In today’s rapidly advancing technological landscape, the interaction between magnetic fields and metals has become an area of both scientific intrigue and industrial innovation. One particularly interesting topic is the impact of magnets on aluminum alloys. Although aluminum is well known for its lightweight, high strength, and corrosion resistance, its behavior under the influence of magnetic fields reveals a complex interplay of physics and engineering. In this article, we will explore the fundamental science behind these interactions, discuss how they are applied in modern technologies, and highlight some of Magnetstek’s cutting-edge magnetic products that can be integrated with aluminum alloys for advanced applications.

Understanding Aluminum Alloys

Aluminum alloys are materials in which aluminum is combined with other elements—such as copper, magnesium, silicon, and zinc—to enhance its properties. The resulting alloys offer improved strength, durability, and versatility. Widely used in aerospace, automotive, construction, and consumer electronics, aluminum alloys are prized for their excellent mechanical properties and light weight.

Key Characteristics of Aluminum Alloys

- Lightweight and Strong: Aluminum alloys provide a high strength-to-weight ratio. This makes them ideal for applications where reducing weight is essential without compromising structural integrity.

- Corrosion Resistance: Aluminum naturally forms a thin oxide layer that protects it from corrosion, making it highly durable even in harsh environments.

- High Thermal Conductivity: This property makes aluminum alloys perfect for applications involving heat dissipation.

- Non-Ferromagnetic Nature: Unlike iron or steel, aluminum is not ferromagnetic. This means it does not become magnetized in the same way, a characteristic that plays a crucial role in its interaction with magnetic fields.

Despite aluminum’s non-ferromagnetic nature, its conductivity allows it to interact with changing magnetic fields in intriguing ways, such as the generation of eddy currents—a subject we’ll explore in detail later.

A Primer on Magnetism and Magnetic Materials

Magnets are objects that produce a magnetic field, an invisible force that can attract or repel other magnetic materials. There are several types of magnets, including permanent magnets (like neodymium and ferrite magnets) and electromagnets.

Permanent Magnets

Permanent magnets, such as Neodymium Magnets and Ferrite Magnets, are known for their strong magnetic fields. They retain their magnetism over time and are used in countless applications—from motors and generators to magnetic fasteners.

Electromagnets

Electromagnets generate a magnetic field only when an electric current passes through them. Their strength can be varied by controlling the current, making them versatile for many applications, including electromagnetic braking and magnetic resonance imaging (MRI).

Understanding how magnets work is essential for grasping how they affect non-magnetic materials like aluminum alloys. Although aluminum does not respond to magnets in the way that iron does, its high electrical conductivity means that it interacts with magnetic fields through electromagnetic induction—a phenomenon that underpins many modern technologies.

The Interaction Between Magnets and Aluminum Alloys

Even though aluminum alloys are not magnetically “active” in the same way as ferromagnetic materials, they still exhibit interesting behaviors when exposed to magnetic fields. This interaction is governed primarily by the principle of electromagnetic induction.

Electromagnetic Induction and Eddy Currents

When a magnetic field changes near a conductive material, it induces circulating currents called eddy currents within that material. According to Faraday’s Law of Electromagnetic Induction, these currents are generated in response to the changing magnetic flux. In aluminum alloys, which are excellent conductors, this can lead to several observable effects:

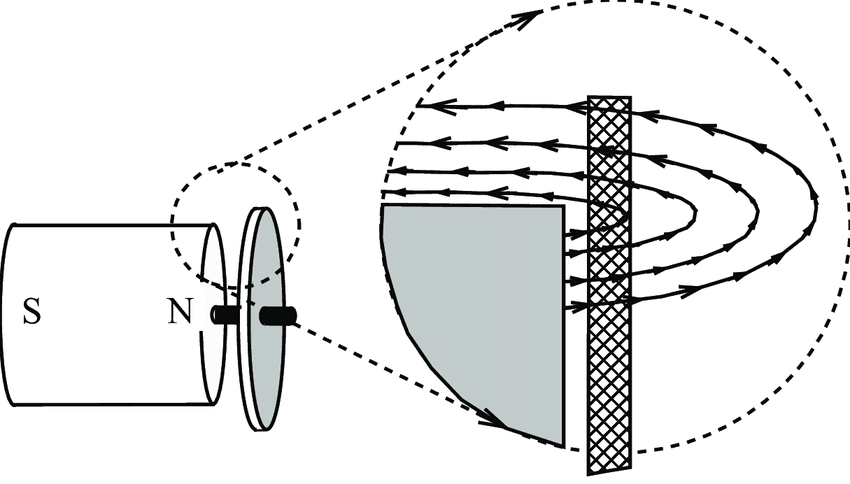

- Eddy Currents as a Damping Mechanism: As eddy currents flow within the aluminum, they create their own magnetic fields that oppose the change in the original magnetic field. This opposition can lead to a damping effect that slows down or resists motion. In practical applications, this is the principle behind electromagnetic braking systems.

- Heat Generation: The flow of eddy currents can cause localized heating within the material due to the resistance encountered by the electrons. Although aluminum’s resistance is relatively low, in high-power applications or rapid magnetic field changes, the resulting heat can be significant. This is why induction heating—a process used for metal hardening and melting—relies on this very phenomenon.

Magnetic Shielding and Eddy Current Losses

Due to the eddy currents induced in aluminum alloys, these materials can also exhibit a type of magnetic shielding. When a magnet is brought close to an aluminum alloy, the induced currents create magnetic fields that oppose the external field, effectively “shielding” parts of the material from the magnetic influence. This effect is often harnessed in applications where it is necessary to control or confine magnetic fields.

However, eddy currents also represent a form of energy loss. In situations where efficiency is paramount—such as in electric motors and transformers—the unwanted heating and energy loss from eddy currents must be mitigated. Engineers often design components with laminations or use materials with lower conductivity to reduce these losses.

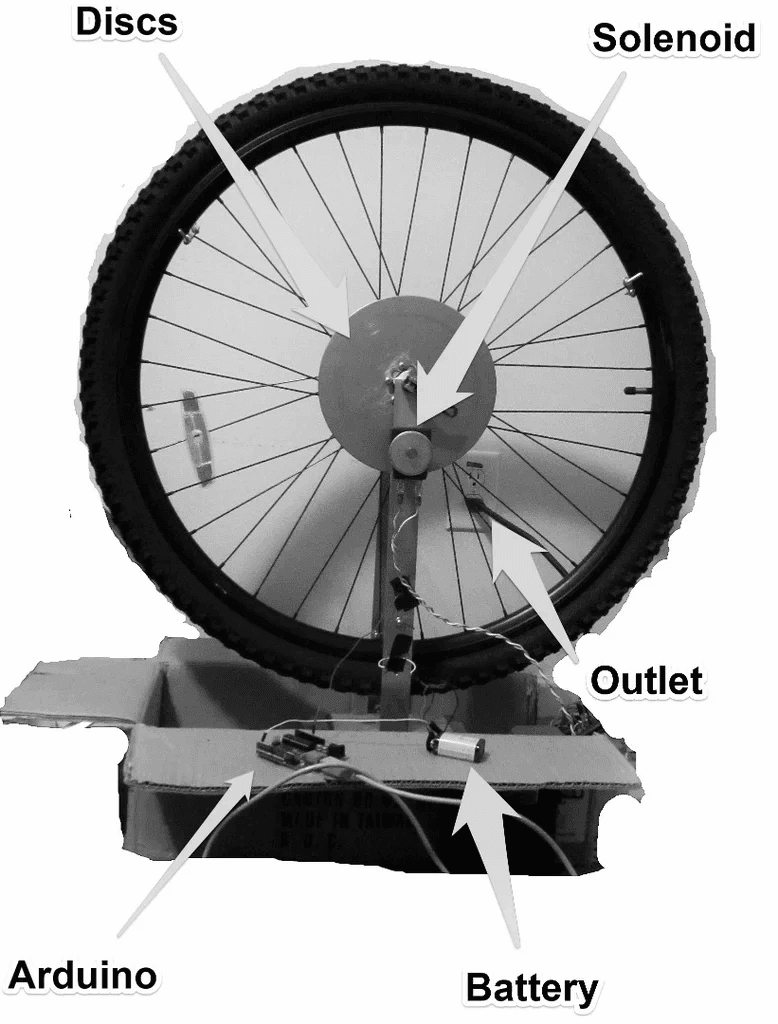

Practical Example: Electromagnetic Braking

One clear example of the interaction between magnets and aluminum alloys is electromagnetic braking. In these systems, a moving aluminum component is brought near a magnetic field. The rapid change in the magnetic environment induces eddy currents in the aluminum, which in turn produce magnetic fields that oppose the motion. This opposition acts as a braking force without any physical contact between the components, leading to smooth, wear-free operation.

Electromagnetic braking is used in applications ranging from roller coasters to high-speed trains and even industrial machinery. The advantage of using aluminum alloys in these applications lies in their lightweight nature and excellent conductivity, which maximizes the eddy current effects for efficient braking.

Applications of Magnet-Aluminum Alloy Interactions

The interplay between magnets and aluminum alloys has led to a wide variety of applications across several industries. Let’s explore some of these applications and see how they translate into real-world benefits.

Electromagnetic Braking and Damping Systems

Electromagnetic braking systems leverage the eddy current effect in aluminum alloys to provide non-contact braking. As a magnet passes near an aluminum component, the induced eddy currents create opposing forces that slow down motion. This type of braking system is especially valued in environments where traditional friction-based brakes would cause wear and require frequent maintenance. For example, some high-speed trains and amusement park rides use electromagnetic brakes to ensure smooth deceleration.

Induction Heating for Industrial Processing

Induction heating is a process where alternating magnetic fields are used to induce currents in a conductive material, generating heat without direct contact. Aluminum alloys, thanks to their excellent conductivity, are often used in applications that require rapid and localized heating. This method is widely used in metal forging, welding, and heat treatment processes. The ability to control the heating process precisely has made induction heating a critical technology in modern manufacturing.

Magnetic Sensors and Non-Destructive Testing

The interaction between magnetic fields and aluminum alloys also forms the basis for certain magnetic sensors and non-destructive testing (NDT) methods. For instance, Magnetic Sensors can detect subtle changes in magnetic fields, which can be used to monitor structural integrity or detect defects in aluminum components. These sensors are essential in aerospace, automotive, and infrastructure applications, where safety and reliability are of utmost importance.

Energy Harvesting and Wireless Charging

Another emerging application is energy harvesting, where the movement of aluminum alloys in varying magnetic fields can be used to generate electrical energy. This concept is the basis for some wireless charging systems and energy recovery devices. By capturing the energy from induced eddy currents, engineers can develop systems that power small electronic devices or sensors without the need for direct electrical connections.

Magnetic Separation in Recycling

In recycling operations, separating aluminum from other metals is crucial for efficient processing. Magnets, although they do not directly attract aluminum due to its non-ferromagnetic nature, can be used in conjunction with eddy current separators. These machines use a high-speed rotating magnetic field to induce currents in non-magnetic metals like aluminum. The resulting forces cause the aluminum pieces to be ejected from the magnetic field, effectively separating them from other materials. This technology is pivotal in improving the recycling process and reducing waste.

The Role of Product Innovations at Magnetstek

At Magnetstek, we are committed to harnessing the power of magnetism to drive innovation across various industries. Our product portfolio is designed to meet the demanding requirements of modern applications where magnetic fields interact with materials like aluminum alloys. Let’s take a closer look at some of our key product categories, along with direct links for further exploration:

1. Neodymium Magnets

Description: Renowned for their exceptional strength, Neodymium Magnets are a critical component in many high-performance systems. Their ability to generate strong magnetic fields makes them ideal for applications such as magnetic separation, motors, and sensors.

Product Link: Neodymium Magnets

2. Ferrite Magnets

Description: Ferrite Magnets offer a cost-effective solution with reliable performance. They are widely used in applications that do not require the high magnetic strength of neodymium magnets, including consumer electronics and electromagnetic interference (EMI) shielding.

Product Link: Ferrite Magnets

3. Magnetic Sensors

Description: Our advanced magnetic sensors are designed to detect subtle changes in magnetic fields. They are integral in monitoring systems for non-destructive testing, industrial automation, and energy harvesting.

Product Link: Magnetic Sensors

4. Magnetic Assemblies

Description: Combining various magnetic components into a unified system, our magnetic assemblies are engineered for precision and durability. They are ideal for complex applications that demand tailored magnetic configurations, such as in electromagnetic braking and induction systems.

Product Link: Magnetic Assemblies

5. Custom Magnetic Solutions

Description: At Magnetstek, we understand that every application has unique requirements. Our custom magnetic solutions allow you to design and implement magnetic systems that perfectly meet your specific needs, from prototyping to large-scale production.

Product Link: Custom Magnetic Solutions

By integrating our products with aluminum alloys, engineers can develop innovative systems that leverage the unique benefits of both materials. For instance, using Neodymium Magnets in conjunction with aluminum components can enhance electromagnetic braking performance, while magnetic sensors can monitor the interaction between magnetic fields and aluminum in real-time.

Our commitment to quality and innovation has made Magnetstek a trusted partner in industries ranging from automotive and aerospace to industrial automation and renewable energy. With a focus on cutting-edge research and development, we continue to push the boundaries of what is possible with magnetism and conductive materials.

The Science Behind the Interaction

The phenomenon that drives the interaction between magnets and aluminum alloys is rooted in fundamental electromagnetic principles. Here’s a closer look at the physics involved:

Faraday’s Law of Electromagnetic Induction

Faraday’s Law is a cornerstone of electromagnetism. It states that a change in the magnetic environment of a conductor will induce an electromotive force (EMF) in the conductor. In aluminum alloys, the rapid change in the magnetic field produced by a moving magnet induces eddy currents. These currents, in turn, generate their own magnetic fields that oppose the original magnetic field according to Lenz’s Law.

Lenz’s Law

Lenz’s Law explains that the induced current will always flow in a direction that opposes the change causing it. In practical terms, when a magnet is brought near an aluminum alloy, the eddy currents generated will produce magnetic fields that work to cancel out the external field. This opposition is what leads to phenomena such as electromagnetic braking, where the motion of the aluminum component is slowed down without any physical contact.

Thermal Effects and Energy Dissipation

While eddy currents can be harnessed for beneficial purposes, they also dissipate energy in the form of heat. In industrial processes like induction heating, this effect is exploited to rapidly heat aluminum alloys for subsequent shaping or hardening. The key is balancing the desired electromagnetic effect with the need to control thermal energy to prevent damage to the material.

Practical Implications for Engineering

The interplay between magnetic fields and aluminum alloys requires careful engineering consideration. Designers must account for factors such as:

- Eddy Current Density: High conductivity in aluminum means that even moderate magnetic field changes can produce significant eddy currents.

- Component Geometry: The shape and thickness of aluminum parts influence the distribution of eddy currents and the resulting magnetic forces.

- Frequency of Magnetic Field Variation: The rate at which the magnetic field changes can affect the magnitude of induced currents, thereby influencing both braking forces and heating effects.

Understanding these principles allows engineers to tailor the interaction between magnets and aluminum alloys for specific applications—whether it’s optimizing the performance of an electromagnetic brake or ensuring the uniform heating of an aluminum component in an induction furnace.

Real-World Examples and Case Studies

To better appreciate the impact of magnets on aluminum alloys, let’s consider a few real-world examples:

Electromagnetic Braking in High-Speed Trains

In high-speed rail systems, electromagnetic braking systems are crucial for ensuring safe and smooth deceleration. An array of powerful magnets is positioned near aluminum alloy brake discs. As the train slows, the changing magnetic field induces eddy currents in the discs, creating opposing magnetic fields that resist the motion. This results in a controlled, contactless braking mechanism that reduces mechanical wear and enhances passenger comfort.

Induction Heating in Automotive Manufacturing

Modern automotive manufacturing often employs induction heating to treat aluminum components during assembly. Using precisely controlled magnetic fields, eddy currents are induced in aluminum parts, generating heat that allows for rapid processing without physical contact. This non-invasive technique is not only efficient but also improves product quality by ensuring uniform temperature distribution.

Energy Harvesting for Sensor Networks

Energy harvesting systems can capture the kinetic energy of moving aluminum components in varying magnetic fields. For instance, in industrial machinery, vibrations and movements create fluctuating magnetic fields around aluminum housings. Specialized Magnetic Sensors can harness this energy to power wireless sensor networks, enabling continuous monitoring without the need for external power sources.

Magnetic Separation in Recycling Facilities

Recycling facilities benefit from the use of eddy current separators. In these systems, a rotating magnetic field induces eddy currents in mixed metal waste streams. The aluminum components, being non-ferromagnetic, experience forces that separate them from other ferromagnetic materials. This separation process enhances recycling efficiency and helps reduce environmental impact.

Challenges and Considerations

While the interaction between magnets and aluminum alloys offers many advantages, it also presents certain challenges:

Managing Eddy Current Losses

In applications such as electric motors or transformers, eddy current losses can lead to unwanted heating and reduced efficiency. Engineers often mitigate these losses by designing components with thin laminations or using composite materials that reduce current flow.

Thermal Management

Since eddy currents can produce significant heat, especially under rapid magnetic field variations, managing the thermal profile of aluminum components is essential. Advanced cooling techniques or periodic rest cycles may be required to maintain optimal performance and prevent overheating.

Material Compatibility

When designing systems that integrate magnets with aluminum alloys, it is critical to consider the compatibility of materials. The magnetic field strength, frequency of operation, and environmental conditions all influence the overall performance and durability of the system. Comprehensive testing and simulation are often necessary to ensure that the final design meets both functional and safety requirements.

Future Trends and Research Directions

As technology continues to evolve, the study of how magnets affect aluminum alloys is likely to expand, leading to new applications and innovations. Here are a few future trends that are already emerging:

Advancements in Material Science

Researchers are continually developing new aluminum alloys with tailored properties, including improved conductivity and controlled microstructures. These advancements could further enhance the benefits of eddy current induction and reduce unwanted energy losses in practical applications.

Integration of Smart Sensors

The integration of smart sensors into aluminum components can provide real-time feedback on the effects of magnetic fields. By monitoring temperature, magnetic field strength, and current distribution, engineers can optimize system performance and quickly identify any issues. Our Magnetic Sensors are at the forefront of this technology, enabling smarter, more efficient systems.

Renewable Energy Applications

In the renewable energy sector, the interaction between magnets and aluminum alloys is already proving useful in energy harvesting and storage applications. For example, regenerative braking systems in electric vehicles utilize electromagnetic induction to recover kinetic energy, while new energy storage devices capture and store energy generated by fluctuating magnetic fields.

Customized Magnetic Solutions

The growing demand for specialized applications means that off-the-shelf solutions may no longer suffice. Manufacturers are increasingly turning to custom magnetic solutions to meet their exact specifications. At Magnetstek, our Custom Magnetic Solutions are designed to address the unique challenges of each project, ensuring optimal performance and reliability.

Conclusion

The impact of magnets on aluminum alloys is a multifaceted topic that blends fundamental physics with practical engineering applications. Despite aluminum’s non-ferromagnetic nature, its excellent conductivity allows it to interact with magnetic fields in ways that can be both beneficial and challenging. From the generation of eddy currents that enable electromagnetic braking and induction heating to the development of smart sensor networks and recycling technologies, the interplay between magnets and aluminum is at the heart of many modern innovations.

At Magnetstek, we are proud to offer a range of products designed to harness the power of magnetism in conjunction with aluminum alloys. Whether you’re looking for high-performance Neodymium Magnets, reliable Ferrite Magnets, advanced Magnetic Sensors, or integrated Magnetic Assemblies, our portfolio is engineered to meet the diverse needs of modern industry. Our custom solutions ensure that you receive the perfect combination of magnetic performance and material compatibility for your specific application.

Understanding how magnets influence aluminum alloys not only deepens our appreciation for the underlying science but also paves the way for innovative applications that drive the future of technology. As research continues and new materials are developed, we can expect even more exciting advancements that will further integrate the world of magnetism with everyday industrial processes.

Whether you are involved in automotive manufacturing, aerospace design, renewable energy systems, or any industry where aluminum alloys play a crucial role, the science of magnetic interaction offers valuable insights and tools for improving efficiency, safety, and performance. With Magnetstek’s innovative products and solutions, you are well-equipped to take advantage of these phenomena and transform your ideas into reality.

Embrace the dynamic interplay between magnets and aluminum alloys and join us at Magnetstek as we explore the cutting edge of magnetic technology. For more information on our products and how they can benefit your applications, please visit our product pages:

Together, we can unlock new possibilities and drive forward the innovations of tomorrow.