Unlocking the Value: Recycling Magnetic Materials and Their Environmental Impact

In today’s world, where environmental sustainability is a pressing concern, the recycling of magnetic materials offers a unique opportunity to conserve resources and reduce environmental impact. Magnetic materials, essential in numerous applications, from consumer electronics to renewable energy technologies, are valuable and often contain rare earth elements. The process of recycling these materials not only helps in reclaiming these scarce resources but also minimizes the ecological footprint associated with their production. This article explores the importance of recycling magnetic materials, the processes involved, the role of magnetism in recycling, and the significance of custom solutions like Custom AlNiCo Magnets and Custom SmCo Magnets in advancing sustainable practices.

Understanding Magnetic Materials and Their Recycling Potential

Magnetic materials are critical in various industries due to their unique properties. Among these, neodymium, samarium-cobalt (SmCo), and aluminum-nickel-cobalt (AlNiCo) are prominent in the production of permanent magnets. These materials are prized for their strong magnetic fields, resistance to demagnetization, and stability at high temperatures. However, the extraction and processing of these materials are resource-intensive and environmentally taxing, involving significant energy use and the generation of waste.

Recycling these magnetic materials offers a pathway to mitigate these environmental impacts. The process involves recovering rare earth elements and other valuable components from discarded magnets, which can then be reused in manufacturing new magnets or other products. This not only conserves natural resources but also reduces the demand for new mining and refining activities, which are often associated with negative environmental consequences such as habitat destruction, water pollution, and carbon emissions.

The recycling of permanent magnets is particularly crucial because these materials are used in high-tech applications that are pivotal for modern society. For instance, neodymium magnets are integral to the manufacture of electric vehicles, wind turbines, and electronic devices, all of which are essential for the transition to a sustainable, low-carbon economy. By recycling these magnets, we can support the growth of green technologies while minimizing the ecological footprint of their production.

The Role of Magnetism in Recycling Processes

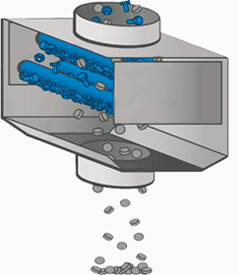

Magnetism itself plays a vital role in the recycling industry, particularly in the separation and recovery of ferrous metals. Magnetic separation is a technique used to sort magnetic materials from non-magnetic materials in mixed waste streams. This method is widely used in recycling facilities to recover metals like iron and steel from municipal waste, electronic waste (e-waste), and industrial scrap.

In the context of e-waste, magnetic separation helps recover valuable ferrous metals from electronic devices, which often contain a mix of metals, plastics, and other materials. This process not only facilitates the recycling of these metals but also reduces the volume of waste that ends up in landfills. Furthermore, it allows for the recovery of precious metals and rare earth elements from electronic components, which can be recycled and reused in new products.

Despite the effectiveness of magnetic separation, not all magnets can be easily recycled through conventional methods. For instance, placing magnets directly in the recycling bin is generally not advisable. Magnets can interfere with recycling machinery, potentially causing damage and disrupting the recycling process. Therefore, specialized recycling facilities or programs are often required to handle magnets, ensuring proper processing and recovery of valuable materials.

The Value and Challenges of Recycling Permanent Magnets

Permanent magnets, particularly those made from rare earth elements like neodymium and samarium, have significant scrap value due to their magnetic properties and the scarcity of these elements. The recycling of these magnets is essential for several reasons:

- Resource Conservation: Recycling helps conserve rare earth elements, which are crucial for many advanced technologies. Given the geopolitical complexities and environmental challenges associated with rare earth mining, recycling offers a sustainable alternative.

- Environmental Benefits: By recycling permanent magnets, we can reduce the environmental impact of mining and refining activities, which are often associated with significant ecological degradation, pollution, and greenhouse gas emissions.

- Economic Efficiency: Recycled materials often cost less than newly mined materials, providing economic benefits for manufacturers and consumers alike. Additionally, recycling reduces the dependency on supply chains that can be affected by geopolitical factors or market fluctuations.

However, the recycling of permanent magnets is not without its challenges. The main difficulties include:

- Technical Complexity: The process of recycling magnets involves separating the magnetic material from other components and impurities. This can be technically challenging and requires specialized knowledge and equipment.

- Economic Viability: The cost of recycling can be high, particularly if the magnets are embedded in complex products or if the market value of the recovered materials is low. This can make recycling economically unviable without regulatory incentives or technological advancements.

- Logistical Issues: Collecting and transporting used magnets for recycling can be challenging, especially when they are dispersed across various products and locations.

Custom Solutions: Custom AlNiCo Magnets and Custom SmCo Magnets

To address the challenges associated with the recycling of magnetic materials, custom solutions such as Custom AlNiCo Magnets and Custom SmCo Magnets have emerged as viable options. These solutions involve designing magnets with recycling in mind, using materials and manufacturing processes that facilitate end-of-life recovery and reprocessing.

Custom AlNiCo Magnets: AlNiCo magnets, composed of aluminum, nickel, and cobalt, are known for their stability and resistance to high temperatures. Custom AlNiCo magnets can be designed to meet specific requirements, making them suitable for various industrial applications. The recycling of AlNiCo magnets involves melting the magnets down to recover the constituent metals, which can then be reused in new magnet production or other applications. Customizing these magnets ensures that they are made with materials that are easier to recycle and can be efficiently recovered at the end of their lifecycle.

Custom SmCo Magnets: SmCo magnets, made from samarium and cobalt, are highly resistant to corrosion and oxidation, making them ideal for harsh environments. Custom SmCo magnets can be engineered for specific uses, such as in aerospace, medical devices, and other high-performance applications. The recycling of SmCo magnets is particularly important due to the scarcity and value of samarium and cobalt. By designing these magnets for ease of recycling, we can ensure that valuable materials are recovered and reused, reducing the need for new mining and refining activities.

The use of custom magnets also supports the development of a circular economy, where materials are continuously cycled back into production, minimizing waste and environmental impact. This approach not only conserves resources but also reduces the overall carbon footprint associated with the manufacturing and disposal of magnets.

The Future of Magnetic Material Recycling

As the demand for rare earth elements and other critical materials continues to grow, the importance of recycling magnetic materials will only increase. Advances in recycling technologies, combined with greater awareness and regulatory support, are key to overcoming the challenges associated with magnet recycling.

Future developments in this field may include:

- Enhanced Recycling Techniques: Improved methods for separating and purifying magnetic materials will make recycling more efficient and cost-effective. This includes advancements in hydrometallurgical and pyrometallurgical processes, as well as the use of solvents and chemical agents to recover rare earth elements.

- Product Design for Recycling: Manufacturers can play a significant role by designing products that are easier to disassemble and recycle. This includes using standard sizes and shapes for magnets, minimizing the use of adhesives and coatings, and providing clear labeling to identify magnetic components.

- Policy and Regulation: Governments can support magnetic material recycling by implementing regulations that promote recycling and discourage disposal. This may include extended producer responsibility (EPR) programs, which require manufacturers to take back and recycle their products, or incentives for businesses that use recycled materials.

- Consumer Awareness and Participation: Educating consumers about the importance of recycling and how to properly dispose of magnets and electronic devices can increase recycling rates and reduce the environmental impact of these materials.

Conclusion: A Sustainable Path Forward

The recycling of magnetic materials offers a promising path toward sustainability, resource conservation, and environmental protection. As industries and consumers become more aware of the importance of recycling, the demand for sustainable practices in the production and disposal of magnets will continue to grow.

By embracing custom solutions like Custom AlNiCo Magnets and Custom SmCo Magnets, businesses can lead the way in promoting recycling and reducing the environmental impact of their products. These solutions not only support the recovery and reuse of valuable materials but also contribute to a circular economy where resources are conserved and waste is minimized.

As we move towards a more sustainable future, the recycling of magnetic materials will play a crucial role in balancing technological advancement with environmental responsibility. By continuing to innovate and improve recycling processes, we can unlock the full value of these materials, ensuring that they contribute positively to our economy and our planet.