

Key Features:

- Extended magnetic reach

- Excellent for insertion into drilled holes

- High aspect ratio provides stable fields

Applications:

- Magnetic stirring bars in chemical labs

- Sensors requiring deep flux penetration

- Positioning systems in medical devices

- Aerospace instruments where compact depth fields are needed

6. Sphere Magnets

Sphere magnets are less common but unique due to their omnidirectional field.

Key Features:

- Uniform magnetic flux in all directions

- Ideal for free rotational movement

- Limited holding force compared to flat surfaces

Applications:

- Educational models and demonstrations

- Magnetic bearings and rotary joints

- Toys and novelty products

- Specialized scientific instruments

7. Countersunk Magnets

These are disc or block magnets with a countersunk hole for screw mounting.

Key Features:

- Mechanical fastening ensures secure attachment

- Flush installation in assemblies

- Available in various diameters and depths

Applications:

- Furniture assembly

- Door catches and closures

- Industrial mounting systems

- Robotics where adhesives are unsuitable

8. Custom Shapes (Irregular & Complex Designs)

When standard geometries do not meet application requirements, magnets can be manufactured in custom shapes such as triangles, trapezoids, or highly specialized forms.

Key Features:

- Tailored magnetic flux distribution

- Matches unique design constraints

- Can combine multiple functions (holding + guiding)

Applications:

- Aerospace propulsion systems

- Miniaturized sensors in medical implants

- Automotive drive components with complex geometries

- Research and development projects

Engineering Applications by Industry

Automotive and Electric Vehicles

- Arc magnets in traction motors and regenerative braking systems

- Ring magnets in steering sensors and wheel speed sensors

- Block magnets for magnetic clamping in assembly lines

Consumer Electronics

- Disc magnets in microphones and camera modules

- Ring magnets in headphones and speakers

- Countersunk magnets in detachable connectors

Renewable Energy

- Arc magnets in wind turbine generators

- Cylinder magnets in linear actuators for solar trackers

Medical Devices

- Disc magnets in MRI machines

- Rod magnets in surgical tools and sensors

- Custom magnets in drug delivery devices

Industrial Automation

- Block magnets in magnetic lifters and conveyors

- Ring magnets in servo motors

- Custom arc magnets in robotics joints

Factors Influencing Magnet Shape Selection

When engineers select a magnet shape, they consider:

- Magnetic performance requirements (torque, holding force, sensing precision)

- Mechanical integration (fit with shafts, housings, or flat surfaces)

- Thermal and environmental conditions (temperature, corrosion resistance)

- Cost-efficiency (standard vs. custom shapes)

- Production feasibility (machining limits, coating requirements)

Future Trends in Magnet Shapes

As industries demand higher performance and miniaturization, magnet shapes will continue to evolve:

- 3D-printed magnets enabling freeform geometries

- Segmented arc designs for advanced EV motors

- Hybrid assemblies combining multiple shapes in one component

- Miniaturized custom shapes for biomedical implants and wearable electronics

Conclusion

Magnet shape is a critical design factor that directly impacts the performance and reliability of engineering systems. From the simplicity of disc magnets to the complexity of custom arc geometries, each shape serves a distinct purpose. By selecting the right magnet shape, engineers can optimize efficiency, reduce costs, and unlock new possibilities in applications ranging from electric vehicles to medical technologies.

At Magnetstek, we specialize in providing custom neodymium magnets in a wide range of shapes and configurations, tailored to the precise needs of your project. Whether you require standard geometries or complex custom designs, our expertise ensures that your application achieves maximum performance.

FAQ

Q1: Which magnet shape is best for motors?

Arc magnets and ring magnets are commonly used in motors due to their efficient radial flux paths.

Q2: Why do speakers use ring magnets?

Ring magnets provide uniform fields that interact well with coils, producing clear sound with minimal distortion.

Q3: Can I request custom-shaped magnets?

Yes. Manufacturers like Magnetstek can design and supply custom magnets to match specific application requirements.

Q4: Are block magnets stronger than disc magnets?

Not inherently. Strength depends on material grade, size, and surface area. Block magnets often provide stronger holding force on flat surfaces.

Q5: What is the most versatile magnet shape?

Disc magnets are considered the most versatile due to their compact size and wide application range.