Introduction

In the world of magnetic innovation, there’s a silent hero that’s transforming industries and propelling advancements across various fields: the Arc Magnet. This powerful and versatile component, particularly in its Neodymium form, is making waves in technology, manufacturing, and beyond. But what exactly is an Arc Magnet, and why is it garnering so much attention? In this article, we’ll unlock the secrets behind these magnetic marvels, explore their myriad applications, and show you how Custom Neodymium Magnets can be tailored to meet your specific needs. Get ready to dive deep into the fascinating world of Arc Magnets and discover how they’re reshaping our future.

What Are Arc Magnets?

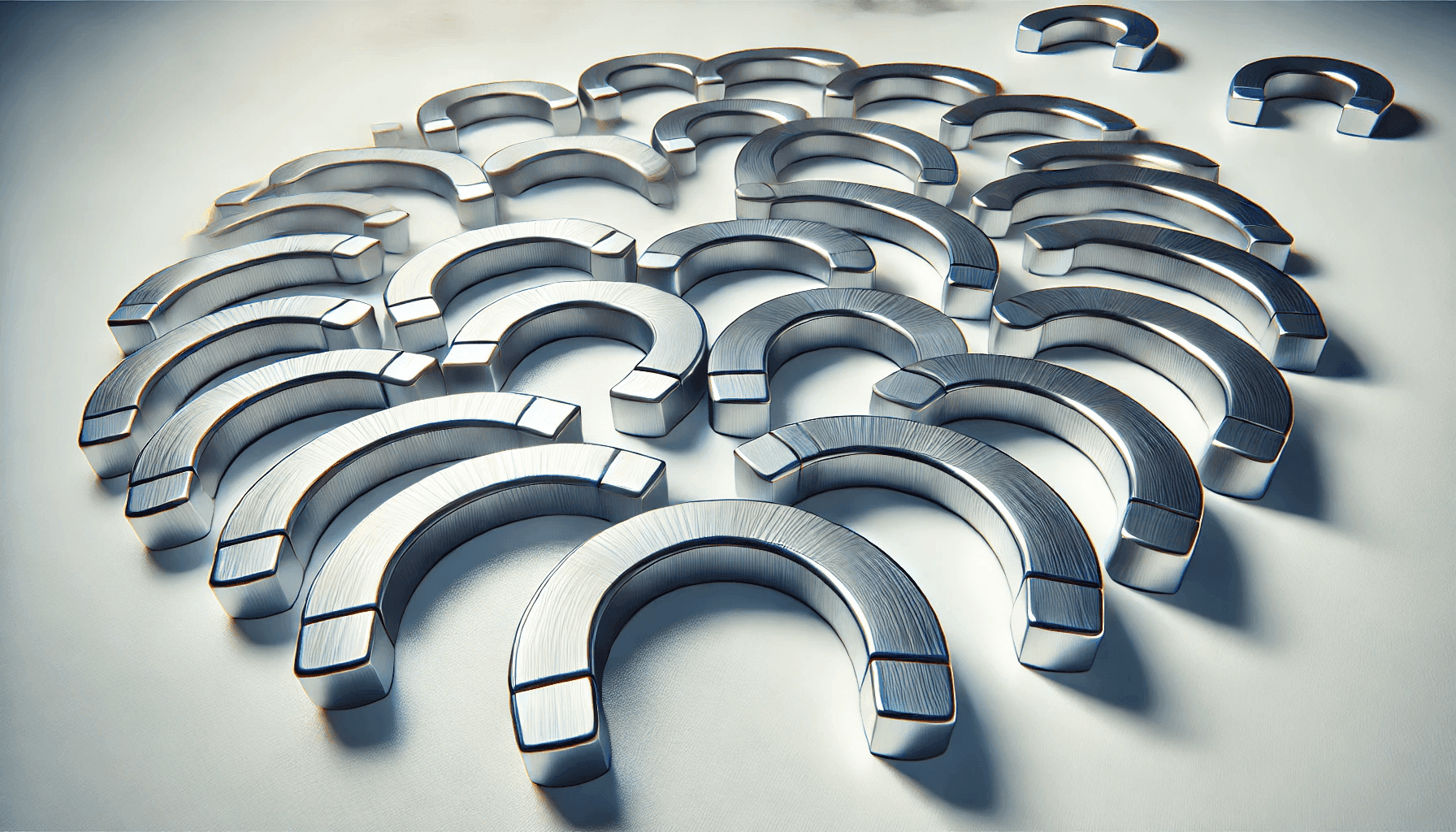

Arc Magnets, often referred to as Arc Segment Magnets, are a type of permanent magnet with a curved or arc shape. This design allows them to fit snugly around cylindrical surfaces or inside circular assemblies, making them incredibly versatile for a wide range of applications. Neodymium Arc Magnets, in particular, are known for their exceptional strength and durability. Made from an alloy of neodymium, iron, and boron (NdFeB), these magnets are the most powerful type of permanent magnet commercially available today.

The Power of Neodymium Arc Magnets

Neodymium Arc Magnets are prized for their unparalleled magnetic strength. This makes them ideal for applications where a strong, compact magnetic field is required. Their unique shape allows them to generate a focused magnetic field, making them perfect for use in electric motors, generators, and other rotational devices. The strong magnetic force of Neodymium Arc Magnets ensures efficient performance and enhances the overall functionality of these devices.

Applications of Arc Magnets

Arc Magnets find applications in a variety of fields, from industrial manufacturing to high-tech innovations. Here are some of the key areas where these powerful magnets are making a significant impact:

1.Electric Motors and Generators: The curved shape of Arc Magnets allows them to fit perfectly into the stators and rotors of electric motors and generators, enhancing their efficiency and performance.

2.Magnetic Bearings: Arc Segment Magnets are used in magnetic bearing systems to provide frictionless motion, reducing wear and tear and extending the lifespan of the equipment.

3.Magnetic Resonance Imaging (MRI): The precision and strength of Neodymium Arc Magnets make them ideal for use in MRI machines, where a strong and stable magnetic field is crucial for producing clear and accurate images.

4.Wind Turbines: Strong Neodymium Arc Segment Magnets are used in the generators of wind turbines to convert mechanical energy into electrical energy efficiently.

5.Automotive Industry: These magnets are used in various automotive applications, including hybrid and electric vehicle motors, sensors, and actuators, contributing to the advancement of modern automotive technology.

Advantages of Using Arc Magnets

The use of Arc Magnets, especially Neodymium Arc Magnets, comes with several advantages:

1.High Magnetic Strength: Neodymium Arc Magnets are the strongest type of permanent magnets available, providing exceptional magnetic force in a compact form.

2.Versatility: The curved shape of Arc Magnets allows them to be used in a wide range of applications, from industrial machinery to cutting-edge medical devices.

3.Durability: These magnets are highly resistant to demagnetization and can maintain their magnetic properties over time, ensuring long-lasting performance.

4.Efficiency: The strong magnetic field generated by Neodymium Arc Magnets enhances the efficiency of electric motors and generators, leading to improved performance and energy savings.

5.Customizability: With the ability to create Custom Neodymium Magnets, you can tailor these magnets to meet the exact specifications of your application, ensuring optimal functionality.

The Science Behind Neodymium Arc Magnets

Understanding the science behind Neodymium Arc Magnets is key to appreciating their incredible capabilities and widespread applications. These magnets are crafted from an alloy composed of neodymium, iron, and boron, forming what is known as NdFeB magnets. This specific composition is what gives Neodymium Arc Magnets their exceptional strength, making them the most powerful type of permanent magnets available on the market.

Preparation of the Alloy

The process begins with the preparation of the alloy. Raw materials—neodymium, iron, and boron—are meticulously measured and melted together. This molten mixture is then cast into molds to form ingots, which are subsequently cooled and solidified. The resulting alloy possesses the intrinsic magnetic properties necessary for the creation of Neodymium Arc Magnets.

Milling and Pressing

Once the alloy is prepared, it undergoes a milling process where it is ground into a fine powder. This powder is then pressed into the desired shape using a technique known as powder metallurgy. For Arc Magnets, the powder is pressed into a curved mold, creating the distinctive arc shape that fits seamlessly into various applications such as motors and generators.

Sintering

After pressing, the molded powder is subjected to a process called sintering. This involves heating the pressed powder in a furnace at high temperatures, just below its melting point. Sintering causes the particles to fuse together, resulting in a dense and solid magnet. This step is crucial as it enhances the magnetic properties and structural integrity of the magnet.

Coating

To ensure durability and longevity, Neodymium Arc Magnets are coated with a protective layer. Common coatings include nickel, zinc, or epoxy. This coating serves to protect the magnet from corrosion and oxidation, which can degrade its performance over time. The choice of coating depends on the specific application and environmental conditions in which the magnet will be used.

Magnetization

The final step in the manufacturing process is magnetization. The sintered and coated magnet is exposed to a strong magnetic field, which aligns the magnetic domains within the material. This alignment is what gives Neodymium Arc Magnets their powerful magnetic field. The strength and direction of this field are critical for the magnet’s performance in its intended application.

Tailoring to Specific Needs

What makes Neodymium Arc Magnets truly remarkable is the ability to customize them to meet specific requirements. By adjusting the composition of the alloy, the shape of the mold, the sintering conditions, and the type of coating, manufacturers can produce magnets with tailored magnetic properties. This level of customization is essential for applications that demand precise magnetic performance.

At MagnetsTek, we specialize in creating Custom Neodymium Magnets that meet the unique needs of our clients. Whether you require a specific shape, size, or magnetic strength, our team of experts can design and manufacture magnets that deliver optimal performance. Explore our range of custom solutions and see how we can help you achieve your goals with the power of Neodymium Arc Magnets.

Choosing the Right Arc Magnets for Your Needs

When selecting Arc Magnets for your application, it’s important to consider several factors:

Magnetic Strength: Determine the required magnetic strength for your application to ensure optimal performance.

Size and Shape: Choose the appropriate size and shape of the magnet to fit seamlessly into your device or assembly.

Coating and Durability: Consider the environmental conditions in which the magnet will be used and choose a suitable coating to prevent corrosion and enhance durability.

Custom Specifications: If your application has unique requirements, consider opting for Custom Neodymium Magnets to ensure the perfect fit and functionality.

Advancements in Arc Magnet Technology

The field of magnet technology is constantly evolving, with new advancements and innovations emerging regularly. Recent developments in the production and application of Arc Magnets include:

Improved Manufacturing Techniques: Advances in manufacturing processes have led to higher precision and consistency in the production of Arc Magnets, resulting in better performance and reliability.

Enhanced Magnetic Properties: Ongoing research and development efforts are focused on enhancing the magnetic properties of Neodymium Arc Magnets, making them even more powerful and efficient.

Eco-friendly Solutions: As environmental concerns continue to rise, there is a growing emphasis on developing eco-friendly manufacturing processes and materials for Arc Magnets.

Integration with Smart Technologies: The integration of Arc Magnets with smart technologies, such as IoT devices and sensors, is opening up new possibilities for advanced applications and improved functionality.

Custom Neodymium Magnets: Tailored Solutions for Every Industry

At MagnetsTek, we specialize in providing Custom Neodymium Magnets that meet the specific needs of various industries. Our team of experts works closely with clients to design and manufacture magnets that deliver optimal performance and reliability. Whether you’re in the automotive, medical, or renewable energy sector, our Custom Neodymium Magnets can help you achieve your goals.

Conclusion

Arc Magnets, particularly Neodymium Arc Magnets, are powerful tools that are transforming industries and driving technological advancements. Their unique shape and exceptional magnetic strength make them ideal for a wide range of applications, from electric motors and generators to medical devices and wind turbines. By opting for Custom Neodymium Magnets, you can tailor these magnetic marvels to meet your specific needs and achieve optimal performance in your applications. At MagnetsTek, we’re committed to helping you unlock the full potential of Arc Magnets and achieve success in your endeavors.

Explore our range of Custom Neodymium Magnets and discover how we can help you achieve optimal performance in your applications. Contact us today to learn more about our products and services.